How to make a concrete mixer with a folding mechanism from a barrel

For serious construction, you need a large, reliable concrete mixer. If the budget is very limited, in order not to save on building materials, you can not buy a concrete mixer, but hand it over yourself from a steel barrel and scrap metal.

Materials:

- steel barrel 200 l;

- bearings with bushings – 2 pcs.;

- profile pipes (which exist);

- threaded rod equal to the inner diameter of the bearings;

- wheels with brackets – 2-4 pcs.;

- corner;

- electric motor reducer;

- thick roller chain with sprocket;

- switch or speed controller.

Concrete mixer manufacturing process

Assembly must begin by converting the barrel into a concrete mixer drum. To do this, you need to measure its circumference and mark the walls on the side of the lid into 16 identical parts. Then the top of the barrel is cut off, and longitudinal cuts are made along the marks to the stiffeners. On one side, each petal must be cut at the same angle. The cut segments from the top of the barrel must be folded inside the circle under the cone and brewed.

A frame for installing the drum is welded from a profile pipe, consisting of two legs on a wide sole. The dimensions are not particularly important, the main thing is stability, the only thing is that for ease of work it is better to make it 80 cm high.

To attach the drum, you need to prepare a pipe of the same length as the width between the frame posts, and weld bushings onto it on both sides in the center. The walls between the bushings are drilled out. Bearings are pressed into them. Then a glass or nut with a stud is welded to the center of the bottom of the barrel from the outside. The latter is inserted into the bearings and tightened with nuts.

Next, you need to weld a traverse for tipping the concrete mixer. To do this, 2 tubes with a length reaching to the end of the lower ribs of the barrel are welded to the pipe with the pin on the drum. Along the edges, a piece of pipe is welded to them to create an axis of rotation. Then pieces of pipes spread out lengthwise are welded to the ends of the racks to form cups for supporting the axle. Thus, after this the drum can be laid on the frame.

Another frame is welded at a right angle down from the traverse. Small wheels are installed on it to rest against the drum. Also, a section of profile pipe is welded upward to the pipe opposite the bearings at a right angle, which will serve as the basis for installing the power button.

Inside the barrel, it is necessary to weld blades from a corner for scooping concrete. They will provide more efficient and faster mixing.

On the left of the drum, a long lever is welded to the traverse with wheels to tilt the mixer when pouring concrete. At the bottom, opposite the bushings with bearings, a long leg is welded to rest against the sole bridge. She will hold the drum, preventing it from tipping over on its own.

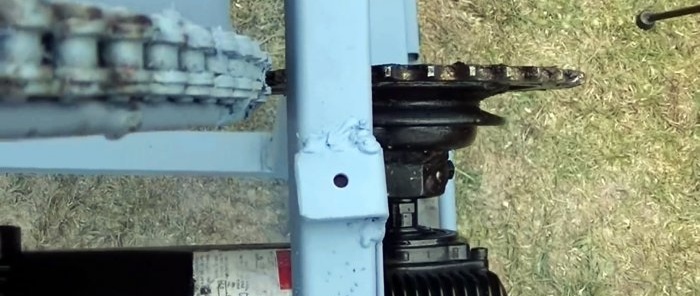

A roller chain is welded around the circumference of the drum bottom.

Behind it, a gear motor with a sprocket is attached to the frame so that its teeth grip the chain. The engine is covered on top with a casing cut from a plastic bucket. A switch or speed controller is installed on a vertical tube on the traverse.

To ensure airtightness, it is better to place it in a plastic box.

Before starting the concrete mixer for the first time, it is necessary to double-check whether the support leg is long enough so that the drum does not tip over when loading and the concrete does not splash out. For greater reliability, you can weld a folding stopper to the traverse, which can be used to rest against the frame to block tipping. Adding stability will also result in counterweights. If everything is in order, you can start mixing the concrete. The finished solution is drained from the drum by pressing the lever down, with preliminary tilting of the blocker, if it was installed.

Watch the video

Similar master classes

How to make a cheap concrete mixer from a barrel

New barbecue from an old barrel

Making a mobile stove out of a barrel for burning garden waste

How to make a barbecue grill from a barrel

Making a tandoor from a barrel with an insulated bottom without mortar

How to make a mini-cellar from a barrel in a garage or country house

Particularly interesting

How to install a socket if there are short wires left

How to eliminate gaps between the chimney and slate

How to mix an ultra-reliable solution for the oven that does not give

There will be no more cracks: What to add to concrete to make it

Never buy ball valves without checking with me

New technology for floor insulation with penoplex

Comments (0)