How to make a heat exchanger and increase the efficiency of a stove for heating a garage with a heating radiator

In order not to bother with the water jacket inside the stove firebox for intermittent heating of the garage, you can get by with a stainless steel heat exchanger wound around the chimney, the ends of which are connected to the heating radiator. Any adult can do this kind of work.

Will need

Materials:

- stove chimney;

- Radiator;

- circulation pump;

- 2 short pieces from a round pipe;

- transition brass fittings from metal to plastic;

- polypropylene fittings and couplings;

- polypropylene tubes, angles and tees;

- coarse filter;

- 4 liter plastic canister;

- fitting and nipple;

- antifreeze 15 liters.

Tools: welding machine and machine for soldering plastic pipes.

Manufacturing process of corrugated stainless tube heat exchanger

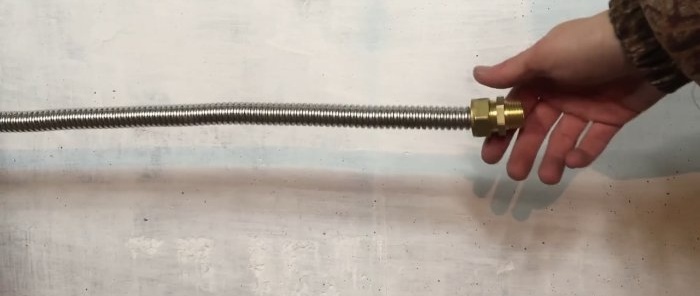

Closer to the base of the chimney we wind a coil of corrugated stainless tube. To prevent the coil from unwinding, at its beginning and end weld short sections from a round pipe or just staples into which we pass a stainless steel tube.

The transition from a corrugated tube to a polypropylene one is carried out using transitional brass fittings, which are tightened by hand and ensure absolute tightness. Next, we use polypropylene fittings to transition from brass fittings to polypropylene pipes.

We first assemble the return line by soldering the end of a polypropylene pipe into a polypropylene fitting using a soldering iron for plastic pipes. We will connect the pipes to the heating radiator using polypropylene couplings.

We install a circulation pump into the return line so that the electrical box is located on top and the arrow is directed towards the stove. We install a coarse filter in front of the pump.

We assemble the supply in the same order, but we cut a tee into it to connect the expansion tank, for which we use a 4-liter plastic canister, in the bottom of which we attach a nipple, and in the lid - a fitting on a nut. We cut the canister closer to the bottom so that it is possible to add coolant to the system if necessary.

We use antifreeze as a coolant, since the garage is planned to be heated from time to time. We fill it through the expansion tank, after opening the tap on the battery. As soon as antifreeze flows from it, the air has been completely removed from the system and it is filled only with coolant. After which, close the tap.

It remains to test the operation of the heat exchanger. To do this, light the stove. We note that the temperature in the garage is -7 degrees Celsius. We reached 0 degrees in 25 minutes. To reach 35 degrees on the radiator I had to wait 1 hour and 25 minutes. At the same time, the temperature of the antifreeze at the outlet of the coil was 42 degrees.

Watch the video

Similar master classes