How to make a multifunctional corner corner from completely affordable materials

In a home workshop or at work, when assembling metal products, precise installation and reliable fixation of one part relative to another is often necessary. These operations take a long time and require constant attention. By making a multi-functional 2-in-1 corner clamp from affordable and simple materials, the installation and fixing operations of parts are greatly accelerated and simplified, while ensuring high accuracy.

Will need

Materials:

- round steel pipe;

- bolts and nuts;

- equal-flange steel angle;

- steel strip;

- steel bars.

High-quality and durable drills on AliExpress at a discount - http://alii.pub/5zwmxz

Tools: ruler and marker, drill, grinder, sandpaper, welding, magnetic holder, etc.

Manufacturing process of a 2-in-1 multi-functional corner clamp using available materials

We measure a distance of 60 mm from the end of a round pipe with a diameter of 75 mm and make a mark. We draw a line from the mark to the pipe cut along the generatrix. Place a mark in the middle of the line and drill through holes in the wall, located at the ends of the diameter.

Using a sheet of paper, draw semi-arcs on the pipe along the edges of the holes and a ring line at the 60 mm mark. Drill cut out along the semi-arcs, make a half ring between the holes and separate the workpiece 60 mm wide. Clean the edges with sandpaper.

From the equal angle corner we cut two identical fragments 60 mm long and one, pressing the ends of the shelves to the ring and blocking the slot somewhat, weld to the ring.

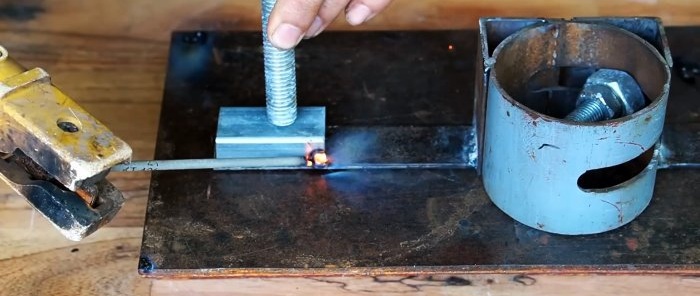

We press the narrow side of the steel plate to the base of the shelf of the corner, which does not overlap the slot in the ring, and weld it. Second corner with the same welded We press the strip against the ring so that one edge of the corner flange comes into contact with the edge of the corner welded to the ring.

On the other edge of the shelf of the second corner we place a mark that coincides with the center of the ring slot. Focusing on this mark, we place a bolt inside the corner along the bisector of the inner corner of the rolled metal and weld its head to the corner.

We insert the bolt rod into the slot of the ring and put on a large nut from the inside, which we press with a nut similar in thread to the bolt.

We weld steel bars longitudinally to the outer edges of the plates. We lay the bolts with two screwed nuts longitudinally on the bars so that the outer edges of the nuts coincide with the ends of the bars and in this position we weld the nuts to the bars, having previously wrapped the threads of the bolts with tape.

We weld bolts with smaller nuts transversely to the ends of the clamping bolts to make it easier and more convenient to rotate them when fixing the workpieces.

We paint the structure and it is ready for use.

A fixed clamp serves to fix the device on the base part, and with the help of a movable clamp, the workpiece is installed and fixed at a given angle.

Welding electrodes for general purposes on AliExpress at a discount - http://alii.pub/606j2h

Watch the video

Similar master classes