Homemade diode analogue from simple accessories

An electronic device such as a rectifying diode can be created at home using available tools and knowing the processes of chemical reactions. Since the operation of the device is based on passing electric current in one direction and blocking it in the opposite direction, the experiment uses the ionization of metals in a liquid and the movement of electrons between electrodes.

How to make a chemical diode from a syringe

To create a unidirectional flow of electrons, two metals with different electrical activities will be required. Copper, silver, iron, aluminum, aluminum oxide, etc. are suitable. A regular 5 ml medical syringe is used as a container. The piston is removed and the sealing washer is removed.

A small hole is drilled in it, which will be used to fix the central electrode.

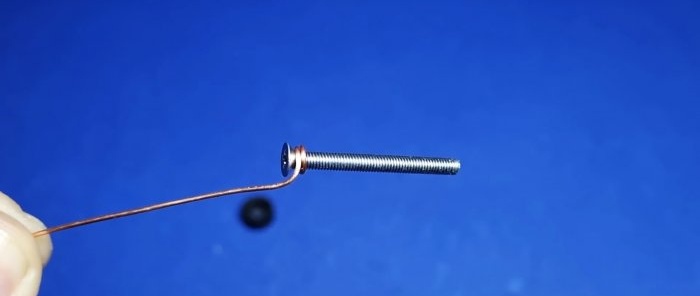

The role of the electrode in this case is played by an iron screw, to which a piece of copper conductor is connected before installation.

The screw is inserted into the sealing washer and secured with a nut.

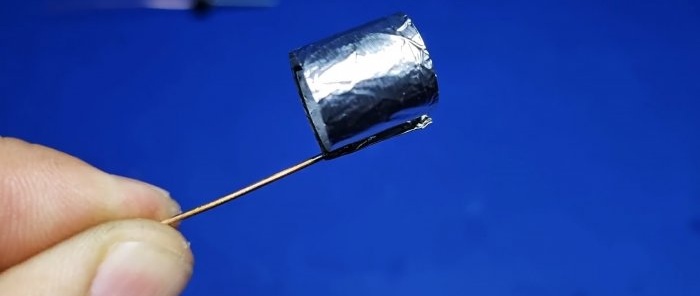

Next, take a piece of sheet aluminum foil (you can use a chocolate bar).It is folded three or four times into a strip 15-20 mm wide and 150-200 mm long.

The strip is wound onto the marker to form a solenoid. It plays the role of the second electrode.

A piece of copper wire is also attached to the foil.

The entire “structure” is carefully inserted into the body of the syringe so that the wire comes out through its nose.

To obtain a seal, the nose of the syringe is heated over a fire until it melts.

Now the plunger is inserted into the syringe so that the end of the screw is in the center of the foil cylinder.

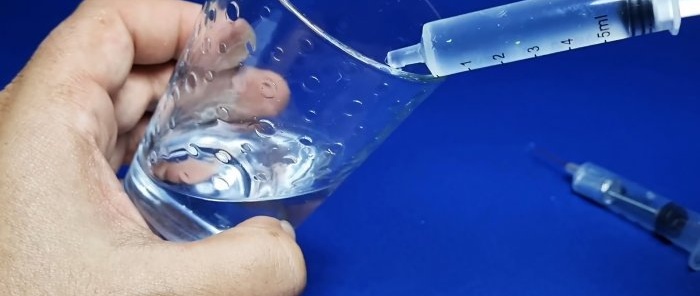

A small hole is made in the body of the syringe. To do this, it is convenient to use a soldering iron tip. To prepare the electrolyte, take a third of a glass of water and sodium carbonate powder (carbon dioxide salt). Using another syringe with a needle, the container is filled with the prepared solution.

For safety, the hole is filled, although this may not be necessary, so that the gases produced escape.

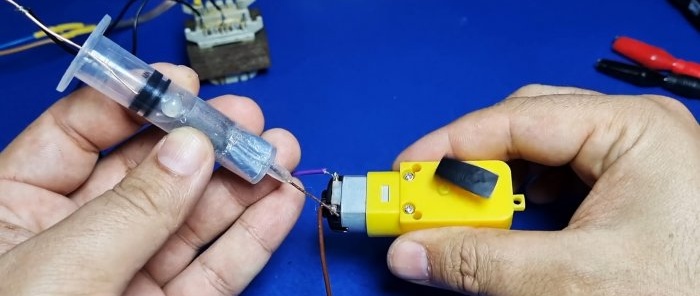

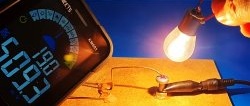

Due to the difference in the activity of the metals, a unidirectional flow of electrons is formed between the screw and the foil. Electrolysis results in the separation of hydrogen molecules, so caution is required - it is explosive. The operation of such a one-way electrolytic rectifier can be seen clearly using a direct current micromotor (DC-motor operating from 12V. For this, the diode is connected through a transformer to the alternating current network.

Using multimeter you can verify the signal parameters at the output of the transformer. It has the required voltage, but the current is alternating.

Therefore, when a motor is connected directly to it, the armature does not rotate or moves jerkily.

When the assembled element is connected to the circuit, the motor begins to rotate, since the input signal on it changes to a half-wave DC generated by the diode.

From this we can see that the assembled device limits the lower ones in one direction, and the upper ones when connected in the opposite direction. By turning it at the other end, you can change the direction of rotation of the motor. The element can also act as a one-way bridge due to the ions given off to the water. Its operation is short-term, until the water in the solution splits into hydrogen and oxygen, and this is only an analogue of a diode, since its resistance on one side and the other differs by an order of magnitude, and not a million times, like that of a real diode. Nevertheless, it performs the function of half-wave rectification, as can be seen from the experiment.