How to wash a gun with polyurethane foam at a fraction of the cost?

When a gun with a screwed-on cylinder, in which there is still unused polyurethane foam, is simply put aside, then even after a short time the foam inside the gun will dry out and it will be difficult to use it again.

To prevent such a problem from happening and the gun can be used after any, even quite a long time, after finishing work, you just need to tightly tighten the foam release regulator, located above the handle on the top on its outer side.

But still, if the mounting foam inside the gun has dried out, you will have to wash it using an expensive can of special “OPPA” type washing liquid. It costs quite a lot. What to do if the canister has run out of such liquid, and it’s too far to run to the store or it’s already closed?

Making a reusable rinsing bottle

Let's use an empty can and turn it into a reusable one. This will save significant money.

But to do this, first, by pressing the valve button, we will bleed off the residual air that is still in the can, for safety reasons.

Next, we drill a hole with a diameter of 5 mm in the center of the bottom, into which we will insert an appropriately prepared bronze nipple from a car tube or tire with a short valve.

We cut off the thick rubber part from the nipple, and burn the rubber coating on the remaining part of the nipple in the flame of a gas burner.

We clean the bottom of the can around the previously drilled hole with emery cloth, etch the metal with soldering acid and tin it near the hole. We repeat the same with the seat of the shortened nipple.

We insert the nipple into the hole and seal it in a circle, making sure to ensure both mechanical strength and hydro-gas tightness.

Using a medical syringe, pour approximately 100 ml of solvent 646 into the balloon through the nipple and screw in the nipple.

We also supply air into the cylinder through the nipple using a compressor or even a hand bicycle pump. For our case, 4 atmospheres is enough.

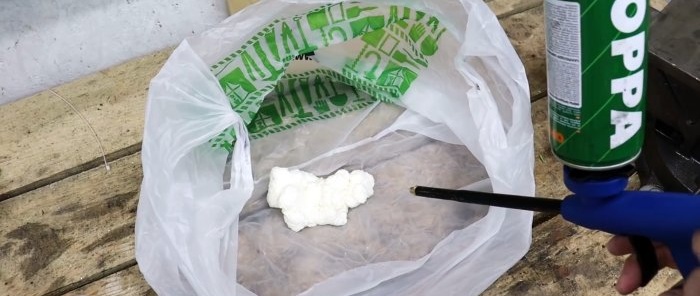

We install a container with solvent instead of a container with polyurethane foam, unscrew the foam release regulator and pull the trigger. Dissolved foam begins to release intensively from the gun nozzle. We continue washing until only colorless solvent begins to come out of the nozzle.

Instead of solvent 646, you can also use white spirit or acetone under pressure up to 6 atmospheres to clean the gun from dried polyurethane foam.

Watch the video

Similar master classes

Particularly interesting