How to connect a round pipe with a square profile, make a transition

In some situations in a home workshop or even at work, it becomes necessary to connect a profile square pipe with a round pipe that is obviously larger in cross section. This can be done in different ways. Let's consider one of them that any adult can implement.

Will need

Materials and tools:

- round pipe of large diameter;

- smaller profile square pipe;

- paper strip 24x5 cm;

- marking and measuring equipment;

- grinder with cutting disc;

- mechanic's hammer.

The process of preparing the end of a large round pipe to connect to a small square pipe

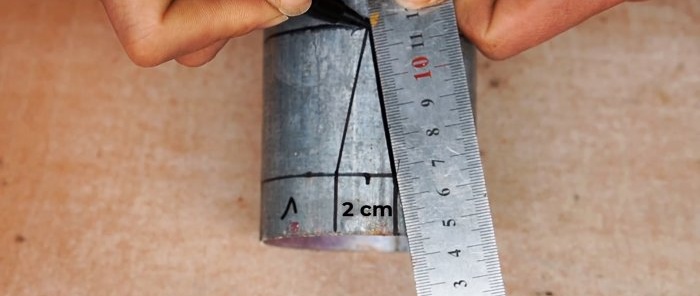

Outside the round pipe, set aside 2 cm from the end and put a mark.

We take a paper strip measuring 5 by 24 cm and make sure that it matches the outer circumference of our round pipe.

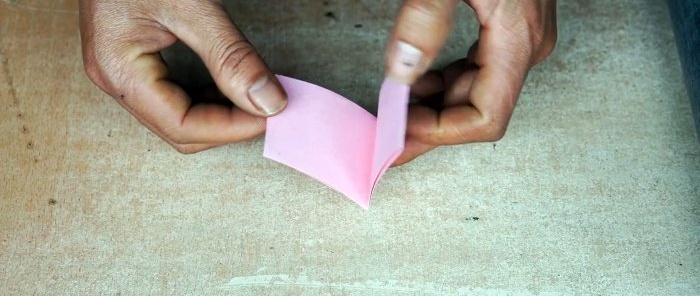

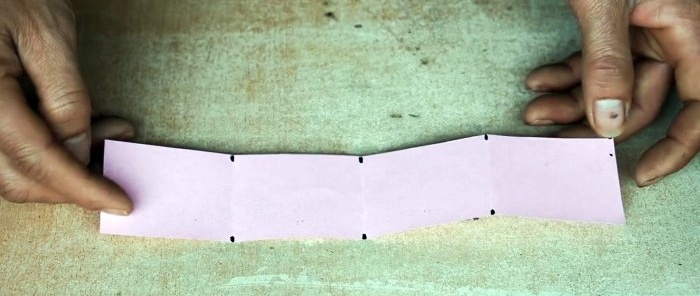

Fold the paper strip twice along its length, as accurately as possible. We mark with dots the three vertical lines resulting from double addition at the bottom and top, as well as on both sides of the strip.

We cover the outer surface of the pipe with a marked strip so that its ends are connected along a line passing through the mark, spaced 2 cm from the end of the pipe.

We transfer all the marks on both sides of the paper strip to the surface of the pipe and simultaneously draw two circles using its sides. The circles should have four matching marks.

We measure the side of the square pipe, which is 4 cm. We measure the circumference of the pipe between adjacent marks, which turns out to be 6 cm.

From each of the four marks we put 1 cm along a circular arc in both directions and from their ends we draw straight lines to the end of the pipe, the distance between which will be 4 cm.

Four sections at the end of the pipe with a circular arc of 4 cm are marked with a tick. From points spaced 1 cm from the first four, draw straight lines to the corresponding points on the second circle. We mark these triangle areas with crosses.

Long-lasting discs for angle grinders on AliExpress at a discount - http://alii.pub/61bjly

Using a grinder, cut out 4 sections marked with crosses. Along the circumference more distant from the end of the pipe, we make a blind annular recess.

Bend the four sections (petals) marked with checkmarks towards the center of the pipe, hitting their ends with a hammer. In this case, the bending occurs along the annular recess made earlier with a grinder.

We continue the deformation until the adjacent sides of the petals come together, and a square is formed at the end, exactly corresponding to the cross section of the profile square pipe for the connection.

We place the square pipe against the square of the round pipe and make sure that they completely coincide.After this, the round and square pipe can be welded or soldered, resulting in a strong and airtight connection.