DIY hand sharpener made from old gears

Working with power tools and power machines is certainly very convenient and fast, but there are times when only manual equipment can help out, for example, when there is no electricity. For such cases, you can make the most necessary equipment in advance. Let's look at how to assemble a manual emery machine (sharpener) with your own hands.

Materials:

- Large and small gear;

- emery wheel;

- blank for turning;

- steel strips 20 mm, 50 mm;

- steel plate 5-10 mm.

High-quality and durable drills on AliExpress at a discount - http://alii.pub/5zwmxz

The process of making hand emery (sharpener)

To make the nozzle, you will need to select 2 gears with the same tooth size. The larger one of them is relative to the second, the higher the machine speed will be.

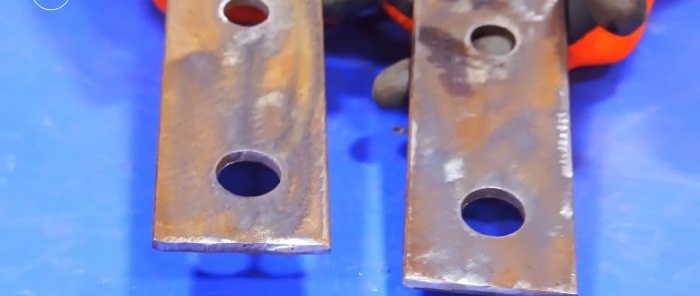

We join the gears, and based on their size, we cut 2 blanks for the frame from a strip 50 mm wide.

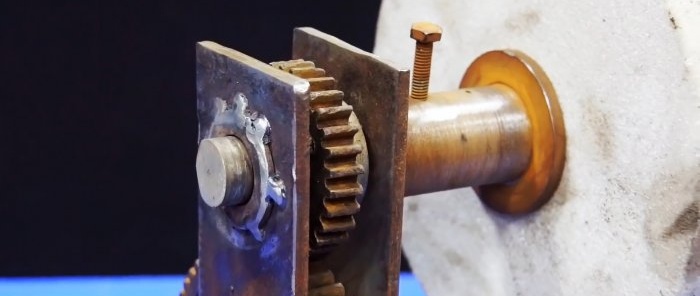

Using a lathe, you need to turn the axles with seats for the gears. They are provided with steps to provide clearance when installing the shafts into the frame made of strips.

Then we mark the stripes along the gears and drill them for the machined axles.The holes are made 1 mm larger so that the latter can rotate freely.

The axles and gears are welded.

Now you need to install the gears with axes between the strips. Moreover, the protruding parts of the axes must be directed in different directions.

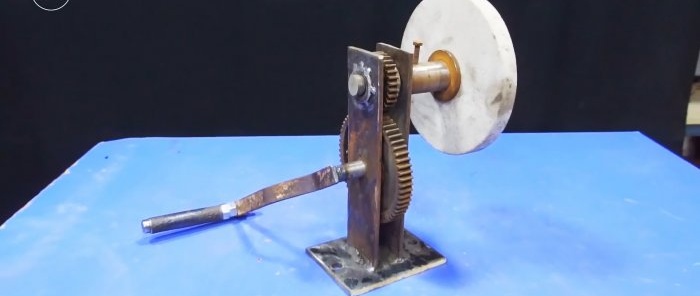

The resulting structure is welded onto a steel plate base.

A handle bent from a thin strip is welded onto the axis of the large gear. The handle itself is a thin tube placed on a pin made from a hairpin.

An adapter for the grinding wheel on the small gear shaft is turned on a lathe. With its help, the abrasive is fixed. After this, the machine is screwed with the sole to the table.

As a result, we get a very simple and trouble-free sandpaper. They can easily sharpen knives, chisels and other tools. To make it work smoothly and more or less quietly, do not forget to periodically lubricate the gear teeth.