Methods for cutting threads on propylene pipes

A situation cannot be ruled out when it is urgently necessary to cut a thread in a propylene pipe or coupling, but there are no special devices for this. You can get out of this predicament by having at hand a minimum of non-scarce materials and some common tools.

To figure out how to cut a thread in a given case, we need to stock up on: a piece of polypropylene pipe, a plastic and metal coupling, as well as linen winding and a sealing compound in a tube.

We will use the following tools and devices:

Sequence of thread cutting in different situations

We may have a combination of certain materials and tools in stock. What course of action should we choose in this case?

This tool is designed for cutting external threads on cylindrical surfaces of almost any metal material, including steel. Therefore, it seems that dealing with a polypropylene pipe will not be difficult.

Holding the die with one hand, use a pipe wrench to screw the end of the plastic pipe into the tool. The most important thing is to ensure grip. After which, by applying some effort to the wrench, we can make several turns of thread on the surface of the pipe. It is possible that the key will slip and deep grooves may remain on it. In fact, you should avoid doing this to avoid weakening the pipe. After unscrewing the workpiece from the die, we make sure that the thread is satisfactory.

In this case, thread cutting is easier and proceeds as standard. We heat the end of the pipe according to the instructions for the device and begin to screw it into a metal coupling with an internal thread. In this case, it is necessary to balance the pressing force and the rotation speed.

Having screwed the pipe to the required depth, let it stand for some time so that it cools a little and decreases in size. After which it will easily unscrew from the metal coupling. Inspection shows that the thread does not start from the end of the pipe, but at some distance, but it looks quite suitable and reliable.

We also heat a plastic coupling on one side on the welding machine and screw a metal coupling with a thread at the end into it. After waiting a short time, we separate the parts and make sure that the thread is excellent.

We repeat the same operation for the other end of the plastic part.Moreover, the indentation force and rotation speed should be similar to the first case. We additionally check the quality of the thread by screwing in and unscrewing the metal coupling.

To do this, we assemble an assembly of plastic elements in which threads have been cut, as well as a metal coupling, since such a combination is quite possible in practice. To seal joints everywhere we use linen winding and a special sealing compound.

Some connections can be tightened by hand, while others require the additional use of one or two pipe wrenches.

We connect the assembly to the pressurized water supply system, and plug the open end with a factory threaded plug.

We consistently apply pressure to the assembly, fixing its value at the following readings: 1, 2, 3, 4, 6, 8, 10, 12, 14, 16, 20, 25, 30, 40, 45 bar. After each pressure fixation, we check the tightness of the assembly. We make sure that it is present at any pressure, including the maximum value of 45 bar.

Since our assembly withstood a pressure of 45 bar, which never occurs in the home water supply, in the garden and in the country, you can safely cut threads in propylene pipes and couplings in various ways manually, since the pressure on these objects does not exceed 8 bar.

Will need

To figure out how to cut a thread in a given case, we need to stock up on: a piece of polypropylene pipe, a plastic and metal coupling, as well as linen winding and a sealing compound in a tube.

We will use the following tools and devices:

- thread cutting die;

- machine for welding plastic products;

- two pipe wrenches;

- a test bench designed for pressures up to 50 bar;

- screw plug.

Sequence of thread cutting in different situations

We may have a combination of certain materials and tools in stock. What course of action should we choose in this case?

Die and polypropylene pipe

This tool is designed for cutting external threads on cylindrical surfaces of almost any metal material, including steel. Therefore, it seems that dealing with a polypropylene pipe will not be difficult.

Holding the die with one hand, use a pipe wrench to screw the end of the plastic pipe into the tool. The most important thing is to ensure grip. After which, by applying some effort to the wrench, we can make several turns of thread on the surface of the pipe. It is possible that the key will slip and deep grooves may remain on it. In fact, you should avoid doing this to avoid weakening the pipe. After unscrewing the workpiece from the die, we make sure that the thread is satisfactory.

Welding machine, metal coupling and pipe

In this case, thread cutting is easier and proceeds as standard. We heat the end of the pipe according to the instructions for the device and begin to screw it into a metal coupling with an internal thread. In this case, it is necessary to balance the pressing force and the rotation speed.

Having screwed the pipe to the required depth, let it stand for some time so that it cools a little and decreases in size. After which it will easily unscrew from the metal coupling. Inspection shows that the thread does not start from the end of the pipe, but at some distance, but it looks quite suitable and reliable.

Welding machine, metal and plastic coupling

We also heat a plastic coupling on one side on the welding machine and screw a metal coupling with a thread at the end into it. After waiting a short time, we separate the parts and make sure that the thread is excellent.

We repeat the same operation for the other end of the plastic part.Moreover, the indentation force and rotation speed should be similar to the first case. We additionally check the quality of the thread by screwing in and unscrewing the metal coupling.

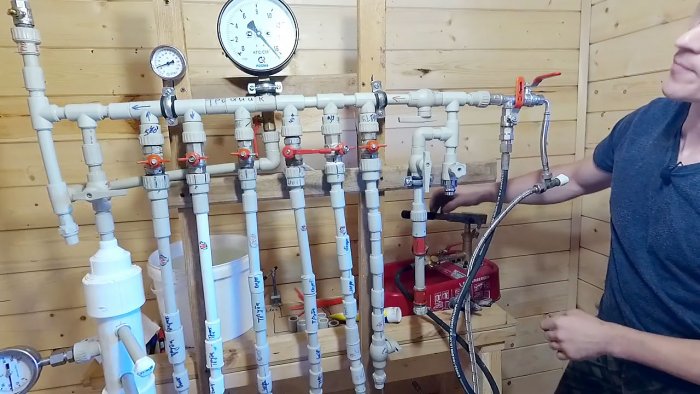

Checking threaded connections under pressure

To do this, we assemble an assembly of plastic elements in which threads have been cut, as well as a metal coupling, since such a combination is quite possible in practice. To seal joints everywhere we use linen winding and a special sealing compound.

Some connections can be tightened by hand, while others require the additional use of one or two pipe wrenches.

We connect the assembly to the pressurized water supply system, and plug the open end with a factory threaded plug.

We consistently apply pressure to the assembly, fixing its value at the following readings: 1, 2, 3, 4, 6, 8, 10, 12, 14, 16, 20, 25, 30, 40, 45 bar. After each pressure fixation, we check the tightness of the assembly. We make sure that it is present at any pressure, including the maximum value of 45 bar.

Conclusion

Since our assembly withstood a pressure of 45 bar, which never occurs in the home water supply, in the garden and in the country, you can safely cut threads in propylene pipes and couplings in various ways manually, since the pressure on these objects does not exceed 8 bar.

Watch the video

Similar master classes

Particularly interesting

Comments (3)