Copper deposition on non-metallic objects

Good afternoon In this article we will look at the process of electrochemical deposition of copper on conductive surfaces, and also try to coat a walnut with a copper layer.

So, for the experiment we will need:

Pour 100 grams of vitriol into a container, pour half a liter of water and add 70 grams of acid electrolyte.

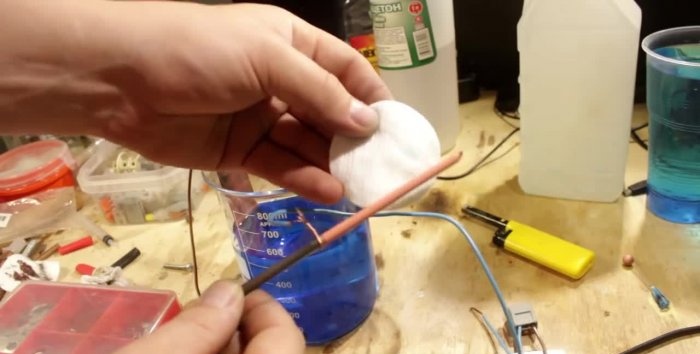

Mix and filter through a funnel and cotton pad.

Install and secure the copper electrode:

The plus power supply from charging will be connected to it. We make three taps from the minus: we solder a 1 kOhm resistor to the first, and a 220 Ohm resistor to the second.

In this way we can conveniently regulate the supplied current.

When you turn on the charger, a chemical process called electrodeposition will begin.Under the influence of electric current, copper atoms on the positive contact are oxidized and dissolved in the electrolyte, then deposited on the negative. The power source current is selected at the rate of 1 Ampere per 100 cm² of surface to be coated.

First, let's coat a regular iron nail with copper. Coverage area – 10 cm².

Clean with sandpaper:

We connect it to the power supply negative through a 1 kOhm resistor, and lower it into the solution. After 30 seconds, take it out and wipe it with a cotton pad. As a result, the layer turned out to be quite loose and erased.

Now let's try to create a truly durable coating. To do this, we clean the nail and connect it through a 220 Ohm resistor, lower it into the solution for 10-15 seconds. Then we change the resistance to 1 kOhm and leave it for half an hour. Here's what happened:

This time the coating turned out to be durable and left no marks on the disc at all.

After sanding, a small amount of copper still covered the nail.

Let's try to coat a lead cake with copper. If you connect it through a resistance, even after a few minutes the result will be negligible.

But as soon as you connect it directly, within a minute the cake will be completely covered with copper.

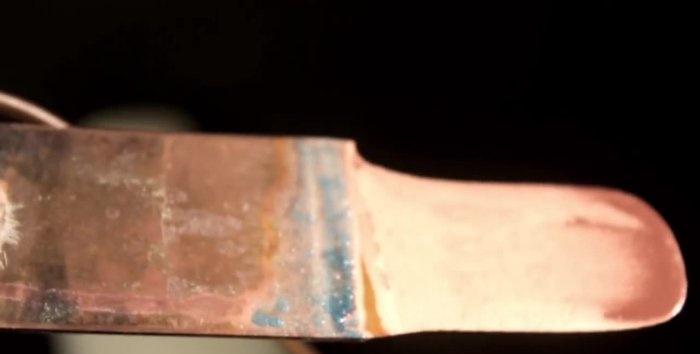

If the coverage area is too small, then severe darkening can be observed:

This phenomenon is called carbon deposits and is due to the fact that too much current flows across a given surface.

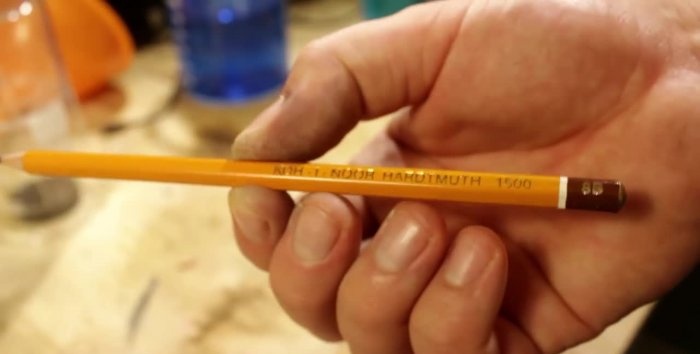

We figured out the metals, but what about dielectrics, they don’t conduct current and the reaction simply won’t start. But there is a way out: we need to cover our object with conductive material. Graphite, from which leads for simple pencils are made, is excellent for the latter.

Take the softest pencil.Soft pencils are marked with the letter “B”, and the number at the beginning indicates the degree of softness. A hard pencil works better with fine details. Let's color our nut.

Applying graphite using this method is a very tedious task, so construction stores sell a special graphite spray. He will cope with this task much faster.

After painting, we manually make a hole for the “twig” using a drill. Pour super glue into it, seal it with thick copper wire and fill it with graphite powder left over after decorating the nut.

We connect the minus power to the wire through a 1 kOhm resistor. At this stage, you should not apply a large current, otherwise the copper layer will turn out loose, which is not good. After half an hour, the nut is slightly coated with copper and the resistance can be reduced to 220 Ohms.

After some time, the growth of copper will slow down and the resistance will have to be reduced further

To do this, we will use a block of wood and a nichrome thread threaded like a snake onto screws along its edges.

We set the resistance to 70 ohms.

When the copper completely covers the nut, set the value of the improvised resistor to 5 Ohms and leave the nut for another five hours for a thick and uniform coating.

During this time, the copper electrode was greatly depleted.

All this copper settled on our nut, creating a rough layer.

At the end of the process, the nut noticeably gained weight.

To give the copper surface a nice shine, we will cover it with a patina and then polish it.

For this we need:

Pour a little ammonia into a glass and crumble a little sulfur.Place the nut there, as shown in the photo.

The glass must be covered with something, because during the reaction, hydrogen sulfide is released - a gas with a pungent odor. After 20 minutes, the nut has darkened greatly; we take it out of the glass. We bite off the “twig” and bend the end into a loop with pliers.

All that remains is to polish the nut with wet, rubbed sandpaper.

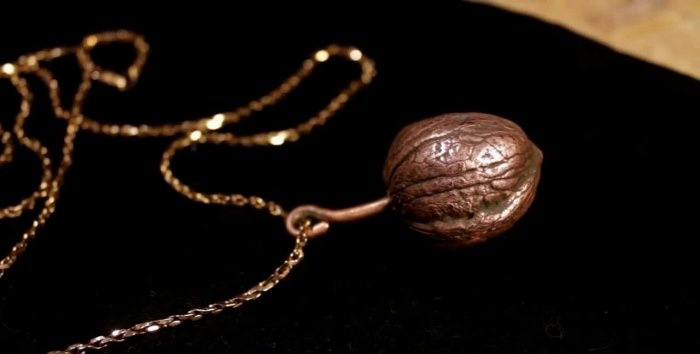

We thread the chain through the loop, and that’s it – the product is ready!

And that's all for me. Happy experiments everyone!

Will need

So, for the experiment we will need:

- A non-metallic container - a beaker or a regular tray, where the deposition process will take place;

- Water, preferably purified;

- Copper sulfate (sold in garden stores);

- Acid electrolyte for batteries (in car shops);

- Charger 5 Volt, 0.3 Ampere;

- 1 kOhm and 220 Ohm resistors to limit the supplied current;

- Copper electrode.

Trying it on metal

Pour 100 grams of vitriol into a container, pour half a liter of water and add 70 grams of acid electrolyte.

Mix and filter through a funnel and cotton pad.

Install and secure the copper electrode:

The plus power supply from charging will be connected to it. We make three taps from the minus: we solder a 1 kOhm resistor to the first, and a 220 Ohm resistor to the second.

In this way we can conveniently regulate the supplied current.

When you turn on the charger, a chemical process called electrodeposition will begin.Under the influence of electric current, copper atoms on the positive contact are oxidized and dissolved in the electrolyte, then deposited on the negative. The power source current is selected at the rate of 1 Ampere per 100 cm² of surface to be coated.

Experience

First, let's coat a regular iron nail with copper. Coverage area – 10 cm².

Clean with sandpaper:

We connect it to the power supply negative through a 1 kOhm resistor, and lower it into the solution. After 30 seconds, take it out and wipe it with a cotton pad. As a result, the layer turned out to be quite loose and erased.

Now let's try to create a truly durable coating. To do this, we clean the nail and connect it through a 220 Ohm resistor, lower it into the solution for 10-15 seconds. Then we change the resistance to 1 kOhm and leave it for half an hour. Here's what happened:

This time the coating turned out to be durable and left no marks on the disc at all.

After sanding, a small amount of copper still covered the nail.

Let's try to coat a lead cake with copper. If you connect it through a resistance, even after a few minutes the result will be negligible.

But as soon as you connect it directly, within a minute the cake will be completely covered with copper.

If the coverage area is too small, then severe darkening can be observed:

This phenomenon is called carbon deposits and is due to the fact that too much current flows across a given surface.

Coating a copper nut

We figured out the metals, but what about dielectrics, they don’t conduct current and the reaction simply won’t start. But there is a way out: we need to cover our object with conductive material. Graphite, from which leads for simple pencils are made, is excellent for the latter.

Take the softest pencil.Soft pencils are marked with the letter “B”, and the number at the beginning indicates the degree of softness. A hard pencil works better with fine details. Let's color our nut.

Applying graphite using this method is a very tedious task, so construction stores sell a special graphite spray. He will cope with this task much faster.

After painting, we manually make a hole for the “twig” using a drill. Pour super glue into it, seal it with thick copper wire and fill it with graphite powder left over after decorating the nut.

We connect the minus power to the wire through a 1 kOhm resistor. At this stage, you should not apply a large current, otherwise the copper layer will turn out loose, which is not good. After half an hour, the nut is slightly coated with copper and the resistance can be reduced to 220 Ohms.

After some time, the growth of copper will slow down and the resistance will have to be reduced further

To do this, we will use a block of wood and a nichrome thread threaded like a snake onto screws along its edges.

We set the resistance to 70 ohms.

When the copper completely covers the nut, set the value of the improvised resistor to 5 Ohms and leave the nut for another five hours for a thick and uniform coating.

During this time, the copper electrode was greatly depleted.

All this copper settled on our nut, creating a rough layer.

At the end of the process, the nut noticeably gained weight.

Treatment

To give the copper surface a nice shine, we will cover it with a patina and then polish it.

For this we need:

- Ammonia, also known as ammonia solution;

- Sulfur bomb (can be found in garden stores);

- Chemical or disposable glass;

- Fine-grit sandpaper.

Pour a little ammonia into a glass and crumble a little sulfur.Place the nut there, as shown in the photo.

The glass must be covered with something, because during the reaction, hydrogen sulfide is released - a gas with a pungent odor. After 20 minutes, the nut has darkened greatly; we take it out of the glass. We bite off the “twig” and bend the end into a loop with pliers.

All that remains is to polish the nut with wet, rubbed sandpaper.

We thread the chain through the loop, and that’s it – the product is ready!

And that's all for me. Happy experiments everyone!

Watch the video

Similar master classes

Particularly interesting

Comments (1)