A stand for an angle grinder made from the handle of a children's bicycle. Extremely useful homemade product

Good crafts can be made from literally anything. An example of this is a cross-cutting machine for a grinder made from a parent’s handle from a child’s bicycle. This is a removable part, the need for which disappears when the child begins to ride independently, so it can be used on the machine without remorse.

The parent handle is a telescopic structure in which the diameter of the internal and external tubes is selected in such a way that there is no play between them. Both parts will be used in the homemade product.

The base for the bike mount is cut off from the lower pipes. Only the handles are cut off from the top ones to create a U-shaped part. You also need to remove the membrane between the upper tubes.

Literally 40 mm is cut off from the U-shaped steel profile. This piece will be used to fix the rotating mechanism of the angle grinder to the telescopic part of the machine.

Next, you need to bend a bracket from a steel strip, which will be attached to a piece of U-shaped profile.

The parts are joined and side holes are drilled into them, which will allow them to be connected in the future by a common axis.

A piece is cut from the steel strip to fit the length of the existing grinder. It will be used as a basis for fixing it. The trim is screwed to the previously bent bracket. At the same time, it should extend slightly beyond its limits in the front part in order to make a hole for attaching the angle grinder through the mounting socket for its handle

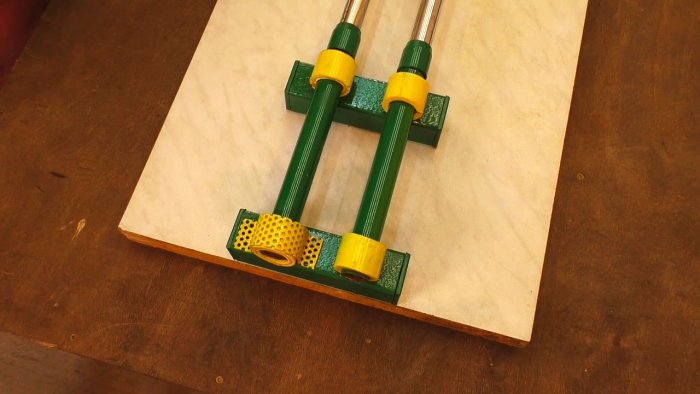

To fix the telescopic part of the machine to the tabletop, you need to prepare 2 pieces of profile square pipe. You will also need 4 spacers made of polypropylene pipe, cut lengthwise. For direct fixation, you need to make 4 clamps from a sieve or sheet metal.

We paint all the parts.

Assembling the machine must begin by attaching the scraps of the profile square to the table top. Telescopic guides are already screwed to them through polypropylene tubes using clamps.

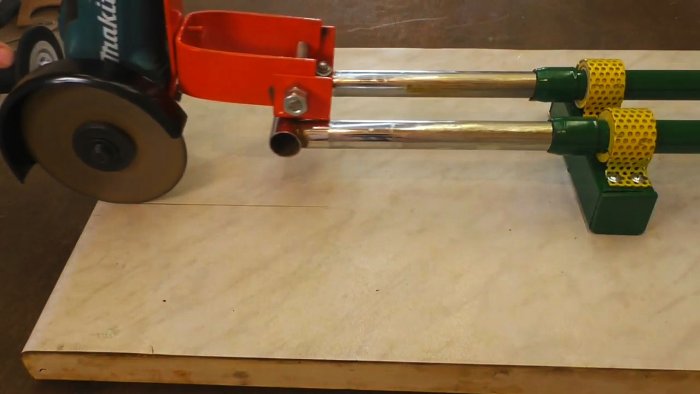

Next, the rotating mechanism is secured. To do this, a U-shaped profile is screwed to the telescopic fork. A curved bracket with a base for an angle grinder is attached to it using a pin.

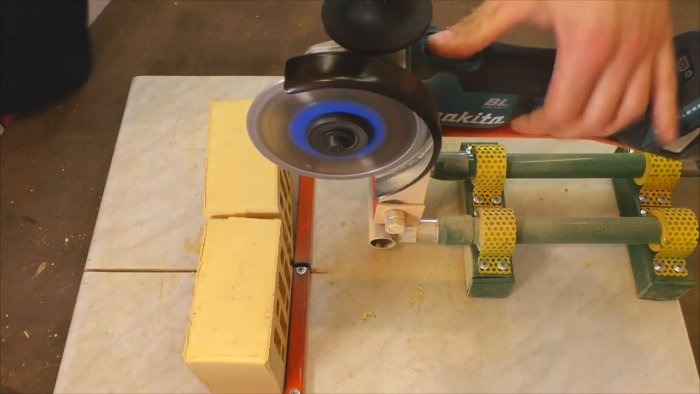

The angle grinder itself must be secured with a bolt, screwing it through the strip of the rotating mechanism into the lower hole to fix its handle.

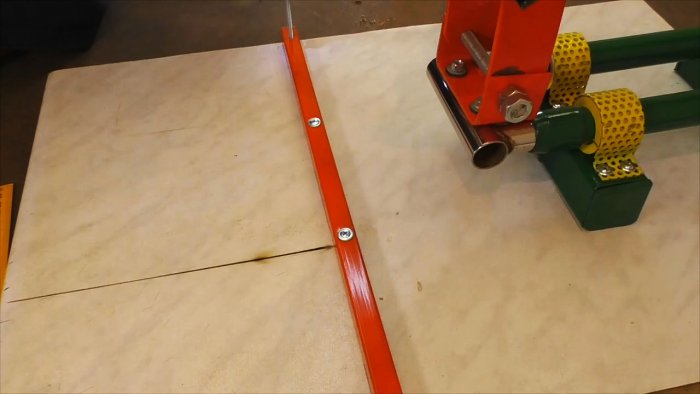

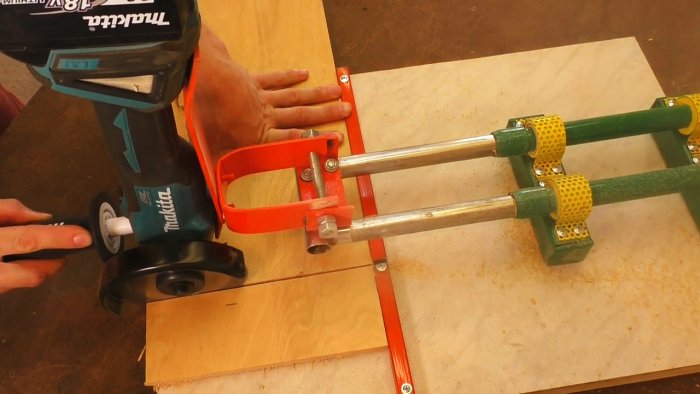

With the grinder in place, you need to make a cut along the tabletop. A transverse stop is fixed along it at an angle of 90 degrees, along which the trim will be made.

The machine is assembled without welding using a minimal set of tools.The grinder is quickly placed and removed on it, without compromising its integrity. The device works without backlash and is very accurate. Its maintenance comes down only to updating the lubricant between the pipes of the telescopic mechanism.

Basic materials:

- parent bicycle handle;

- steel strip 40 mm;

- steel U-shaped profile 30x50 mm or more;

- profile square pipe 40x40mm;

- polypropylene pipe 32 mm;

- sieve or tin;

- thin profile pipe or any small corner.

Assembling a cross-cutting machine

The parent handle is a telescopic structure in which the diameter of the internal and external tubes is selected in such a way that there is no play between them. Both parts will be used in the homemade product.

The base for the bike mount is cut off from the lower pipes. Only the handles are cut off from the top ones to create a U-shaped part. You also need to remove the membrane between the upper tubes.

Literally 40 mm is cut off from the U-shaped steel profile. This piece will be used to fix the rotating mechanism of the angle grinder to the telescopic part of the machine.

Next, you need to bend a bracket from a steel strip, which will be attached to a piece of U-shaped profile.

The parts are joined and side holes are drilled into them, which will allow them to be connected in the future by a common axis.

A piece is cut from the steel strip to fit the length of the existing grinder. It will be used as a basis for fixing it. The trim is screwed to the previously bent bracket. At the same time, it should extend slightly beyond its limits in the front part in order to make a hole for attaching the angle grinder through the mounting socket for its handle

To fix the telescopic part of the machine to the tabletop, you need to prepare 2 pieces of profile square pipe. You will also need 4 spacers made of polypropylene pipe, cut lengthwise. For direct fixation, you need to make 4 clamps from a sieve or sheet metal.

We paint all the parts.

Assembling the machine must begin by attaching the scraps of the profile square to the table top. Telescopic guides are already screwed to them through polypropylene tubes using clamps.

Next, the rotating mechanism is secured. To do this, a U-shaped profile is screwed to the telescopic fork. A curved bracket with a base for an angle grinder is attached to it using a pin.

The angle grinder itself must be secured with a bolt, screwing it through the strip of the rotating mechanism into the lower hole to fix its handle.

With the grinder in place, you need to make a cut along the tabletop. A transverse stop is fixed along it at an angle of 90 degrees, along which the trim will be made.

The machine is assembled without welding using a minimal set of tools.The grinder is quickly placed and removed on it, without compromising its integrity. The device works without backlash and is very accurate. Its maintenance comes down only to updating the lubricant between the pipes of the telescopic mechanism.

Watch the video

Similar master classes

Particularly interesting

Comments (2)