How to make a compact and powerful pulse soldering iron

A pulse soldering iron differs from a regular one in that it heats up almost instantly. It can be used within a few seconds after being plugged into the network. At the same time, the pulsed version is economical, has a small size and allows you to use a voltage from 6 to 12 Volts. You can connect such a soldering iron via a power supply, phone charger or from a car cigarette lighter.

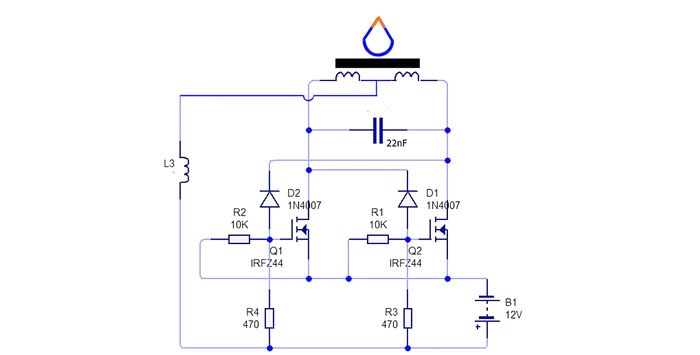

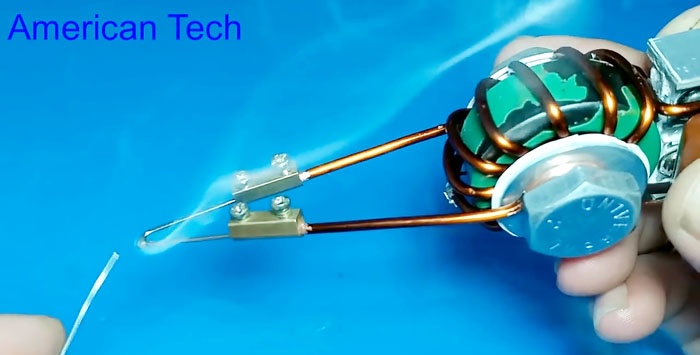

This device is made according to the “push-pull self-oscillator” circuit. The main element of the soldering iron is a transformer, the secondary winding of which is made of one turn of thick wire. The ends of the coil are closed through a thin tip, which is why this particular area heats up.

To make a pulse soldering iron we will need:

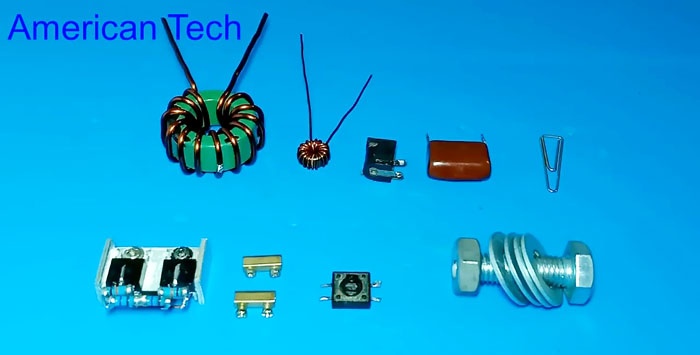

- ferrite core;

- 2 resistors at 470 Ohm;

- 2 resistors 10 kOhm;

- 2 rectifier diodes 1N4007;

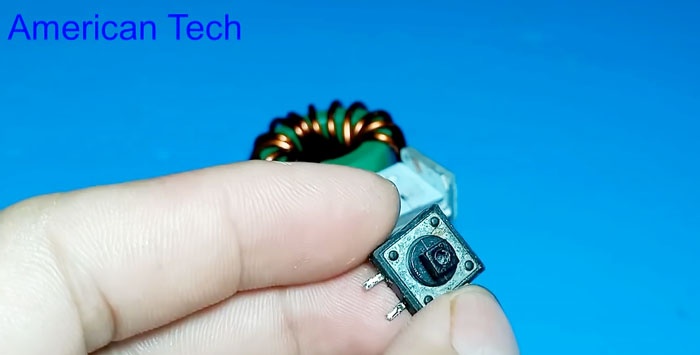

- 2 field-effect transistors IRFZ44;

- capacitor 22 nF;

- inductance (choke) 47 μH;

- power button;

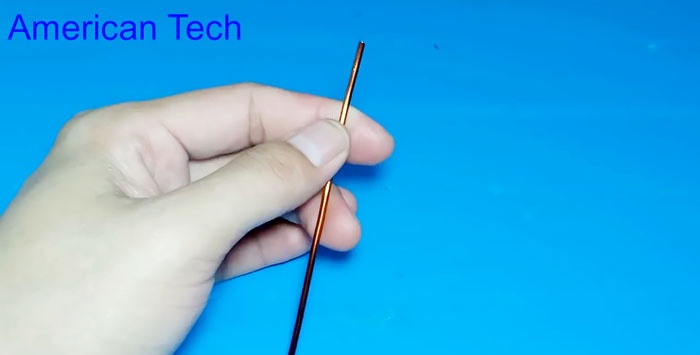

- copper wire, 2 mm thick;

- connector for power supply;

- metal terminal blocks;

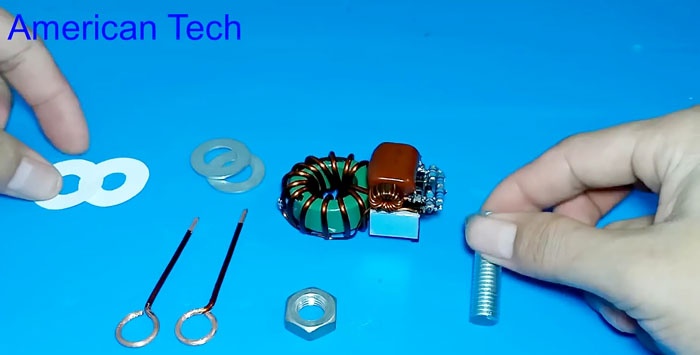

- bolt, nut, 2 metal washers, 2 washers made of insulating material;

- clip.

Let's start assembling the pulse soldering iron:

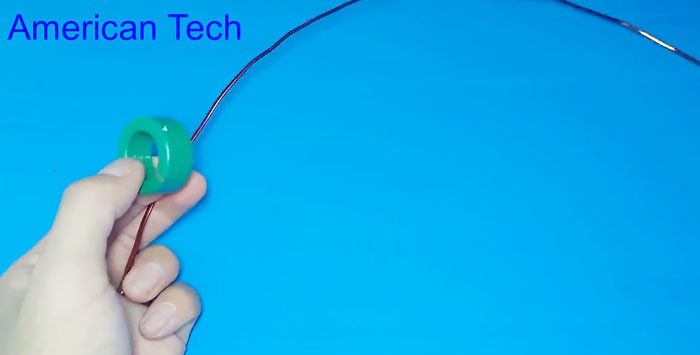

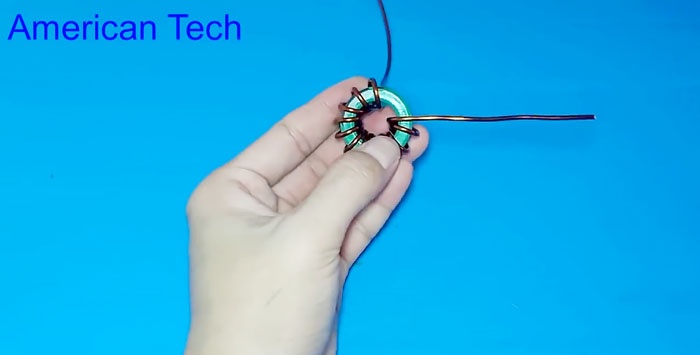

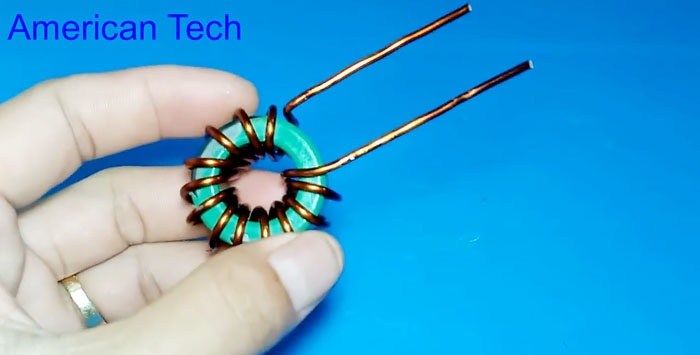

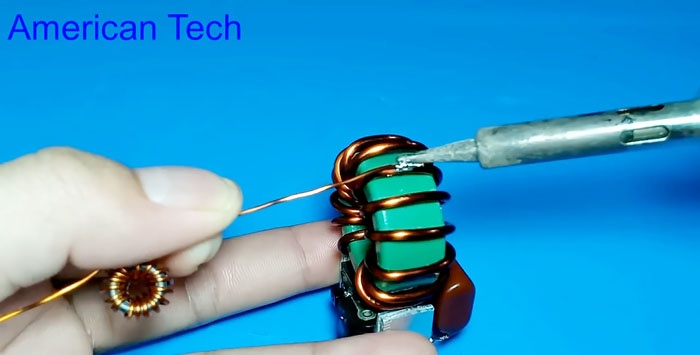

1. First, let's make a transformer. For this we need a ferrite core and a copper wire 2 mm thick. We make 12 turns of wire.

The ends of the winding are removed and cleaned.

2. Field-effect transistors in this circuit may overheat.

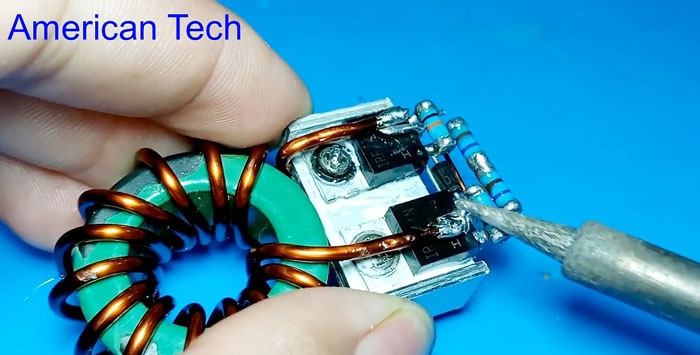

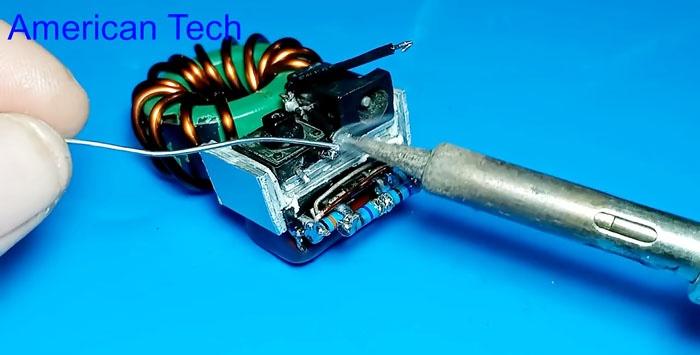

Therefore, they must be connected to a heat sink. You can use any metal part as a radiator. To make the device compact, the heat sink can be used as the skeleton of the circuit. We assemble the main radio components around it. We solder resistors and diodes.

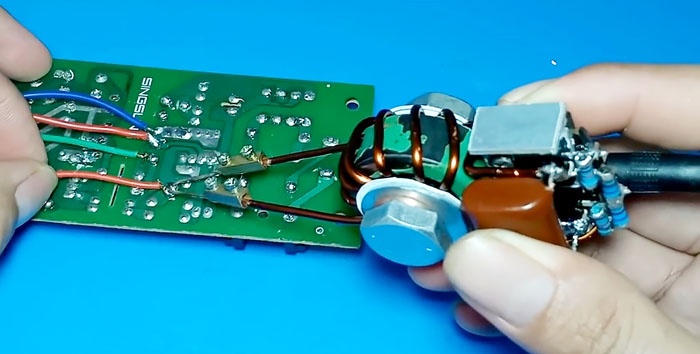

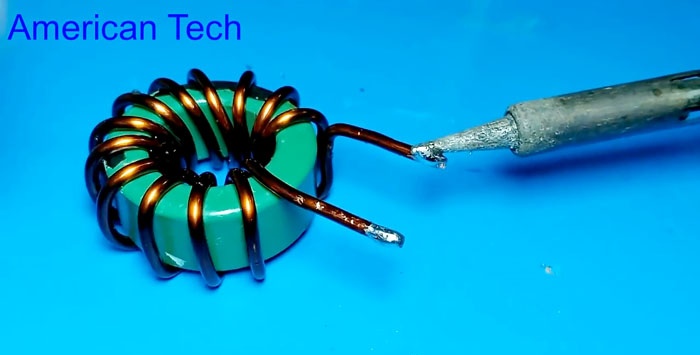

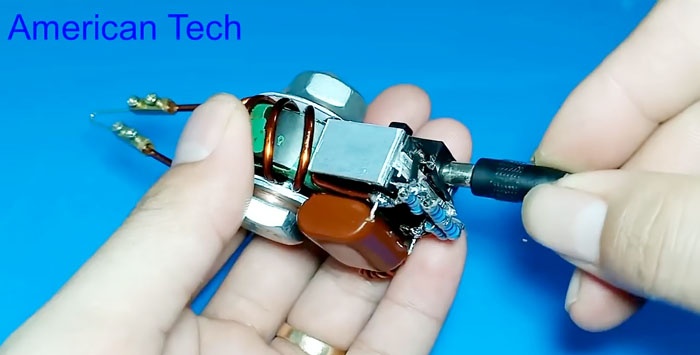

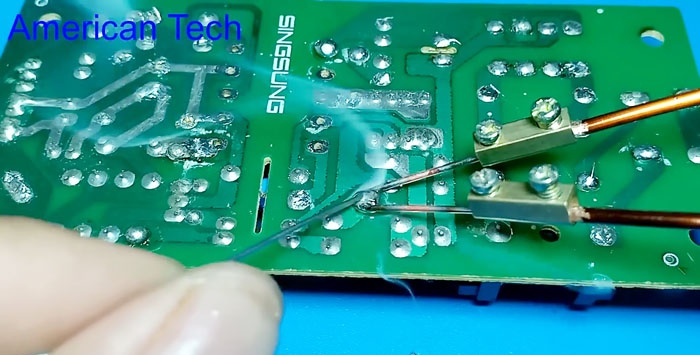

3. Solder the ends of the transformer winding and the capacitor to the resulting board.

4. On the back side we glue the power button and connector. Then solder it. The power button must be non-latching. That is, the soldering iron will work when the button is held in the on position. This is done so that when turned on for a long time, the entire transformer will heat up and holding the soldering iron in your hands will be problematic.

5. Find the center of the winding and solder the inductor.

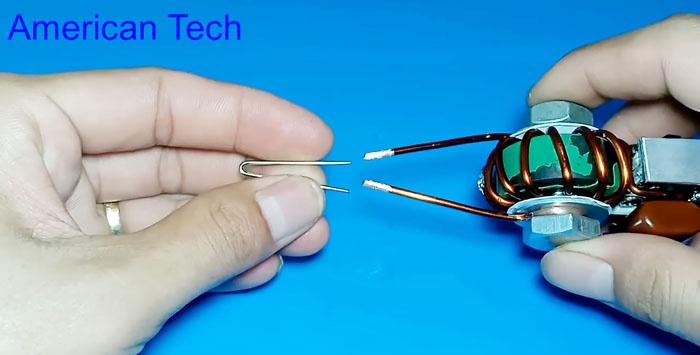

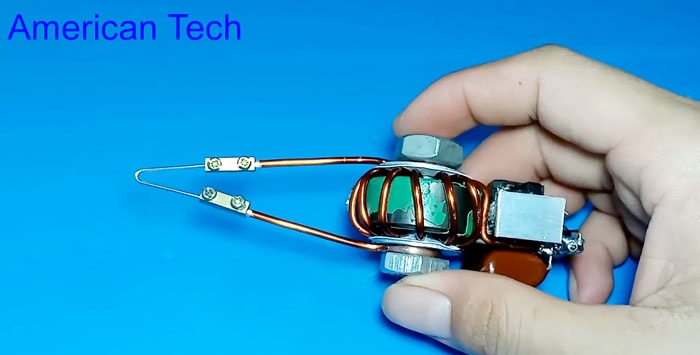

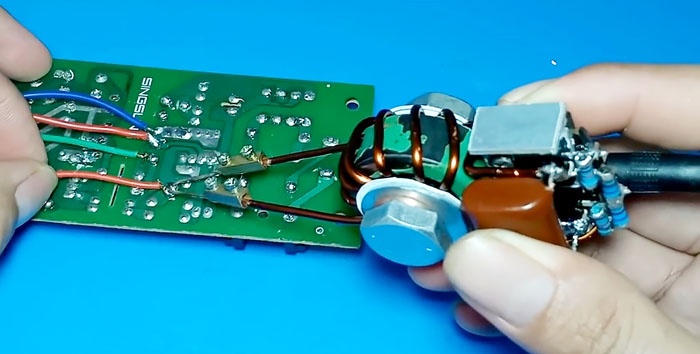

6. Assemble the secondary winding. We make two conclusions from a wire 2 mm thick.

We clean the ends from varnish. On one side we make rings to match the diameter of the bolt.

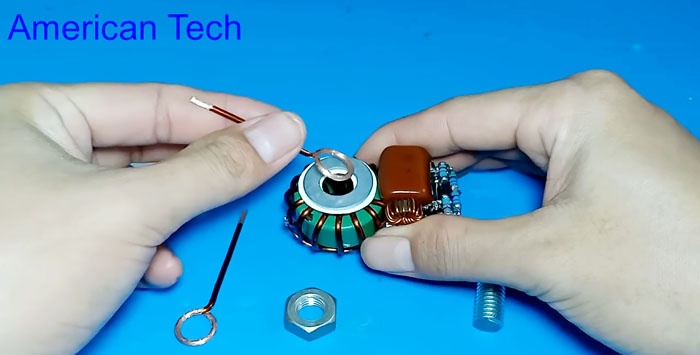

7. We put one of the wires on the bolt, then a metal washer and insulation. We insert the bolt into the hole in the transformer. We put on the insulation, the washer, and the second contact. We tighten it with a nut.

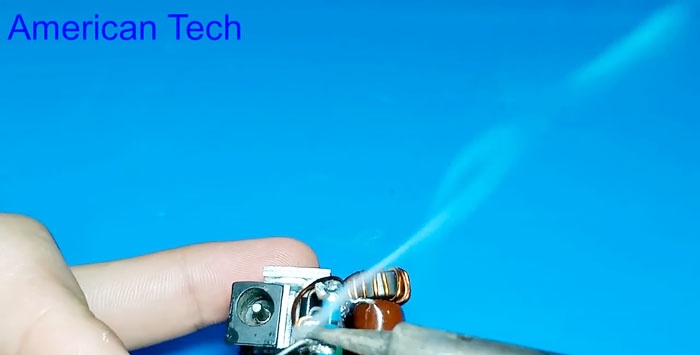

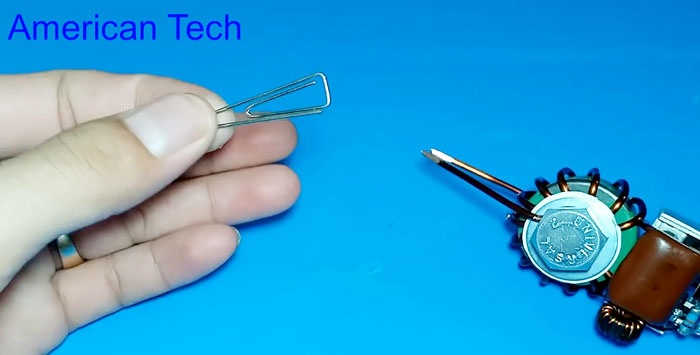

8. We cut the paper clip to make a comfortable tip.

And connect to the terminals of the secondary winding using terminal blocks.

9. Connect the soldering iron to the power source. We check the functionality.

Note

You can connect a pulse soldering iron from various power supplies with voltages up to 12 Volts.It must be taken into account that the higher the voltage of the unit, the greater the power of the device and the faster it will warm up.

This soldering iron can be powered by batteries or rechargeable batteries. In order to achieve a voltage of 12 Volts, the batteries must be connected in series. A soldering iron is a very powerful device, so it won’t last long on batteries. However, due to the rapid heating, it is quite sufficient for small volumes of work. The main thing is not to forget to turn it off.

Safety precautions

- When connecting the soldering iron to the power source, observe the polarity.

- After assembly and performance testing, it is better to hide the soldering iron circuit in the case.

- Remember to unplug the device after use.

Watch the video

Similar master classes

Particularly interesting