How to make a device for turning cylindrical workpieces without a lathe

Round wood blanks are usually turned on lathes. Not every home workshop has such expensive equipment. But it can be replaced with a simple device made from accessible and inexpensive materials, which any adult can make.

Will need

Materials:

- sheet of multilayer plywood;

- strips made of multilayer plywood;

- screws, screws and bolts;

- wing nuts;

- flat and engraving washers;

- wooden blocks and slats;

- housing bearings;

- cylindrical shaft-rod.

Tools: circular saw, drilling machine, nail gun, drill, open-end wrenches.

The process of making a device for turning round wooden rods

We mark a rectangular sheet of multilayer plywood and make a system of holes equidistant from the edges and at an equal distance from each other.

We place two strips of multilayer plywood into the grooves of the circular table and lay a plywood sheet on them, aligning all the edges.We fasten them with nails from a nail gun. We strengthen the resulting structure from below with screws. We make sure that the guides slide easily in the grooves of the circular table.

We lay the plywood sheet face down on a transversely located wooden block, align the edges and connect with screws.

We lay the second side of a sheet of multilayer plywood on the same block and, using two holes in it, drill through holes in the block. We connect the sheet and the block with two screws, washers and wing nuts.

High-quality and durable drills on AliExpress at a discount - http://alii.pub/5zwmxz

We place the resulting structure with guides into the grooves of the circular table and cut a through slot along the entire length in the center of the sheet.

The third block, analogous to the first two, can be secured anywhere on the plywood sheet using bolts and wing nuts.

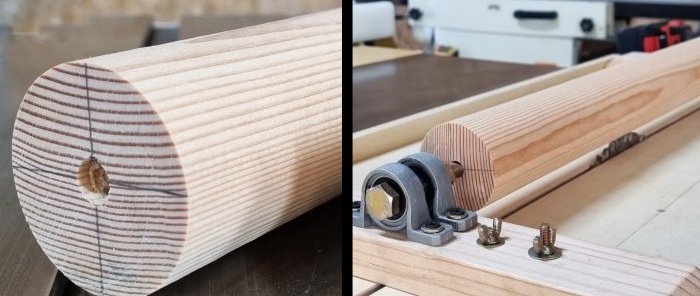

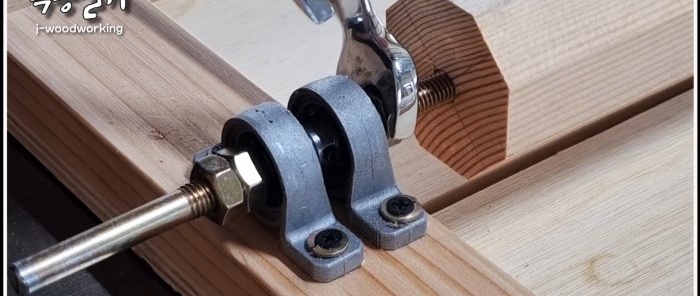

We fix the intermediate block in one position, place on it and the fixed block two housing bearings in the center, connected by a shaft-rod, and fasten them with screws through the engraver to the bars. Remove the shaft-rod.

We cut off the head from a long bolt and sharpen the end of the rod into a flat cone. We do the same with the short bolt, but do not touch the head.

We insert a short bolt into the housing bearings on a movable block outside of the stationary one and secure it with two nuts.

We insert the pointed end of the long bolt rod into the housing bearings on a stationary block and screw the nut on the outside. Screw two nuts onto the free end of the rod.

We fasten strips of multilayer plywood to the long edges of the plywood sheet with nails.

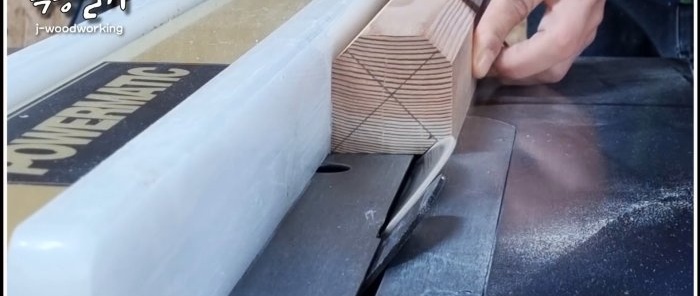

To facilitate the process of turning square blanks into cylindrical longitudinal edges of wooden blanks, we remove them with a circular saw.

We make centering recesses at the ends of the workpieces and place them between the pointed ends of the bolts in the bearing units. By tightening the nuts, we create an axial force so that the workpieces do not turn during processing.

We place the circular disk with the required reach at the middle bar. Then use a drill to rotate the workpiece using the bolt shaft and turn on the circular saw. The disk, rotating and moving along the workpiece, transforms the initially non-round workpiece into a cylindrical rod.

By changing the position of the middle block on the plywood sheet and the offset of the disk, we obtain round rods of different lengths and diameters.