How to make a cone at the end of a round pipe

For independent production of screw piles for the foundation of buildings, driven fence posts for fencing a dacha or farmstead, strength and decorative elements of gates, wickets and for some other cases, it is necessary to make a correct and complete cone at the end of a round pipe, that is, to sharpen it. To do this, we do not need expensive materials, complex and special tools, highly qualified performers, just the ability to handle an angle grinder.

Will need

- round metal pipe;

- thick sheet of paper;

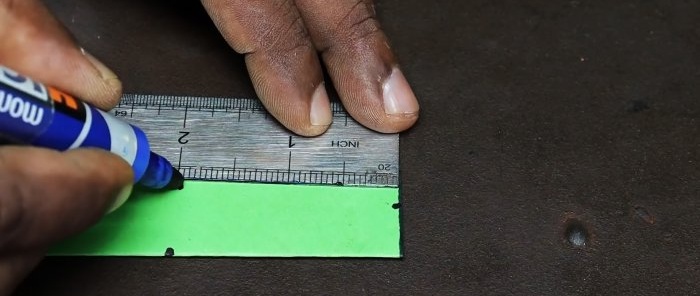

- marker and metal ruler;

- scissors;

- rubber ring;

- Bulgarian;

- hammer, etc.

Welding electrodes for general purposes on AliExpress at a discount - http://alii.pub/606j2h

The process of making a cone at the end of a round pipe

We cover the pipe along the cylindrical surface with a sheet of thick paper and mark with a marker the position of the edge of the sheet on it.

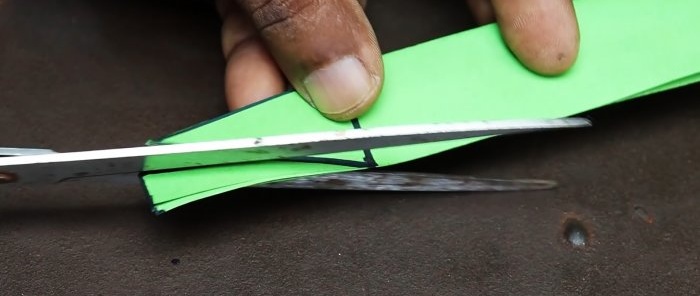

We bend the paper sheet along the marks and cut off with scissors the part that went to the circumference of the round pipe.

We fold the separated part of the sheet of paper in half parallel to the long side twice, aligning the edges, and measure the width of the resulting paper strip, which will depend on the diameter of the pipe. In our case it was 33 mm.

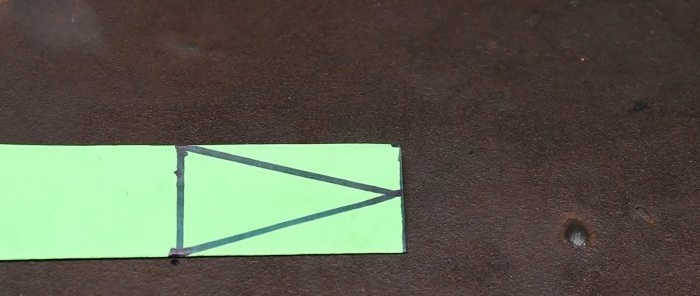

We mark the middle of the strip on its edge, measure down a distance of 49.5 mm (33 mm × 1.5), draw a transverse line and from its ends draw straight lines to the middle point on the edge of the strip.

We cut off the resulting outer triangles with scissors, unfold the paper strip and again cover the pipe with it, aligning the resulting tops of the “teeth” with its end along the entire circumference.

We strengthen the paper girth with a rubber ring on the metal pipe and trace the paper “teeth” along the outer surface of the pipe with a marker.

We fix the pipe with the markings in a bench vice and cut out the “teeth” with a grinder in the amount of four pieces.

We wrap the base of the “teeth” with a paper sheet with an overlap, ensuring that the edges match, draw a circle with a marker and make transverse cuts along it between the “teeth”.

Under the blows of a hammer, we bend each “teeth” along the cross-section of the base until the “teeth” meet with their apexes in the center of the pipe.

A pipe sharpened in this way in some cases (for example, for decorative purposes) can be used as received, but to increase the strength of the end cone (screw piles, driven fence posts, etc.), the contact lines of the “teeth” can be welded, the seams treat and paint with a protective compound.

Watch the video

Similar master classes