How to make a crown of any size from a pipe

If it is necessary to drill a large diameter hole in wood, a crown is required. Moreover, the larger the hole needed, the more expensive the cost of such a crown. If the need for this tool is one-time, then there is no point in buying it. In this case, you can make the crown yourself.

To make a crown, you need to prepare a piece of steel pipe of equal or several millimeters smaller diameter than the hole being piped. The length of the workpiece should slightly exceed the drilling depth. The edges of the pipe need to be trimmed.

On one side, the pipe needs to be plugged. To do this, a circle is cut out of sheet steel. A hole is drilled in the center of the plug to install an M12 bolt. The bolt is inserted into the circle and welded. The plug is then welded to the pipe.

Next, you need to make cutting tips similar to those used on concrete crowns. Their production requires hardened steel. You can use a sewing machine shaft or something similar.Before use, make sure that the shaft is completely hardened. To do this, a small piece is cut off from it. If the steel is homogeneous in cross-section without traces of carburization, then it can be used.

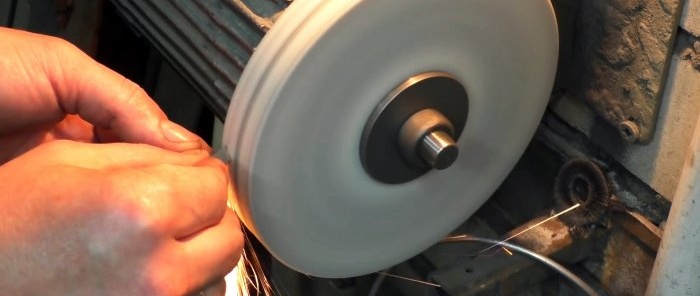

The shaft needs to be ground into a block. It is important not to overheat the steel so as not to loosen it. When grooving, the shaft should be periodically cooled in water. One side of the bar is made with a bevel. Then it is cut into 4 pieces literally 5-10 mm each.

Markings are made on the pipe for welding the teeth. Grooves are cut along it corresponding to the width of the soldering. Then the teeth are welded.

To position a homemade crown when drilling, if it is large, you need to cut a circle from a board, plywood or chipboard equal to its internal diameter. It can be made with a jigsaw. Then the circle is screwed to the drilling site with several self-tapping screws. A crown is installed on top of it, clamped with a bolt in the drill chuck. The limiter will allow you to assign a hole. Having gone deeper a few centimeters, the circle can be removed if it is in the way.

A homemade crown may drill worse than a purchased one, but the cost of its production is very low, so the tool is well worth attention. When using a 133 mm pipe as its base, it was possible to make a hole in a wooden wall for installing an exhaust fan without any problems. When making such large crowns, it is important not to make more than 4 teeth, since it will be difficult for the drill to rotate it.

Materials:

- steel pipe equal to the diameter of the required hole;

- Sheet steel;

- bolt M12;

- hardened shaft

The process of making a crown for wood

To make a crown, you need to prepare a piece of steel pipe of equal or several millimeters smaller diameter than the hole being piped. The length of the workpiece should slightly exceed the drilling depth. The edges of the pipe need to be trimmed.

On one side, the pipe needs to be plugged. To do this, a circle is cut out of sheet steel. A hole is drilled in the center of the plug to install an M12 bolt. The bolt is inserted into the circle and welded. The plug is then welded to the pipe.

Next, you need to make cutting tips similar to those used on concrete crowns. Their production requires hardened steel. You can use a sewing machine shaft or something similar.Before use, make sure that the shaft is completely hardened. To do this, a small piece is cut off from it. If the steel is homogeneous in cross-section without traces of carburization, then it can be used.

The shaft needs to be ground into a block. It is important not to overheat the steel so as not to loosen it. When grooving, the shaft should be periodically cooled in water. One side of the bar is made with a bevel. Then it is cut into 4 pieces literally 5-10 mm each.

Markings are made on the pipe for welding the teeth. Grooves are cut along it corresponding to the width of the soldering. Then the teeth are welded.

To position a homemade crown when drilling, if it is large, you need to cut a circle from a board, plywood or chipboard equal to its internal diameter. It can be made with a jigsaw. Then the circle is screwed to the drilling site with several self-tapping screws. A crown is installed on top of it, clamped with a bolt in the drill chuck. The limiter will allow you to assign a hole. Having gone deeper a few centimeters, the circle can be removed if it is in the way.

A homemade crown may drill worse than a purchased one, but the cost of its production is very low, so the tool is well worth attention. When using a 133 mm pipe as its base, it was possible to make a hole in a wooden wall for installing an exhaust fan without any problems. When making such large crowns, it is important not to make more than 4 teeth, since it will be difficult for the drill to rotate it.

Watch the video

Similar master classes

Particularly interesting

Comments (3)