Do-it-yourself electric hacksaw from a grinder

The grinder is an excellent tool for improvement. Its design is well suited for connecting various accessories that completely change the functionality of an angle grinder. Many of these attachments can be made with your own hands. An example of this is a removable wood reciprocating saw powered by a grinder drive.

Unscrew the handle of the hacksaw.

In order for the saw to make translational movements, it is necessary to make an eccentric. To do this, a washer, bearing, washer and M14 nut are put on the angle grinder spindle. To shift the center of the structure, it is necessary to insert a piece of M8 bolt into the gap between the spindle and the bearing. It needs to be cut to the height of the bearing. The resulting structure is tightly clamped with a nut, due to which the eccentric will rotate without friction on the spindle thread.

To attach the saw, a similar design will be used as on the standard grinder guard.Take a piece of pipe with a length equal to the distance between the beginning of the gearbox and the middle of the eccentric bearing. Next, it is partially cut into 2 rings. The cut should be more than half. The cut line runs opposite the edge of the seat for attaching the casing.

Next you need to cut the bottom ring.

An M6 nut is welded to the edges of the cut. With their help, the ring will tighten like a clamp when tightening the bolt.

A hole is drilled in the hacksaw blade 1 mm larger than the outer diameter of the bearing. It is slightly bored at the top and bottom. Given the quality of the hacksaw steel, the work will take time.

2 identical rectangular plates of arbitrary size are cut from sheet steel. A 40 mm hole is drilled in their center.

One plate is welded to a clamp tube.

A 6 mm hole is drilled in the corners of both rectangles. They should be opposite each other.

Holes are marked on the hacksaw blade, as on plates. They are drilled and then bored with a file to allow the blade to move. You need to sharpen in both directions in a horizontal direction from the centers of the holes.

For aesthetics, you can paint it with aerosol paint from a can.

To use the attachment, you need to lubricate the contact surfaces of the blade and pressure plates with grease.

The parts are tightened together with bolts and nuts. You need to pull it loosely. Lock nuts are placed on top to prevent the blade from being unscrewed or pinched.

An eccentric is assembled on the grinder, and the attachment is placed instead of the protective casing. All reciprocating saws can be used. After use, the equipment can be removed and the angle grinder can be used as usual.

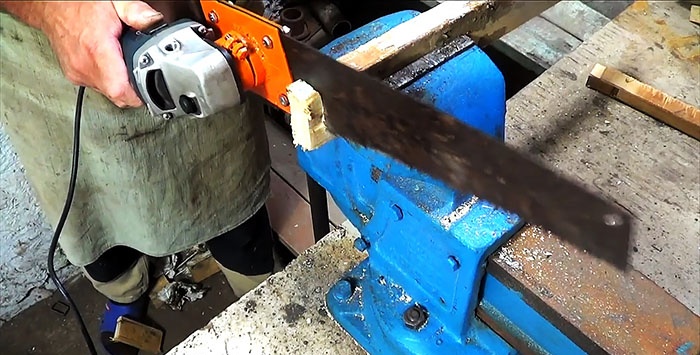

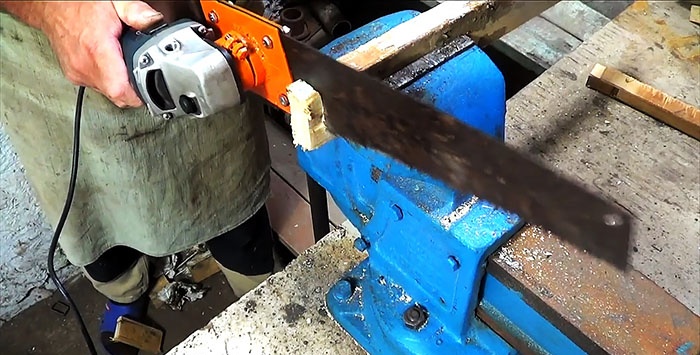

And we start sawing work.

Materials:

- wood hacksaw;

- bearing with an internal diameter of 22 mm;

- 2 enlarged washers M14;

- nut M14;

- M8 bolt;

- steel pipe d 40 mm;

- 5 M6 bolts;

- 11 M6 nuts;

- sheet steel 2 mm.

Making the nozzle

Unscrew the handle of the hacksaw.

In order for the saw to make translational movements, it is necessary to make an eccentric. To do this, a washer, bearing, washer and M14 nut are put on the angle grinder spindle. To shift the center of the structure, it is necessary to insert a piece of M8 bolt into the gap between the spindle and the bearing. It needs to be cut to the height of the bearing. The resulting structure is tightly clamped with a nut, due to which the eccentric will rotate without friction on the spindle thread.

To attach the saw, a similar design will be used as on the standard grinder guard.Take a piece of pipe with a length equal to the distance between the beginning of the gearbox and the middle of the eccentric bearing. Next, it is partially cut into 2 rings. The cut should be more than half. The cut line runs opposite the edge of the seat for attaching the casing.

Next you need to cut the bottom ring.

An M6 nut is welded to the edges of the cut. With their help, the ring will tighten like a clamp when tightening the bolt.

A hole is drilled in the hacksaw blade 1 mm larger than the outer diameter of the bearing. It is slightly bored at the top and bottom. Given the quality of the hacksaw steel, the work will take time.

2 identical rectangular plates of arbitrary size are cut from sheet steel. A 40 mm hole is drilled in their center.

One plate is welded to a clamp tube.

A 6 mm hole is drilled in the corners of both rectangles. They should be opposite each other.

Holes are marked on the hacksaw blade, as on plates. They are drilled and then bored with a file to allow the blade to move. You need to sharpen in both directions in a horizontal direction from the centers of the holes.

For aesthetics, you can paint it with aerosol paint from a can.

To use the attachment, you need to lubricate the contact surfaces of the blade and pressure plates with grease.

The parts are tightened together with bolts and nuts. You need to pull it loosely. Lock nuts are placed on top to prevent the blade from being unscrewed or pinched.

An eccentric is assembled on the grinder, and the attachment is placed instead of the protective casing. All reciprocating saws can be used. After use, the equipment can be removed and the angle grinder can be used as usual.

And we start sawing work.

Watch the video

Similar master classes

Particularly interesting

Comments (4)