How to make a cool lamp from PVC pipe

Creative ideas often arise unexpectedly and seemingly out of nowhere. But their material implementation gives such dividends that the costs of their implementation actually seem meager. Today we will try to make a decorative lamp from a PVC pipe that looks inconspicuous at first glance, which will not leave anyone indifferent.

To materialize this creative idea into a beautiful product, we need to have:

You should also get:

On the pipe blank we mark a section 24 cm long. Using a sheet of paper, we make circular lines on the side surface of the plastic pipe according to the markings.

Using a mini-grinder, using the circular markings, we cut off the excess from the plastic pipe blank.

We place a wooden box on the desktop that will serve as a template. Let’s check its cross-sectional dimensions once again: they should be 12x6 cm, which is acceptable as a template for a PVC pipe with a diameter of 10 cm.

We twist a sheet of paper into a bundle and set it on fire at one end from an external fire source (lighter, matches, etc.).

The thermal energy from a burning sheet of paper will be quite enough to soften the material of the plastic pipe, mainly on one side. This method is for those who do not have a hair dryer.

Then quickly, before the plastic has cooled, we insert a wooden template inside the pipe and form a rectangular one from the round section along the entire length, pushing the wooden box along the pipe until it appears on the other side of the pipe blank.

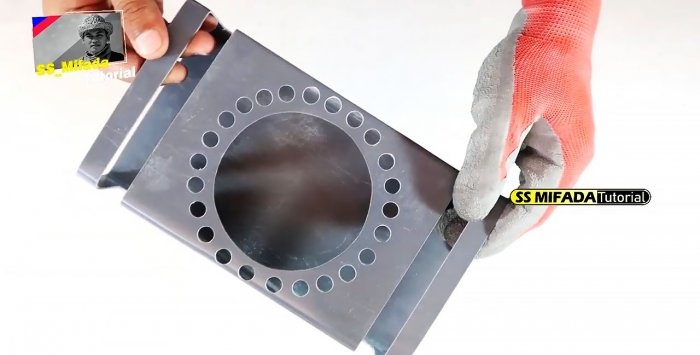

We leave the template in the pipe until the plastic cools down and takes on a stable rectangular cross-sectional shape, after which it can be removed from there. After making sure that the shape of the rectangular plastic element is without flaws, we process the ends with a mini-drill, removing burrs and rounding the edges. We use the round ring left over from cutting a plastic pipe as a template for reproducing a circle in the center of the wide side of a rectangular plastic element.

Using a hand router, we cut out a circle according to the applied markings and clean the edges of the resulting hole by changing the nozzle.

At a certain and equal distance from the edge of the hole, we mark 23 points, evenly spaced around the circumference of a large circle. We make 23 small holes of the same diameter according to the applied markings.Using a sickle knife, carefully remove burrs from all holes.

On the front side of the rectangular workpiece, where one large and 23 small holes have already been made, we mark two symmetrically located slots with a distance from the ends of 1.5 cm and a width of 1.5 cm, which will also go along the sides of the workpiece, slightly short of to the opposite wide side.

Carefully cut the slits using a mini-drill and cutting disc and remove the strips of plastic, helping yourself with a sickle-shaped knife. We also use it to clean the edges of the slots.

On the back side of the lamp body blank, at one end we mark and drill two small holes with a mini-drill, one below the other, and clean them with a sickle-shaped knife.

Using a small piece of sandpaper of suitable grit, we finally sand all the cutting and drilling areas of the lamp body.

We apply paint from an aerosol can to the future body of our homemade lamp and make sure that it is applied evenly over the entire surface and without smudges.

In accordance with the dimensions of the lamp body 12x6x24 cm, mark a sheet of translucent PVC plastic for cutting and cut out a piece of 24x24 cm using scissors. Using a marker, draw two straight lines parallel to the edges and at a distance of 6 cm from them.

We bend the plastic sheet along the straight lines and get a U-shaped profile, which we insert into the lamp body so that the wide side is adjacent to the front panel from the inside and covers the large and small holes.

We glue the U-shaped matte plastic with a glue gun to the lamp body at the corners and let the connection harden and set.

We pass a copper two-core wire through the upper hole made on the back side of the lamp housing so that the cartridge at one end is inside the housing.

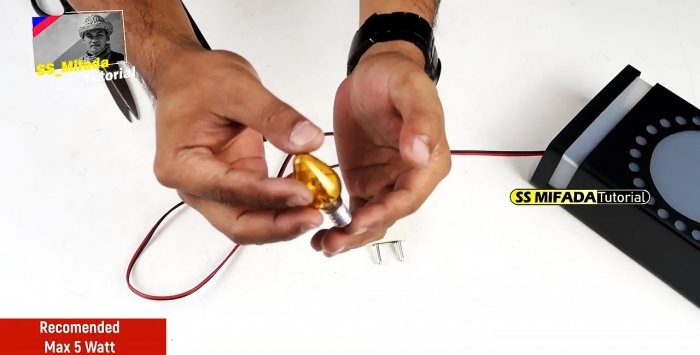

We attach an electrical plug to the second end of the wire, and screw an incandescent light bulb with a colored bulb with a power of no more than 5 watts into the socket in order to preserve the plastic from which our lamp is mainly assembled.

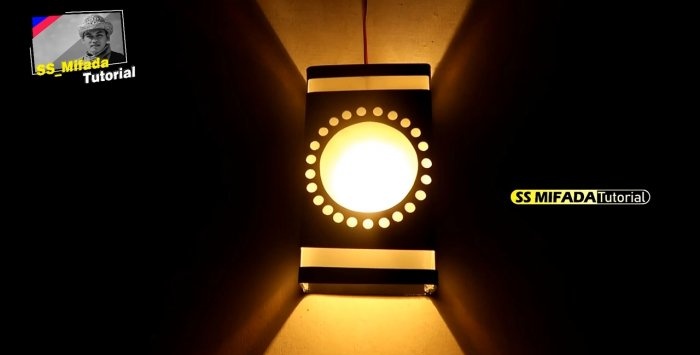

We plug the plug into the electrical outlet so that the light bulb inside the body of our homemade product lights up. As a result, we will witness an unusually beautiful glow of our decorative lamp, the effect of which will increase even more if we place it in a dark place.

Plastic dust poses a serious danger to your health, so a respiratory mask will be a good idea for the entire time you are working on a PVC pipe lamp. Gloves and safety glasses are also a good idea.

Will need

To materialize this creative idea into a beautiful product, we need to have:

- a piece of 10 cm PVC pipe about 30 cm long;

- paper;

- wooden box or beam 12×6×30 cm;

- a small piece of matte PVC plastic;

- electrical materials (wire, plug, socket, light bulb).

You should also get:

- metal ruler and marker;

- Dremel;

- milling cutter with attachments;

- sickle knife;

- sandpaper;

- a can of aerosol paint;

- glue gun.

Algorithm for making a lamp from PVC pipe

On the pipe blank we mark a section 24 cm long. Using a sheet of paper, we make circular lines on the side surface of the plastic pipe according to the markings.

Using a mini-grinder, using the circular markings, we cut off the excess from the plastic pipe blank.

We place a wooden box on the desktop that will serve as a template. Let’s check its cross-sectional dimensions once again: they should be 12x6 cm, which is acceptable as a template for a PVC pipe with a diameter of 10 cm.

We twist a sheet of paper into a bundle and set it on fire at one end from an external fire source (lighter, matches, etc.).

The thermal energy from a burning sheet of paper will be quite enough to soften the material of the plastic pipe, mainly on one side. This method is for those who do not have a hair dryer.

Then quickly, before the plastic has cooled, we insert a wooden template inside the pipe and form a rectangular one from the round section along the entire length, pushing the wooden box along the pipe until it appears on the other side of the pipe blank.

We leave the template in the pipe until the plastic cools down and takes on a stable rectangular cross-sectional shape, after which it can be removed from there. After making sure that the shape of the rectangular plastic element is without flaws, we process the ends with a mini-drill, removing burrs and rounding the edges. We use the round ring left over from cutting a plastic pipe as a template for reproducing a circle in the center of the wide side of a rectangular plastic element.

Using a hand router, we cut out a circle according to the applied markings and clean the edges of the resulting hole by changing the nozzle.

At a certain and equal distance from the edge of the hole, we mark 23 points, evenly spaced around the circumference of a large circle. We make 23 small holes of the same diameter according to the applied markings.Using a sickle knife, carefully remove burrs from all holes.

On the front side of the rectangular workpiece, where one large and 23 small holes have already been made, we mark two symmetrically located slots with a distance from the ends of 1.5 cm and a width of 1.5 cm, which will also go along the sides of the workpiece, slightly short of to the opposite wide side.

Carefully cut the slits using a mini-drill and cutting disc and remove the strips of plastic, helping yourself with a sickle-shaped knife. We also use it to clean the edges of the slots.

On the back side of the lamp body blank, at one end we mark and drill two small holes with a mini-drill, one below the other, and clean them with a sickle-shaped knife.

Using a small piece of sandpaper of suitable grit, we finally sand all the cutting and drilling areas of the lamp body.

We apply paint from an aerosol can to the future body of our homemade lamp and make sure that it is applied evenly over the entire surface and without smudges.

In accordance with the dimensions of the lamp body 12x6x24 cm, mark a sheet of translucent PVC plastic for cutting and cut out a piece of 24x24 cm using scissors. Using a marker, draw two straight lines parallel to the edges and at a distance of 6 cm from them.

We bend the plastic sheet along the straight lines and get a U-shaped profile, which we insert into the lamp body so that the wide side is adjacent to the front panel from the inside and covers the large and small holes.

We glue the U-shaped matte plastic with a glue gun to the lamp body at the corners and let the connection harden and set.

We pass a copper two-core wire through the upper hole made on the back side of the lamp housing so that the cartridge at one end is inside the housing.

We attach an electrical plug to the second end of the wire, and screw an incandescent light bulb with a colored bulb with a power of no more than 5 watts into the socket in order to preserve the plastic from which our lamp is mainly assembled.

We plug the plug into the electrical outlet so that the light bulb inside the body of our homemade product lights up. As a result, we will witness an unusually beautiful glow of our decorative lamp, the effect of which will increase even more if we place it in a dark place.

Attention!

Plastic dust poses a serious danger to your health, so a respiratory mask will be a good idea for the entire time you are working on a PVC pipe lamp. Gloves and safety glasses are also a good idea.

Watch the video

Similar master classes

Particularly interesting

Comments (0)