How to weld two metal pipes of different diameters

Sometimes at home or at work there is a need to urgently connect two metal pipes of different diameters when a suitable coupling, adapter or flange is not at hand. In such a situation, you can use a fairly simple method that does not require special tools or professional training.

Will need

Materials and tools:

- two pipes of different diameters;

- marker, ruler and square;

- Bulgarian;

- welding machine or soldering iron;

- bench vice;

- hammer and pliers.

Long-lasting discs for angle grinders on AliExpress at a discount - http://alii.pub/61bjly

The process of joining two metal pipes of different diameters in the absence of fittings

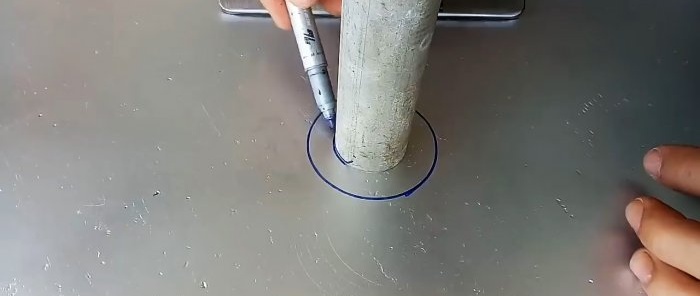

We draw two concentric circles with a marker on a flat and hard surface, alternately tracing the pipes from the outside that we are going to connect to each other.

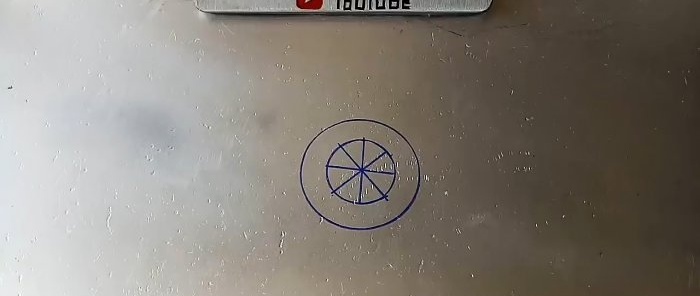

Using available means, we divide the smaller circle into 8 equal parts, first drawing two mutually perpendicular diameters, and then two more of the same diameters, but shifted by 45 degrees.

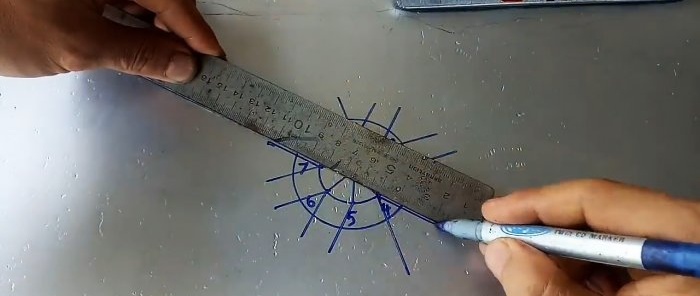

We normalize the points of intersection of the ends of the diameters with the circle with numbers from 1 to 8.Then we alternately apply a ruler to points 1 and 6, 1 and 4, 2 and 7, 2 and 5, 3 and 8, 3 and 6, 4 and 7, 5 and 8, and draw straight lines from the points connected by the ruler beyond the outer circle.

We shade the areas limited by the straight line segments extending from each number and the arc of the outer circle enclosed between them.

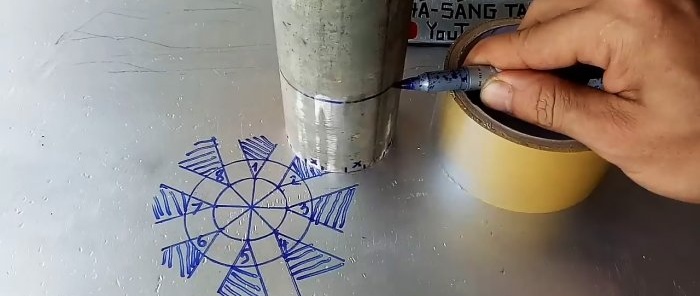

We install a pipe with a large diameter on the outer circle and mark on its generatrix the beginning and end of each shaded area in the figure. We mark these arcs on the pipe with crosses.

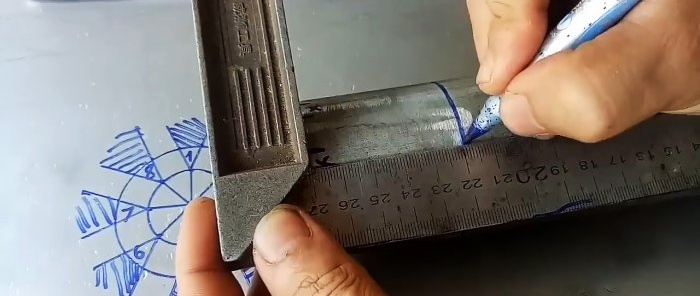

At some distance from the end with the marks applied, draw a circle on the surface of the pipe parallel to the end.

Using a square, we transfer the projections of the points of the centers of the sections marked with crosses at the end of the pipe to the circle drawn above.

We connect the points of the ends of the sections at the end of the pipe with the corresponding point on the circle.

As a result, we get 8 triangles on the surface of the pipe, which we cut out with a grinder.

We make shallow cuts on the outside of the pipe at points around the circumference where the tops of the cutouts are located to facilitate bending inward the “petals” at the end of the pipe.

We clamp the pipe in the jaws of the vice and, hitting the “petals” from the outside one by one with a hammer, tilt them towards the center. The final bending adjustment of the “petals” is carried out using pliers.

We place the end of the pipe of smaller diameter against the octagon formed by the “petals” and make sure that they match exactly.

We complete the connection of two pipes of different diameters by welding or soldering process.

Watch the video

How to make a threaded connection of polypropylene pipes of different diameters - https://home.washerhouse.com/en/7630-kak-sdelat-rezbovoe-soedinenie-polipropilenovyh-trub-raznogo-diametra.html

Similar master classes