The concrete floor in the garage will not dust and crumble if you cover it with a homemade composition

Today, construction stores offer various special products for treating concrete floors to prevent spalling and excessive dust release. But folk remedies are also known to combat this phenomenon. Let's try to use a well-known life hack from the Internet and explore its pros and cons. So.

For processing concrete screed with an area of 15 square meters. we will need:

- polystyrene foam 2 sheets of 1 sq. m, thickness 50 cm;

- acetone 2 liters;

- xylene 1 liter;

- color.

The idea is to dissolve the foam and cover the concrete floor in the garage with this composition, adding color to it for beauty. Begin.

1. Dissolve the foam

To dissolve polystyrene foam, the Internet recommends using acetone. This advice is probably from ancient Soviet times. Then the foam was different or the acetone was stronger. The fact is that modern polystyrene foam does not dissolve in acetone. It is possible that the recipe for its manufacture has been changed - now only non-flammable material is produced.

It didn’t work with acetone, so we tried dissolving it in xylene. Luck. Polystyrene foam dissolves easily and effortlessly.Just don’t try to add acetone to the solution - the foam forms unsightly viscous lumps.

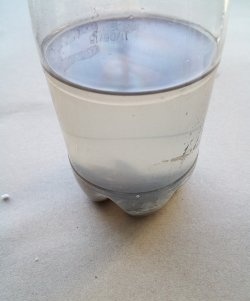

After dissolving the entire volume of foam and adding color for aesthetics, we got about 3.5 liters of liquid, similar to thick varnish.

2. Applying the composition to the floor

We carefully sweep the concrete floor and begin to apply the composition with a regular paint brush. Dissolved polystyrene foam is actively absorbed by concrete, the consumption of the product is very large. 3.5 liters was only enough for half the garage - approximately 7 square meters. m area in one layer. And in the future the processing will probably need to be repeated - the thickness of the coating is clearly not enough.

The product obtained by dissolving polystyrene foam in xylene has a very pungent odor. Even working in a respirator does not save you from the consequences - headache, unpleasant taste in the mouth. Therefore, to continue the experiment, ordinary 95 gasoline was taken as a foam solvent. The floor in the garage was completed, and the quality of the work was assessed after a month of use.

Results

Pros:

- no chipping;

- no dust.

Minuses:

- strong unpleasant odor;

- high labor costs;

- When solvent or gasoline spills, the coating sticks to the shoes and peels off from the concrete.

As a result, we can say that the disadvantages of this method outweigh its advantages. And the most reasonable means for carrying out this kind of work is a special primer. It honestly performs its functions, has no unpleasant odor and costs very little money.