How to convert an energy-saving lamp into a 12 V power supply

Fluorescent energy-saving lamps (LESL) are becoming a thing of the past over time. They are being replaced by LED ones, which are simpler, more modern and environmentally friendly. LESL have a much shorter service life compared to an LED lamp. In 90 percent of cases, LESL fails due to the bulb; the electrode heaters in it break. The electronic filling itself is ready to easily work for decades. In this master class we will share an idea on how to convert a circuit into a 12 V power supply to power, say, an LED strip.

What we need for work:

- A board with parts from a burnt energy-saving lamp.

- Soldering iron with solder.

- Knife.

- Radio components: diode (for example, 1N5399) and 100 nF 400 V film capacitor.

- Copper wire 0.5 sq. mm.

- Tester - http://alii.pub/62t1zq

DIY power supply from an energy-saving light bulb

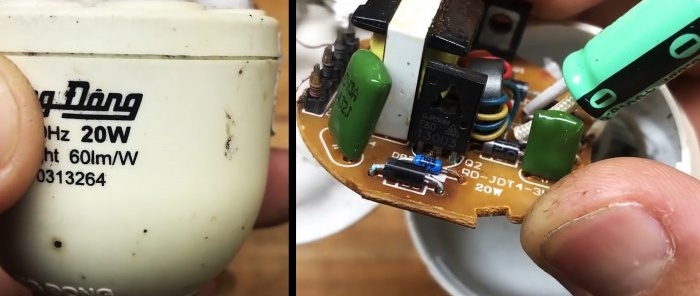

So let's get started. We take a non-working lamp (for example, 20 Watt) and open its plastic case with a knife.

We are convinced that the lamp failure is due to a burnt-out spiral of the bulb (do not forget to dispose of the bulb accordingly).

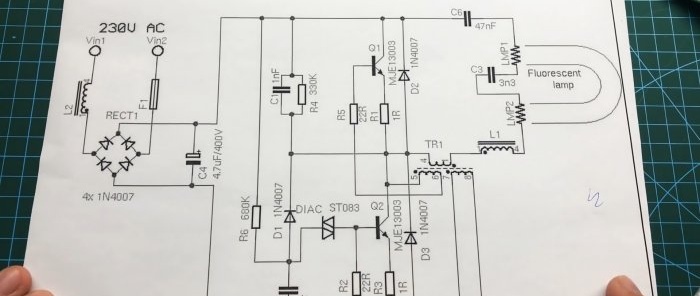

You can easily find a diagram for a lamp on the Internet by the name of the brand and print it on a piece of paper.

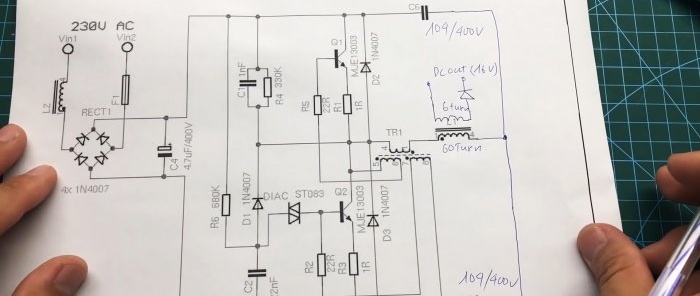

And make changes to it: remove the spiral and one of the high-voltage capacitors from the sketch, add a rewound transformer with a diode and a film capacitor.

Next, we solder one of the film capacitors (on the board it’s C4), and then the transformer.

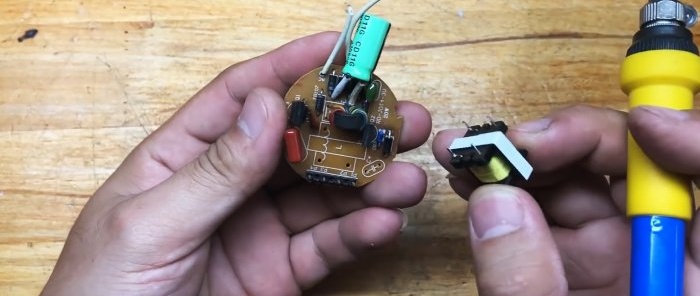

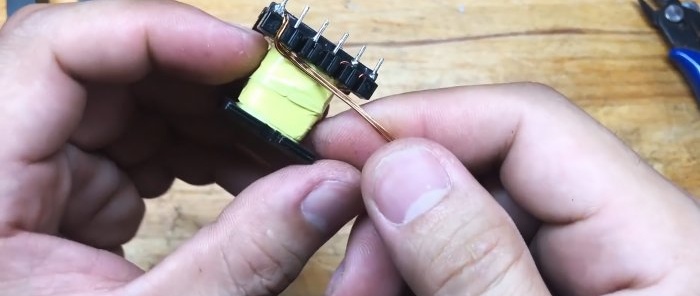

We rewind the transformer coil: the primary – 60 turns of wire with a cross-section of approximately 0.5 square meters. mm, and the secondary - 6 turns of the same wire, but folded into four cores.

We solder two wires to the pins on the secondary side.

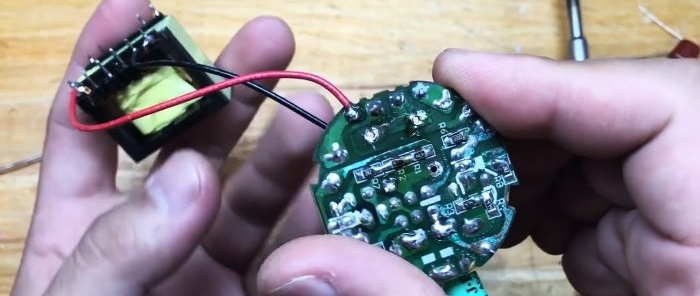

We solder one of the wires to the corresponding transformer terminal on the board, and the second to one of the terminals of the non-polar capacitor C3.

We find the plus and minus on the board on the primary side and solder a new film capacitor - one leg to the ground, and the second to the terminal of the C3 film capacitor left in the circuit.

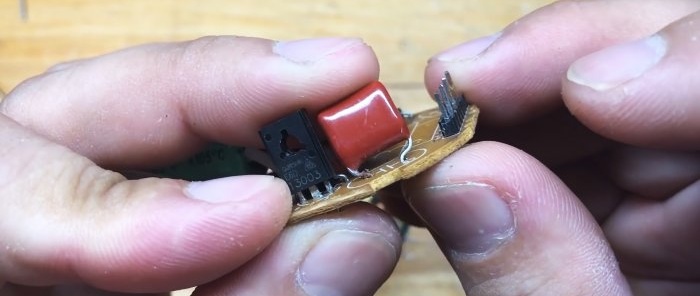

Next, take the diode and connect it to the output transformer. Ready!

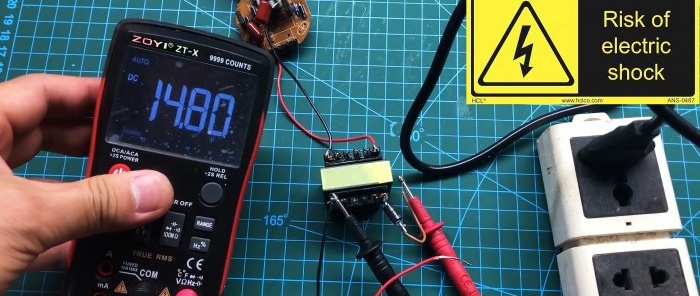

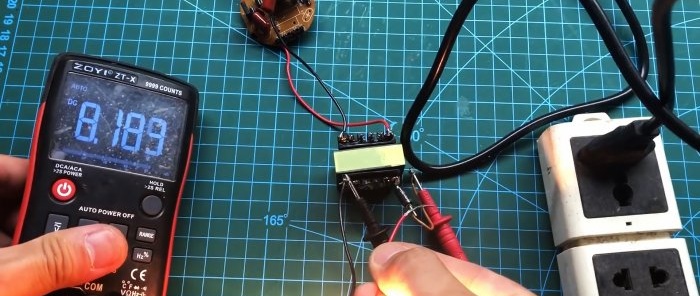

You can supply 220 Volts, and at the same time connect a tester to check the system. Without load, it shows a constant voltage of 12-15 Volts.

We connect a 35 W light bulb, and the value drops by almost half!

Well, as for other uses of the device, you can connect a single-phase motor to it - it works like a clock.

This source can be successfully used as a charger, as a driver for power supply LEDs, LED strips, etc. In general, wherever there are no serious requirements for voltage stabilization.

Multimeters on AliExpress at a discount - http://alii.pub/62t1zq

Watch the video

Similar master classes