How to make a simple and reliable sprinkler from PP pipe

For uniform irrigation and watering of plants in the garden or vegetable garden, it is very convenient to use sprinklers, sprinklers or sprinklers. This method of watering does not require physical energy expenditure and when using a water timer, the process can be fully automated. To save a lot of money, you can make simple sprayers with your own hands from a polypropylene pipe. They perfectly distribute the water flow 360 degrees. Having provided your area with such sprinklers, it is very easy to water the plants with one turn of the shut-off valve.

For production you will need:

- 1 meter of polypropylene pipe with a diameter of 25 mm, two plugs and one tee;

- 15 cm polypropylene pipe with a diameter of 40 mm (preferably thick-walled);

- metal sleeve 10-15 cm, internal thread on both sides;

- adapter;

- soldering iron and a simple gas burner.

Water timers on AliExpress at a discount - http://alii.pub/66xxxg

Making a sprinkler with your own hands

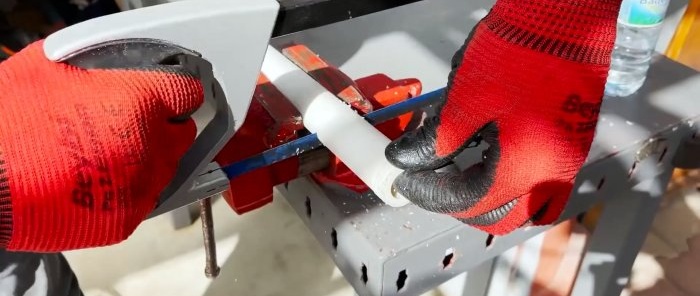

We heat the nut with a torch and use it to cut a thread on a piece of 40 mm pipe.By the way, in this case, you can use a simple “American”.

When cutting threads, immediately cool with water to prevent the thread from being “licked off”.

We cut off a 0.5 cm washer from the same pipe and carefully clean it of burrs.

We take two pieces of 25 mm pipe, each 30 cm long.

We seal each piece on one side with a plug, and on the other side we solder it into a tee. We cut another piece of the same pipe, 2-3 cm longer than the fortieth pipe, and solder it into the free end of the tee.

We first install a piece of the 40th pipe, then our stripped plastic washer.

By pressing it to a heated soldering iron, we melt the tip of the short 25th pipe and ensure that the resulting structure rotates freely on the 40th pipe.

We drill the side sections and plugs with a drill in different directions. The diameter of the drill should not exceed 3 mm (it’s better to try 1.5 or 2 mm first; it’s never too late to increase).

We screw a metal sleeve onto a piece of 40 pipe.

Using a gas burner, we achieve a smooth bend of the sides of the sprayer.

We screw the “American” into the other end of the bushing, then screw it into the stand adapter.

After connecting the hose and supplying water, by rotating under pressure and thanks to the holes in different directions, watering occurs over a fairly large area and does not require constant transfer of the sprayer.

Watch the video

Similar master classes