A simple stand for an angle grinder made from a bicycle

If you have an angle grinder, you can saw, grind and cut many materials - wood, metal, stone, tiles, etc. But what to do when you need to cut long strands into pieces and ensure precision trimming. This requires complex and expensive machines.

It is very difficult to cut tiles or bricks with precision cutting if you hold the grinder only with your hands. Manual cutting of thin and viscous materials with the slightest deviation of the equipment from the cutting direction can cause jamming and breakage of the disc.

In such cases, in order to avoid purchasing a separate machine, it is enough to make a device that will rigidly and accurately hold the angle grinder in a given position.

In addition to the grinder, which we can use to make individual parts of our homemade product, we will need:

From equipment and tools, along with an angle grinder, we will need:

The old bike is washed, wiped and put in order. We remove the wheels - we won't need them. Remove the steering wheel with the steering column and stem.

Lubricate with oil and unscrew the nut to hold the bearing and remove the fork from the frame crown.

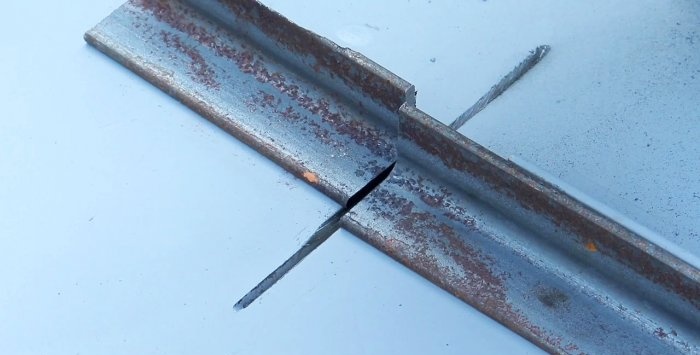

We cut off the “horns” and fork legs of the break bosses from the steering wheel.

We cut out the steering tube with part of the horizontal and inclined tube from the frame.

We put these knots in order with a grinder, sandpaper and cloth napkins.

We cut off part of the shelf from the corner, cleaning it with a grinding wheel and making the necessary markings. In the cut strip we mark the centers of two holes, drill holes and round one side.

We weld the plate to the base of the feathers, resting its flat end against one feather and placing it on the second. We turn the fork over and weld the plate to it on the other side.

We cut off the required piece from the sheet of metal according to the markings and process the ends. We make 4 equal blanks from a profile pipe and weld them at the corners of the metal sheet according to the markings.

We strengthen the legs in pairs on the narrow side of the sheet, welding a reinforcement bridge between them closer to the supporting heels.

We turn the structure 180 degrees and get a table on four legs with a metal tabletop.

We weld the steering tube to the tabletop with part of the horizontal and inclined frame tube in the center of the narrow side closer to the end.

We move the steering column flush in the steering stem holder and secure it in this position with a nut. We clean the fork rod and install a new upper bearing, having previously lubricated it. We insert the fork rod with the bearing into the frame crown until it stops.We also install a new lubricated bearing on the protruding side of the rod and tighten it with a flat washer with a thread and a control nut. We insert the steering column with the steering stem into the holes of the nuts, in the holder of which the central part of the steering wheel is secured, offset to one side. Tighten all the nuts until they stop.

In two equal-length corners of equal length, we drill two holes on one shelf and corresponding holes in the metal of the tabletop. We secure them with bolts and nuts so that they provide cuts at 90 and 45 degrees. We cut a through groove of the required length in the tabletop directly under the disk of the grinder mounted in the stand.

We weld a nut to the end of the table top from the side of the complex assembly.

Then we weld the stud with a screwed nut on top of the fork crown, placing the free end in its center.

We cover the entire structure with nitro paint from an aerosol can.

We put a soft handle (grip) on the free end of the central part of the steering wheel.

We attach a spring to the nut on the tabletop and to the end of the stud and screw a second nut onto the end of the stud so that the spring does not fly off.

We pass the plug with the angle grinder cord through the clamp, which we tighten in the center of the angle grinder body.

We secure the angle grinder with two bolts to the threaded hole in the body and to the clamp nut through a plate with holes welded to the fork legs.

Now you can, by moving the lever by the grip, easily change the position of the angle grinder relative to the work table, after which, thanks to the spring, the angle grinder returns to its original position.

We apply voltage to the tool and test it in action. Using a guide corner directly attached to the table, we cut long strands (pipes, angles, channels, etc.).

We apply a square to the cut and make sure that it is made exactly at 90 degrees.

If a long piece needs to be cut at an angle of 45 degrees, use the second corner as a guide.

By folding them along the cutting line and applying a protractor to the inner corner, we make sure that it is exactly 90 degrees.

It is very difficult to cut tiles or bricks with precision cutting if you hold the grinder only with your hands. Manual cutting of thin and viscous materials with the slightest deviation of the equipment from the cutting direction can cause jamming and breakage of the disc.

In such cases, in order to avoid purchasing a separate machine, it is enough to make a device that will rigidly and accurately hold the angle grinder in a given position.

Will need

In addition to the grinder, which we can use to make individual parts of our homemade product, we will need:

- separate parts from an old bicycle;

- steel corner;

- profile pipe;

- a metal sheet;

- bolts, nuts and stud;

- tension spring;

- a can of spray paint, etc.

From equipment and tools, along with an angle grinder, we will need:

- welding machine;

- drill or drilling machine;

- wrenches and screwdriver;

- marker and measuring devices, etc.

Manufacturing procedure

The old bike is washed, wiped and put in order. We remove the wheels - we won't need them. Remove the steering wheel with the steering column and stem.

Lubricate with oil and unscrew the nut to hold the bearing and remove the fork from the frame crown.

We cut off the “horns” and fork legs of the break bosses from the steering wheel.

We cut out the steering tube with part of the horizontal and inclined tube from the frame.

We put these knots in order with a grinder, sandpaper and cloth napkins.

We cut off part of the shelf from the corner, cleaning it with a grinding wheel and making the necessary markings. In the cut strip we mark the centers of two holes, drill holes and round one side.

We weld the plate to the base of the feathers, resting its flat end against one feather and placing it on the second. We turn the fork over and weld the plate to it on the other side.

We cut off the required piece from the sheet of metal according to the markings and process the ends. We make 4 equal blanks from a profile pipe and weld them at the corners of the metal sheet according to the markings.

We strengthen the legs in pairs on the narrow side of the sheet, welding a reinforcement bridge between them closer to the supporting heels.

We turn the structure 180 degrees and get a table on four legs with a metal tabletop.

We weld the steering tube to the tabletop with part of the horizontal and inclined frame tube in the center of the narrow side closer to the end.

We move the steering column flush in the steering stem holder and secure it in this position with a nut. We clean the fork rod and install a new upper bearing, having previously lubricated it. We insert the fork rod with the bearing into the frame crown until it stops.We also install a new lubricated bearing on the protruding side of the rod and tighten it with a flat washer with a thread and a control nut. We insert the steering column with the steering stem into the holes of the nuts, in the holder of which the central part of the steering wheel is secured, offset to one side. Tighten all the nuts until they stop.

In two equal-length corners of equal length, we drill two holes on one shelf and corresponding holes in the metal of the tabletop. We secure them with bolts and nuts so that they provide cuts at 90 and 45 degrees. We cut a through groove of the required length in the tabletop directly under the disk of the grinder mounted in the stand.

We weld a nut to the end of the table top from the side of the complex assembly.

Then we weld the stud with a screwed nut on top of the fork crown, placing the free end in its center.

We cover the entire structure with nitro paint from an aerosol can.

We put a soft handle (grip) on the free end of the central part of the steering wheel.

We attach a spring to the nut on the tabletop and to the end of the stud and screw a second nut onto the end of the stud so that the spring does not fly off.

We pass the plug with the angle grinder cord through the clamp, which we tighten in the center of the angle grinder body.

We secure the angle grinder with two bolts to the threaded hole in the body and to the clamp nut through a plate with holes welded to the fork legs.

Testing an angle grinder with a stand

Now you can, by moving the lever by the grip, easily change the position of the angle grinder relative to the work table, after which, thanks to the spring, the angle grinder returns to its original position.

We apply voltage to the tool and test it in action. Using a guide corner directly attached to the table, we cut long strands (pipes, angles, channels, etc.).

We apply a square to the cut and make sure that it is made exactly at 90 degrees.

If a long piece needs to be cut at an angle of 45 degrees, use the second corner as a guide.

By folding them along the cutting line and applying a protractor to the inner corner, we make sure that it is exactly 90 degrees.

Watch the video

Similar master classes

A stand for an angle grinder made from the handle of a children's bicycle. Extremely

A simple stand for an angle grinder

Stand for an angle grinder or pendulum saw from an angle grinder

How to increase the functionality of an angle grinder with removable equipment

Bike rack

How to install a drill chuck on an angle grinder and why it can

Particularly interesting

Comments (0)