What does the use of citric acid and other washing machine “cleaners” lead to?

Modern washing machines are reliable devices that rarely fail due to design flaws or low-quality components. But the true “scourge” of automatic washing machines is corrosion. Destruction of the tank cross occurs much more often than the need to replace, for example, bearings. Which liquids are most active in corrosive destruction? A story about experiments with metals from washing machines from different manufacturers.

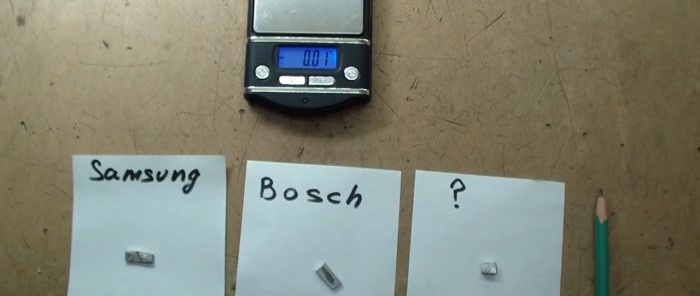

For tests, samples of silumin were taken from washing machines of different brands: “Bosch”, “Samsung” and another sample from a machine of an unknown manufacturer. During the experiments, metals will be immersed in various liquids, and their aggressiveness will be assessed by simple visual inspection.

Experiments were carried out with concentrated solutions to clearly show the processes of interaction of the metal with these reagents. Although the concentrations in the washing machine are much lower, the exposure time is much longer.

1. Food grade citric acid

Citric acid is known as a substance that does an excellent job of removing mineral deposits. It is part of special anti-scale products. Therefore, its effect on washing machine units is quite interesting.

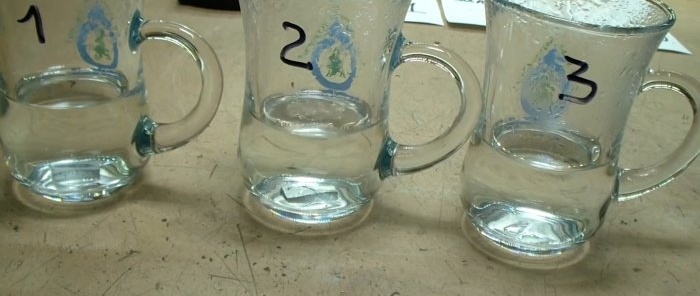

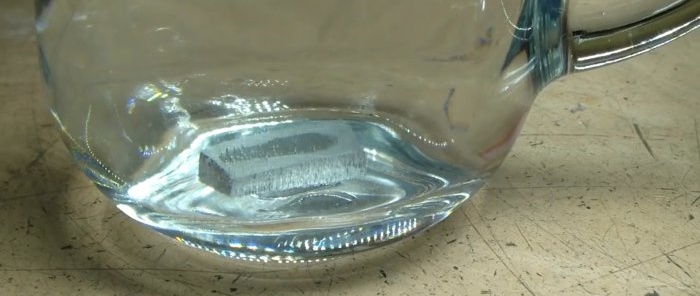

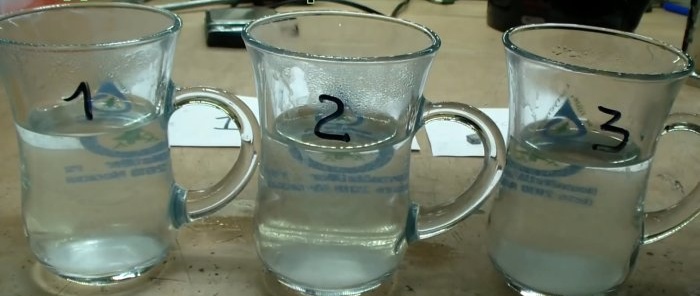

So, dissolve 50 grams of citric acid in 100 milliliters of water. The liquid is then heated to boiling point. A separate vessel is used for each metal sample. Having lowered pieces of silumin into the liquid, we observe a slight release of gas. Moreover, it is most noticeable in the Samsung sample. After 15 minutes of the experiment, we evaluate the condition of the metal pieces. It hasn't changed much. However, the gas release reaction in the solution was extremely weak.

2. Branded product

The second experiment is carried out with a professional cleaning agent for washing machines, recommended by most manufacturers of household appliances. It contains citric and sulfamic acids. The preparation of the solution is similar to the previous experiment.

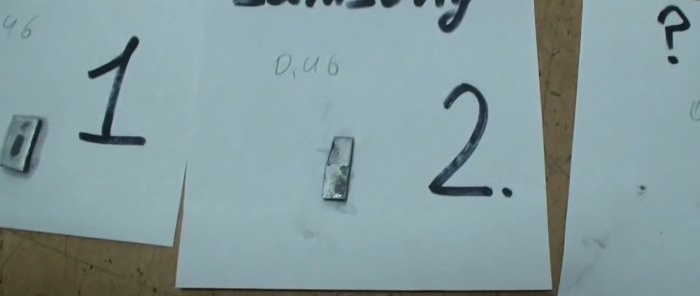

In this experiment, the reaction of gas release from metal samples occurs more actively than in the first. And after 15 minutes, the gas emission did not decrease at all. The reaction is just as active. After removing pieces of metal from the solution, a significant darkening of the samples is clearly visible. The surface lost its shine and became matte. For some reason, the piece that got the most was a piece of silumin from a Bosch machine. The experiment raises doubts about the safety of branded washing machine care products.

3. Whiteness (Bleach)

The metal samples are again cleaned to a shine. A solution was prepared from Whiteness and water in a ratio of 1:3. The samples spent 15 minutes in it. No active reaction was observed. Despite this, the extracted metals lost their luster.

4. Washing powder

And again the silumin pieces are polished to a shine. This time a solution is prepared using popular washing powder. As a result, it turned out cloudy and it was impossible to see any reaction. After 15 minutes of the experiment, the extracted pieces of metal remained just as shiny. This suggests that no reaction occurred in the powder solution.

5. Mole drain cleaner

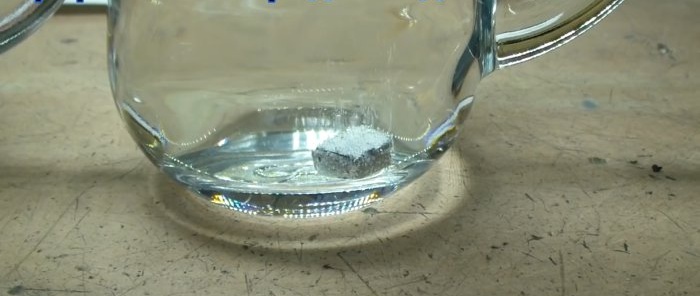

Some housewives use Mole-type products to remove blockages in washing machine drains. Let's prepare a solution with this active drug. The pieces of metal placed in it interact so actively that it seems they will float up from the abundance of gas bubbles released. There's no need to wait 15 minutes here. The samples didn't just darken. A loose layer of reacted metal formed on the surface.

And now the result. What conclusions can be drawn from the experiment. The first and main conclusion is that the metal of the crosspieces of washing machine drums is chemically unstable. Many reagents interact with it.

Of all the solutions, the least active was the solution of Citric acid, which is so heavily criticized on the Internet. I was surprised by the active reaction of silumin with a specialized product for washing machines. And the real killer is the drug “Mole”.

Watch the video

Similar master classes