Homemade high-performance pump for pumping water driven by an angle grinder

Having a home pool or garden pond, periodically there is a need to drain water from them, which requires a high-performance pump. If you wish and have time, you can do it yourself. Moreover, the homemade pump pumps water very quickly, since a grinder is used to drive its impeller. At the same time, it can still be used for its main purpose.

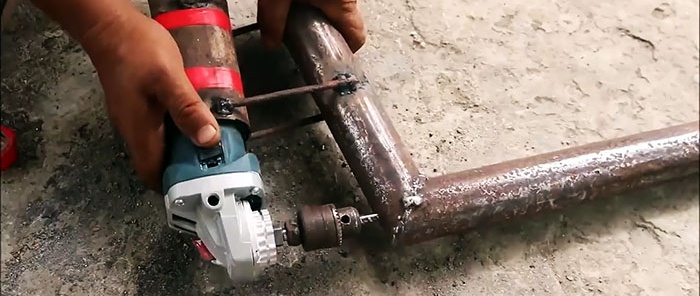

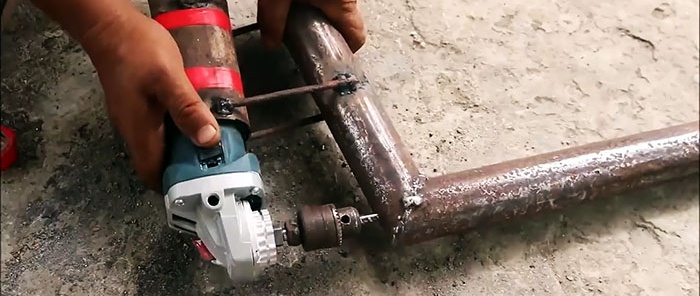

To organize the drive for the pump, you need to remove the handle and protection from the angle grinder, then install a drill chuck on its shaft. An M14 nut is welded to the latter, so it simply screws on.

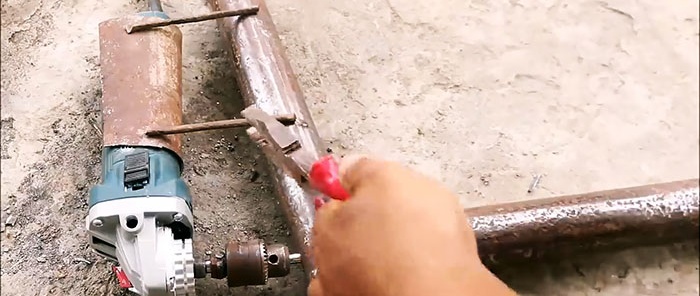

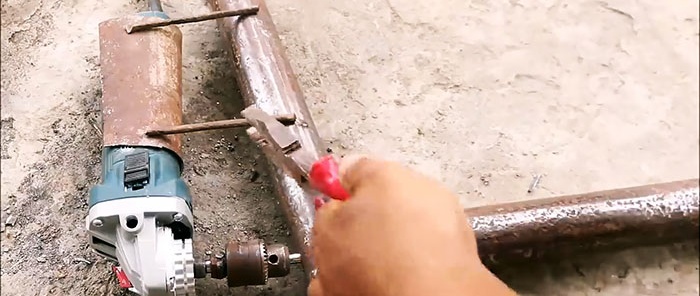

Next, from two pieces of pipe cut at an angle of 45 degrees, you need to weld an L-shaped structure.

The length of one cutting should be approximately 50 cm, and the second is selected individually depending on the required depth of water intake.Before welding the parts, a hole 1 mm thicker than the diameter of the available fittings is drilled on the bevel of a half-meter pipe.

A piece of fittings 10 cm longer than the water intake tube is used as the pump shaft. An impeller, bent from a previously leveled piece of the same pipe, is welded to it closer to the edge.

The shaft with the impeller is inserted into the water intake and passed through a drilled hole. In this case, the ribs on the reinforcement in the area of the hole need to be ground. Next, a strip is cut out of the leveled plate, in which a hole is made for the shaft. The resulting plate is welded to the end of the intake tube. The reinforcement in the area of contact with it must also be machined away from the ribs.

Another piece of pipe needs to be cut lengthwise. After this, it is partially unbent to obtain a casing to accommodate the body of the angle grinder.

After this, with the casing on, you need to clamp the impeller shaft in the grinder chuck. Next, the casing is welded to the spout pipe using 4 pieces of fittings. To keep the angle grinder in place, it must be secured with clamps or electrical tape. All pumps can be used for their intended purpose.

As you can see in the example, the drain tube is short, so water gets onto the power cord of the angle grinder. If you initially make it 50 cm, then there will be no such problem. The resulting pump pumps water very quickly, but still it is not designed to lift the column to a great height. It can be used to drain a pool or pond without having to pump water through a long hose into a tank.

This instruction is intended for informational purposes only, but not for repetition, since power tools and water are a very dangerous combination.

Materials:

- steel pipe d50 mm;

- steel reinforcement 6-8 mm;

- drill chuck for drill;

- nut M14.

Making a pump

To organize the drive for the pump, you need to remove the handle and protection from the angle grinder, then install a drill chuck on its shaft. An M14 nut is welded to the latter, so it simply screws on.

Next, from two pieces of pipe cut at an angle of 45 degrees, you need to weld an L-shaped structure.

The length of one cutting should be approximately 50 cm, and the second is selected individually depending on the required depth of water intake.Before welding the parts, a hole 1 mm thicker than the diameter of the available fittings is drilled on the bevel of a half-meter pipe.

A piece of fittings 10 cm longer than the water intake tube is used as the pump shaft. An impeller, bent from a previously leveled piece of the same pipe, is welded to it closer to the edge.

The shaft with the impeller is inserted into the water intake and passed through a drilled hole. In this case, the ribs on the reinforcement in the area of the hole need to be ground. Next, a strip is cut out of the leveled plate, in which a hole is made for the shaft. The resulting plate is welded to the end of the intake tube. The reinforcement in the area of contact with it must also be machined away from the ribs.

Another piece of pipe needs to be cut lengthwise. After this, it is partially unbent to obtain a casing to accommodate the body of the angle grinder.

After this, with the casing on, you need to clamp the impeller shaft in the grinder chuck. Next, the casing is welded to the spout pipe using 4 pieces of fittings. To keep the angle grinder in place, it must be secured with clamps or electrical tape. All pumps can be used for their intended purpose.

As you can see in the example, the drain tube is short, so water gets onto the power cord of the angle grinder. If you initially make it 50 cm, then there will be no such problem. The resulting pump pumps water very quickly, but still it is not designed to lift the column to a great height. It can be used to drain a pool or pond without having to pump water through a long hose into a tank.

This instruction is intended for informational purposes only, but not for repetition, since power tools and water are a very dangerous combination.

Watch the video

Similar master classes

Particularly interesting

Comments (3)