4 useful lifehacks for soldering and soldering irons

In some cases, it is very difficult or completely impossible to solve a specific problem related to soldering with a conventional soldering iron and classical soldering methods. But with some ingenuity, you manage to cope with an unexpected problem. Below are 4 surprisingly interesting life hacks on the topic of soldering and soldering irons, some of which you will undoubtedly find worthy of attention and subsequent use.

1. How to reliably solder twisted copper or aluminum wires

We perform back-to-back twisting of stranded wires. We fix the twist between the clamps and cover it with flux.

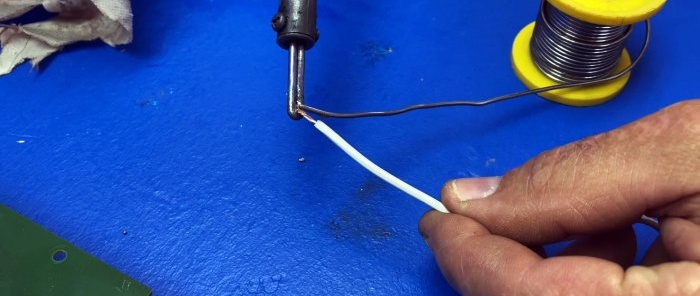

We bring the elongated and flat tip of the switched-on soldering iron under the twist, and place the end of the solder wire between the soldering iron tip and the twist. Due to the heating of the twist and surface tension forces solder penetrates through the entire cross-section of the twist along its entire length.

After the soldering area has cooled, we put a heat-shrinkable casing on it, which we burn with the flame of a gas burner.

2. How to reliably solder twisted wire without a soldering iron

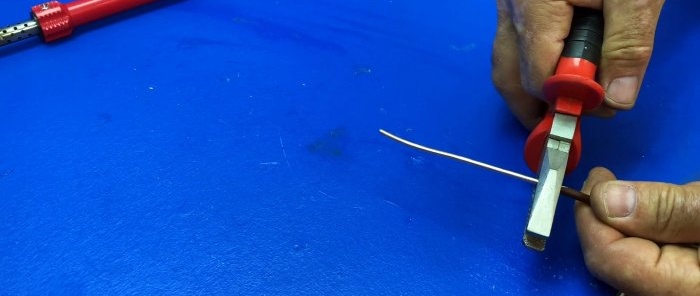

Flatten the end of the solder wire into a narrow strip using a hammer and anvil.

We wind it in the form of a spiral over the insulation of one of the twisted wires. We twist the wires, apply flux and move the solder winding onto the twist.

We heat the solder spiral in the flame of a gas lighter until it completely melts, but without dripping.

After waiting for some time, we slide the heat-shrinkable casing over the twist and set it in the flame of a gas burner.

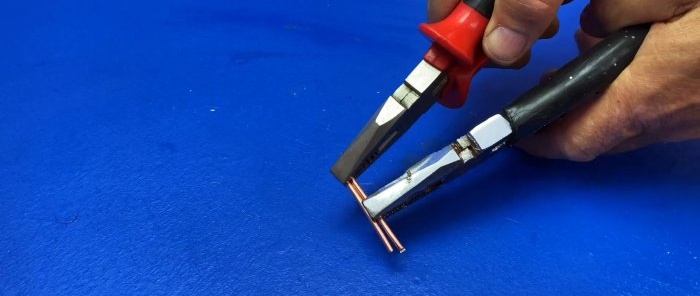

3. How to upgrade a soldering iron tip to work with a printed circuit board

Loosen the fastening screws on the soldering iron body and remove the standard tip. Instead, install aluminum wire bent in half with its forked side and tighten the fastening screws.

Now, using a tip in the form of a wire loop with a bent end, it is convenient to solder the “legs” of the elements without affecting the adjacent elements of the printed circuit board.

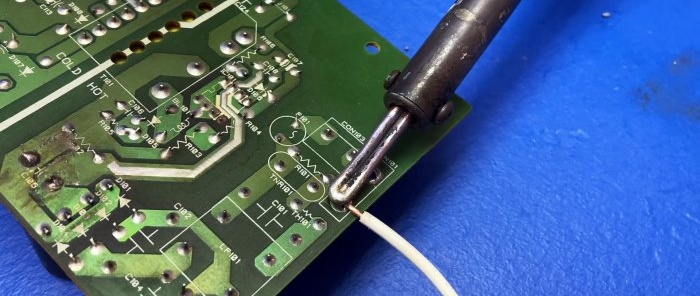

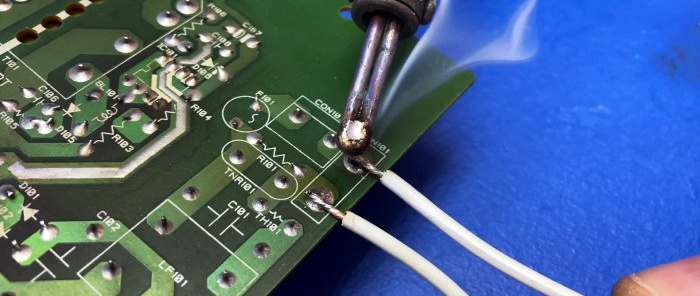

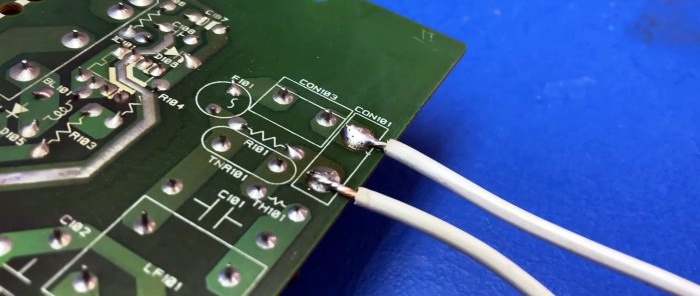

4. How to neatly and securely solder a wire to a printed circuit board

It is difficult to reliably solder a wire that has not been tinning beforehand to a printed circuit board without damaging it. Therefore it is necessary, melting solder loop-shaped tip of the soldering iron, while tinning the soldered wire. The resulting soldering is neat and reliable due to the balancing of surface tension forces.