How to make an original shelf in the bathroom

Very often, when renovating bathrooms and toilets, it becomes necessary to cover old protruding pipes. Sections of leads from risers and heated towel rail lines do not add beauty to the room.

One of the options to add aesthetics and increase functionality is to make shelves. Firstly, the shelves will cover ugly pieces of metal, and secondly, they will serve in the future as a storage place for all kinds of shampoos, air fresheners and detergents.

To make the shelves discussed in this article, the following materials are used:

Tools you will need for work:

First, two sections of bars are secured on both sides of the pipe using dowels and self-tapping screws. The horizontal plane is controlled by the building level. It is necessary to ensure that the bars are firmly secured.

Pieces of plywood are cut to the size of the shelf using a jigsaw. Then they are attracted to the bars with self-tapping screws. The result is a box-shaped structure. Then the shelf needs to be covered with drying oil to improve moisture resistance and dried.

It also happens that the pipe protrudes in one of the corners. In this case, bars are mounted on both sides in a similar way. Pieces of plywood in the shape of triangles are fixed at the top and bottom, and at the end - a rectangle cut to size.

Then the tiles are laid. You need to cut pieces of tile so that they protrude beyond the edge of the plywood by about two centimeters. The tiles are easy to cut with a glass cutter, but it is better to use a tile cutter if you have one.

To install the bottom row of tiles, holes are drilled in the middle of each tile. Then, using a roller cutter, recesses are made for the heads of the screws. Subsequently, the screws will need to be covered with grout.

Pieces of tiles are smeared with liquid nails and secured from below with self-tapping screws. The top row is laid in a similar way, but simpler, without self-tapping screws. In order to cover the outer cut edge of the tile, a decorative plastic corner is used.It is also glued with liquid nails. The glue should dry for about twelve hours.

Then the mosaic elements are made. Since the thickness of the shelves is 70 (mm), the glass is cut a little smaller in size, that is, approximately 60 (mm). Any glass will do; you can even make a mosaic from scraps.

The tiles are cut into small pieces measuring approximately 10x10 (mm). Then liquid nails are applied to the glass and the trimmings are glued to it in random order. It is only necessary to alternate dark and light tones of the tiles to give some completeness to the picture.

After the liquid nails have completely dried, the sheets of the finished mosaic are glued to the ends of the shelves. To ensure that the gaps between the tiles and the mosaic are the same, you can use plastic wedges.

The next day you can begin finishing. Grout for tile joints is diluted with water to the consistency of sour cream and then the joints are filled with a rubber spatula. After about half an hour, excess grout is removed with a soft sponge and water.

One of the options to add aesthetics and increase functionality is to make shelves. Firstly, the shelves will cover ugly pieces of metal, and secondly, they will serve in the future as a storage place for all kinds of shampoos, air fresheners and detergents.

To make the shelves discussed in this article, the following materials are used:

- Pieces of plywood, suitable in size, 10 (mm) thick. You can also use moisture-resistant plasterboard or gypsum fiber sheet.

- Wooden blocks measuring 50x50 (mm). A metal profile of a similar size is also suitable.

- Glass thickness 3 or 4 (mm).

- Cuttings of tiles that were left over when laying the same room.

- Liquid nails, preferably moisture resistant.

- External decorative corners used for tiles.

- Dowels with a diameter of 6 (mm).

- Self-tapping screws measuring 4.2×75 for attaching the bars to the wall.

- Self-tapping screws measuring 3.5×25 for mounting plywood sheets to the bars.

- Drying oil or wood primer.

- Grout for tile joints.

Tools you will need for work:

- Glass cutter

- Drill.

- Tile drill.

- Cone in the form of a hemisphere.

- Hammer.

- Screwdriver.

- Roulette.

- Square.

- Pliers.

- Building level.

- Jigsaw or hacksaw.

- Tile cutter

- Rubber spatula.

Manufacturing process

First, two sections of bars are secured on both sides of the pipe using dowels and self-tapping screws. The horizontal plane is controlled by the building level. It is necessary to ensure that the bars are firmly secured.

Pieces of plywood are cut to the size of the shelf using a jigsaw. Then they are attracted to the bars with self-tapping screws. The result is a box-shaped structure. Then the shelf needs to be covered with drying oil to improve moisture resistance and dried.

It also happens that the pipe protrudes in one of the corners. In this case, bars are mounted on both sides in a similar way. Pieces of plywood in the shape of triangles are fixed at the top and bottom, and at the end - a rectangle cut to size.

Then the tiles are laid. You need to cut pieces of tile so that they protrude beyond the edge of the plywood by about two centimeters. The tiles are easy to cut with a glass cutter, but it is better to use a tile cutter if you have one.

To install the bottom row of tiles, holes are drilled in the middle of each tile. Then, using a roller cutter, recesses are made for the heads of the screws. Subsequently, the screws will need to be covered with grout.

Pieces of tiles are smeared with liquid nails and secured from below with self-tapping screws. The top row is laid in a similar way, but simpler, without self-tapping screws. In order to cover the outer cut edge of the tile, a decorative plastic corner is used.It is also glued with liquid nails. The glue should dry for about twelve hours.

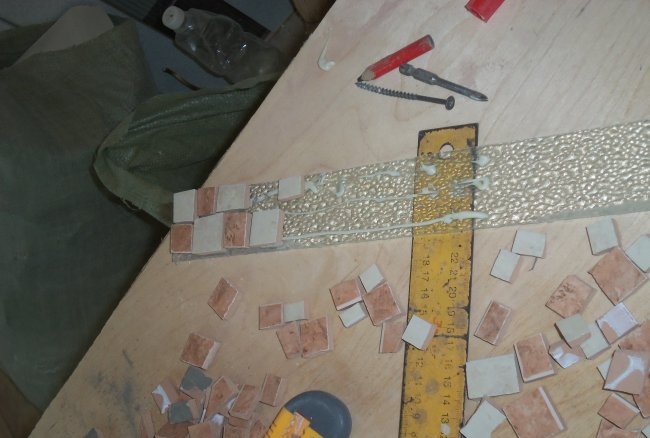

Then the mosaic elements are made. Since the thickness of the shelves is 70 (mm), the glass is cut a little smaller in size, that is, approximately 60 (mm). Any glass will do; you can even make a mosaic from scraps.

The tiles are cut into small pieces measuring approximately 10x10 (mm). Then liquid nails are applied to the glass and the trimmings are glued to it in random order. It is only necessary to alternate dark and light tones of the tiles to give some completeness to the picture.

After the liquid nails have completely dried, the sheets of the finished mosaic are glued to the ends of the shelves. To ensure that the gaps between the tiles and the mosaic are the same, you can use plastic wedges.

The next day you can begin finishing. Grout for tile joints is diluted with water to the consistency of sour cream and then the joints are filled with a rubber spatula. After about half an hour, excess grout is removed with a soft sponge and water.

Similar master classes

Particularly interesting

Comments (0)