How to make chic front door slopes from regular laminate

After correct installation of the entrance door, an equally important operation is the installation of slopes, which, along with decorative functions and convenience, give the entrance group a finished look. The master will have to pay a tidy sum for such work. But it can be performed by any adult holding the simplest woodworking tools in their hands.

Will need

Materials:

- laminate panels;

- construction foam;

- Double-sided tape;

- decorative corners.

Tools: tape measure, square, pencil, jigsaw, masking tape, utility knife, spatula.

The process of manufacturing high-quality and attractive entrance door slopes from laminate

The width of the slopes for a standard 90 cm entrance door is 28 cm. Of course, the dimensions may be different, but this does not change the essence of the matter. We will attach the upper slope strip behind the door frame, since there is room for this. Due to the bolts and welded structure, the side strips will have to be attached directly to the door frame.

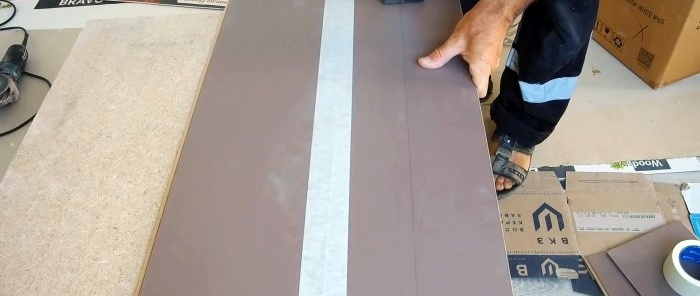

We begin the installation of slopes by marking the laminate panel under the top bar.We saw off 2 pieces of equal length, since the width of the laminate is 19.5 cm, while the width of the slope is 28 cm.

We snap the locks of the sawn-off laminate strips and cover the contact lines on one side and the other with masking tape to prevent the lock from opening. Then we install the top plank blank to the slope at the place for fitting, mark the cutting line on the surface of the laminate and saw off the excess.

Before installing the top strip in place, we make rollers from construction foam so that they better press the laminate against the door frame. For convenience and to free your hands, we temporarily hammer finishing nails along the edges to support the panel.

We place the foam deep into the slope at intervals so that when it hardens, the panel does not squeeze out. We foam the outer edge of the slope with a continuous thin line. After pressing the panel, we fix it several meters away with masking tape.

To temporarily fix the sloped sides to the door frame, we will use scraps of laminate with glued strips of double-sided tape. Using a square, we measure the angle of rotation of the side panels, which turned out to be 3 mm greater than the right angle at the end of the slope.

We glue laminate scraps to the door frame to temporarily fix the side panels. Mark the cutting line on the panel along the edge of the slope. We saw off the excess, having first disassembled all the laminate strips.

On the side walls in the depths of the slope, as well as at the top, we apply support foam rollers, giving them time to set and initially harden. We apply foam to the outer edge of the slope, press the shelf and secure it with masking tape.

We apply decorative corners and secure with masking tape. We trim the corners with a utility knife using a spatula and break off the excess along the cut.We repeat the same with the other corner. The result is a perfect connection, and ultimately excellent slopes.

Watch the video

Similar master classes

Particularly interesting