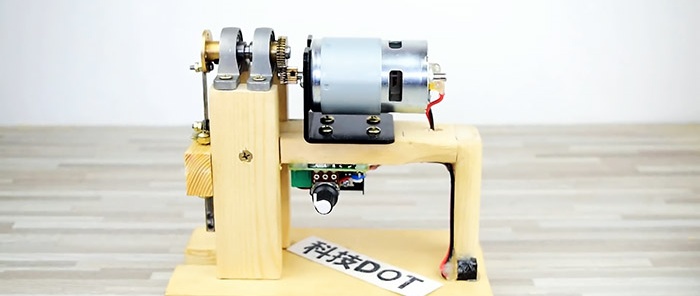

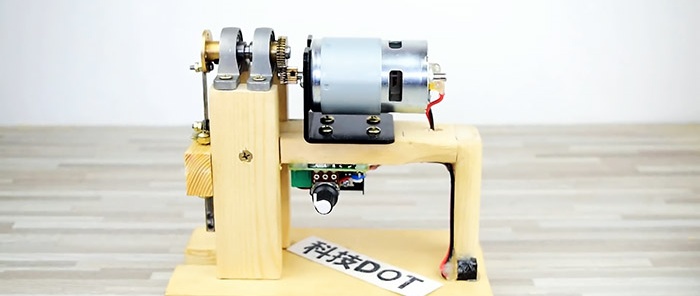

How to make a 12 V electric jigsaw from scrap materials

An electric jigsaw is a multifunctional tool designed for shaped and unidirectional cutting of various sheet materials. It is used when performing repair and construction work, as well as for making DIY crafts. If necessary, such a tool can be assembled independently using available materials.

A homemade invention will have the functions of a factory analogue and low-voltage power supply, while assembly will cost much less than buying a new electric jigsaw. Our homemade product will be adapted to standard saw blades, which will eliminate problems with finding consumables to complete the work.

Let's start with the parts that will be needed for assembly.

The supporting plane and body elements are easiest to make from wood. This material is easily accessible, durable and easy to process. For assembly, you should prepare boards of the following dimensions (length*width*thickness, mm):

As a drive we use a compact DC motor with a power of 150 W, operating from a network with a voltage of 12 V. The diameter of the output shaft is 5 mm. For the drive, you must additionally purchase a support and a speed controller.

You should also prepare the following materials for assembly:

We put the coupling on the steel rod and fix it with a hexagon.

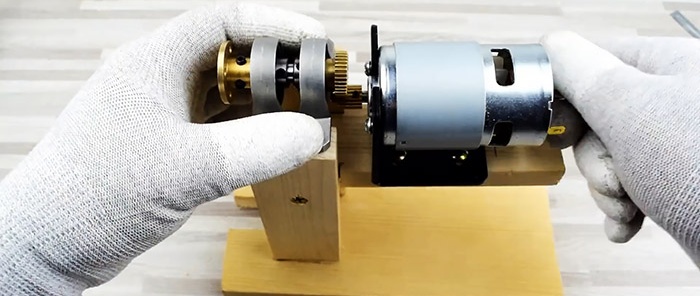

Next comes the bearings in the supports and a large gear.

We put and fix the small gear on the motor shaft.

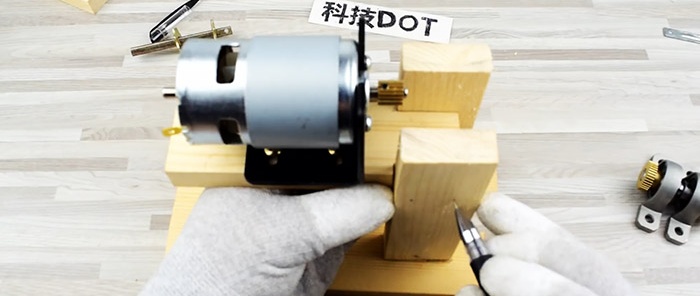

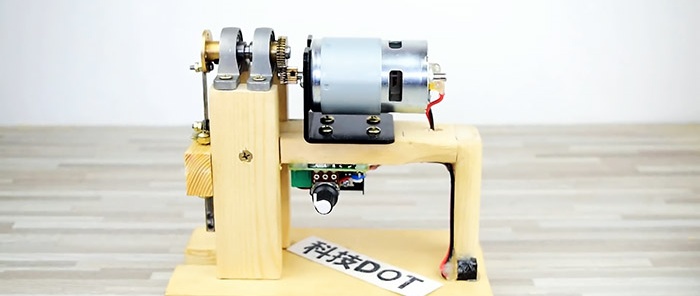

We assemble the housing, transmission and secure the engine with a support. We use wood screws as connecting elements - with a large thread pitch.

We make a fastening element for a saw blade from a square steel rod. To do this, you need to make two longitudinal cuts and drill holes on the side, as shown in the photo.

We make holes in the saw blade.

We connect the coupling and fasteners for the canvas using a metal strip.

We manufacture and fasten the last element of the body.

We attach the speed controller to silicone.

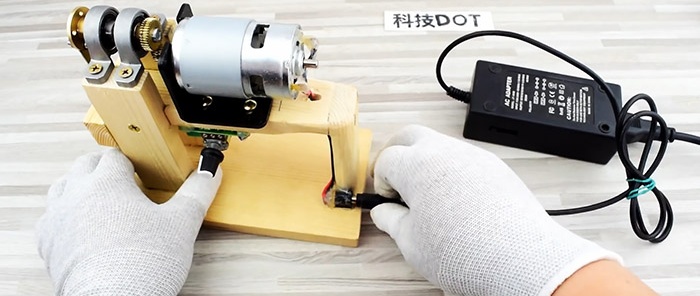

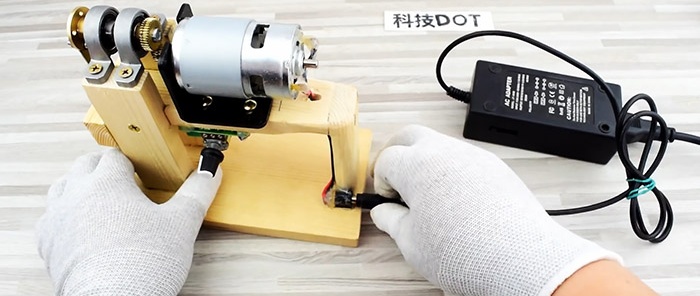

We connect the wires and add a connector for connecting a power supply or transformer.

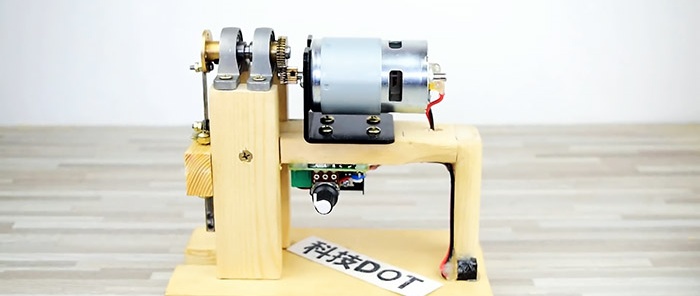

The electric jigsaw is ready.

It cuts perfectly.

The power of the device allows you to work with docks up to 15 mm thick.To connect to a household network, you will need to purchase a step-down transformer or power supply.

During assembly, scrap materials were used - if necessary, you can modernize the design.

A homemade invention will have the functions of a factory analogue and low-voltage power supply, while assembly will cost much less than buying a new electric jigsaw. Our homemade product will be adapted to standard saw blades, which will eliminate problems with finding consumables to complete the work.

Let's start with the parts that will be needed for assembly.

Materials used

The supporting plane and body elements are easiest to make from wood. This material is easily accessible, durable and easy to process. For assembly, you should prepare boards of the following dimensions (length*width*thickness, mm):

- 190*95*14 – 1 piece;

- 115*35*14 – 2 pcs.;

- 130*35*14 – 1 piece;

- 60*30*14 – 1 pc.

As a drive we use a compact DC motor with a power of 150 W, operating from a network with a voltage of 12 V. The diameter of the output shaft is 5 mm. For the drive, you must additionally purchase a support and a speed controller.

You should also prepare the following materials for assembly:

- Ball bearing in a support with a hole diameter of 8 mm – 2 pcs.;

- Straight round steel rod 50 mm long and 8 mm in diameter;

- To transmit torque, you will need a flange coupling and two gears - 15 and 35 teeth, with seat diameters of 5 and 8 mm, respectively.

- Metal strip with holes (length – 35 mm);

- Square steel rod and two flat washers with external teeth.

- Saw blade.

Jigsaw assembly procedure

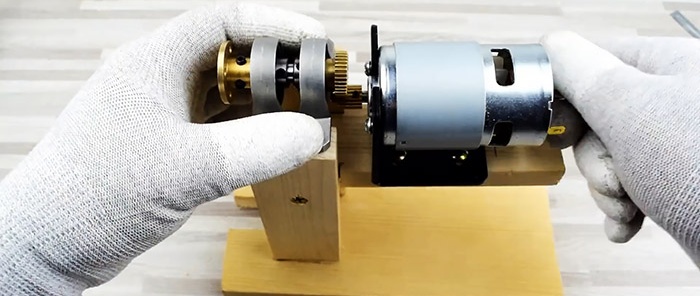

We put the coupling on the steel rod and fix it with a hexagon.

Next comes the bearings in the supports and a large gear.

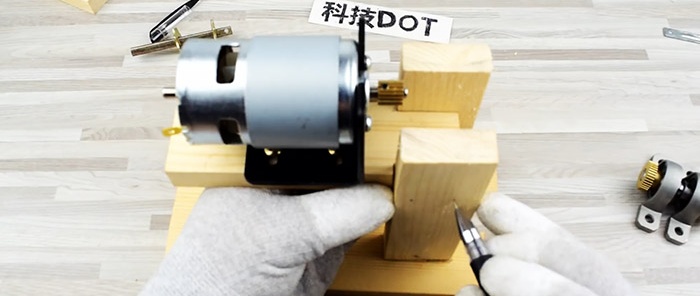

We put and fix the small gear on the motor shaft.

We assemble the housing, transmission and secure the engine with a support. We use wood screws as connecting elements - with a large thread pitch.

We make a fastening element for a saw blade from a square steel rod. To do this, you need to make two longitudinal cuts and drill holes on the side, as shown in the photo.

We make holes in the saw blade.

We connect the coupling and fasteners for the canvas using a metal strip.

We manufacture and fasten the last element of the body.

We attach the speed controller to silicone.

We connect the wires and add a connector for connecting a power supply or transformer.

The electric jigsaw is ready.

It cuts perfectly.

Conclusion

The power of the device allows you to work with docks up to 15 mm thick.To connect to a household network, you will need to purchase a step-down transformer or power supply.

During assembly, scrap materials were used - if necessary, you can modernize the design.

Watch the video

Similar master classes

Particularly interesting

Comments (1)