How to make your own mold for casting plaster wall tiles

Purchasing ready-made gypsum wall tiles, depending on the quantity required, is associated with large monetary costs. But you can cast it yourself if you first make an appropriate mold from silicone, and this does not require special skills or expensive materials.

Will need

Materials:

- drywall residue;

- master model of wall tiles;

- PVA glue;

- formwork made of transparent plastic;

- liquid silicone;

- catalyst;

- gypsum mortar, etc.

Tools: spatulas, glue gun, toothbrush, wallpaper knife, plastic cups, container for liquid plaster.

Process of making silicone mold and casting gypsum wall tiles

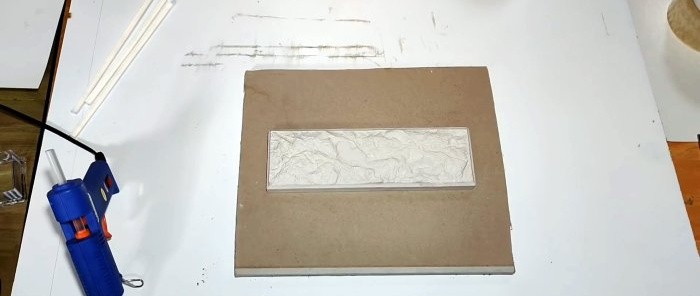

We cover the bottom of the master model of wall tiles with glue along the contour and glue it to the surface of the drywall. Carefully push back the glue that has come out from under the model with a spatula. We simply remove the excess.

We place a rectangular formwork made of transparent plastic around the master model, trying to ensure the same gap around the entire perimeter, and also glue it to the drywall using a glue gun.

Pour liquid silicone into a disposable plastic cup, add one cap of catalyst and thoroughly mix the components until a homogeneous mass is obtained, which is indicated by the same color of the mix throughout the entire volume of the cup.

Pour the contents of the glasses into a form made of transparent plastic, trying to avoid any spillage until it is completely filled. We wait some time for the silicone to spread over the entire formwork and its surface to assume a horizontal position.

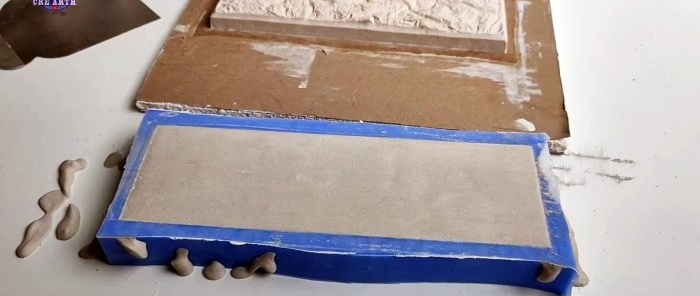

Then we cut the glue with a knife and remove the transparent formwork from the transparent plastic. Then carefully separate the hardened but flexible silicone mold from the drywall and master model at one end.

We dilute the gypsum solution in a container of suitable volume and pour it into a silicone mold, periodically lifting individual sections of the mold for better filling and removal of air. We continue the process until the mold is completely filled with gypsum mortar.

Then smooth the surface of the gypsum mortar with a flat spatula. Remove excess plaster. Leave the plaster in the mold for 15-20 minutes so that it sets. But we must remember that it will take 12 hours for it to completely harden in a warm and dry room.

After waiting the specified time, we turn over the silicone mold with the set plaster inside and, holding one edge of the mold, carefully remove it. This operation is easy, because the plaster has hardened, and the silicone mold is flexible and does not adhere to the plaster.

As a result, we obtain a copy of the master model of gypsum wall tiles, which can be used for wall cladding in any room with a normal level of humidity.

Watch the video

Similar master classes

Particularly interesting