How to make a powerful 12V vacuum cleaner from plastic bottles

The engine from a broken cordless power tool can be used to make a mini vacuum cleaner, which is useful for cleaning the interior of a car. It is very light, easy to clean, and will also help out when collecting scattered small items.

The blades are removed from the cooler, then the pressed shaft is pulled out of them. If it does not come out, then it should be heated with a soldering iron and pulled out hot.

Then the blades are mounted on the shaft of the existing electric motor so that the blowing is directed towards the motor housing.

The bottoms are cut off from two plastic bottles.

One is at the very bottom along the embossing line, and the other is higher, approximately in the middle. Holes are made in the bottoms to match the diameter of the engine housing. If there is no crown, then they can be melted with a heated pipe.

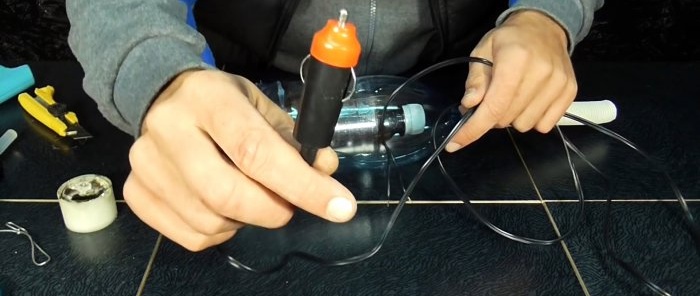

The motor is inserted into the long bottom with the blades inward and glued with hot glue.

Then a smaller bottom is put on it from the outside and also fixed with glue. The seam between the walls of the bottles is also filled with hot glue.

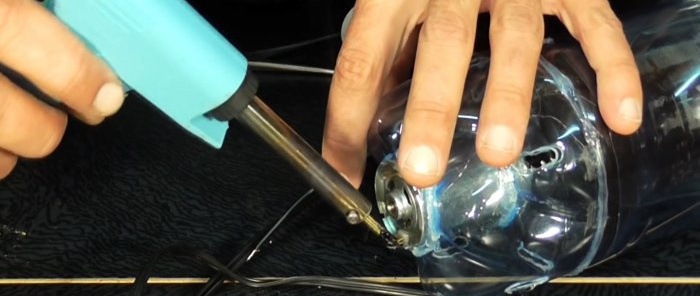

The neck is cut off from a plastic bottle with a long neck, and small holes are made in it with a soldering iron.

The same holes are burned into its lid. Then you need to make wide holes in the glued bottoms so that the air pumped by the fan can freely exit through them.

The perforated neck must be inserted into the remaining half of the bottle after cutting off the low bottom. They are then inserted into the engine casing.

To make the handle of the vacuum cleaner, you can cut off another long neck from the bottle. The shoulders are cut out on it, and it is glued with hot glue onto the body of the assembled vacuum cleaner. It looks like a hair dryer.

A hole is cut in the lid of the vacuum cleaner spout and a corrugated hose is inserted into it.

You also need to connect the power cord. To do this, twist the cap off the handle of the vacuum cleaner, drill it and insert the cable through it. Then you need to tie it in a knot so that it does not break out, and remove the remaining tail of the wire through the side hole in the handle. Next, the end of the cord is soldered to the motor contacts. A plug for the car cigarette lighter is installed on the second edge of the wire.

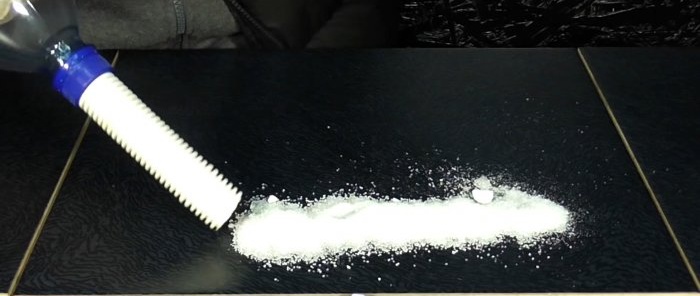

In this form, the vacuum cleaner can be used to collect scattered small items, for example, seeds, balls, sawdust, shavings.

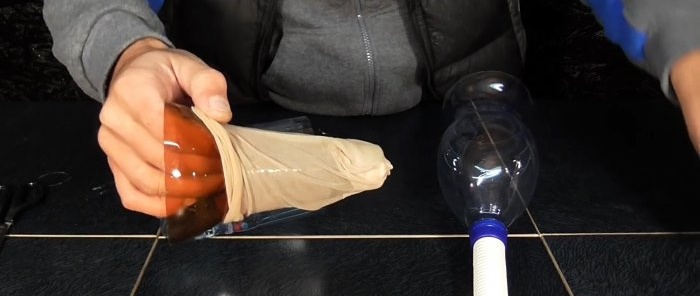

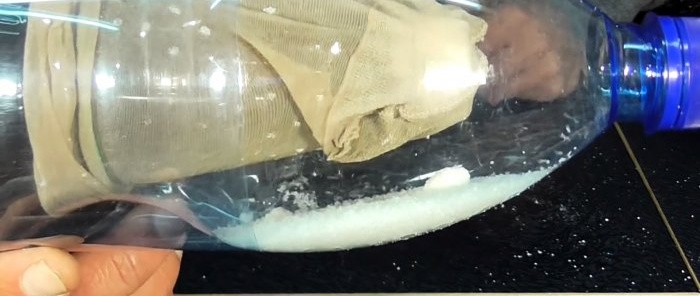

If it is necessary to collect dust, then a stocking or sock is pulled over the inner neck with fine perforations.

Materials:

- high speed motor 12V -

- computer cooler (possibly broken);

- plastic bottles 2 l;

- stocking or sock;

- electrical cable;

- car cigarette lighter plug;

- corrugated hose 20-25 mm

Vacuum cleaner manufacturing process

The blades are removed from the cooler, then the pressed shaft is pulled out of them. If it does not come out, then it should be heated with a soldering iron and pulled out hot.

Then the blades are mounted on the shaft of the existing electric motor so that the blowing is directed towards the motor housing.

The bottoms are cut off from two plastic bottles.

One is at the very bottom along the embossing line, and the other is higher, approximately in the middle. Holes are made in the bottoms to match the diameter of the engine housing. If there is no crown, then they can be melted with a heated pipe.

The motor is inserted into the long bottom with the blades inward and glued with hot glue.

Then a smaller bottom is put on it from the outside and also fixed with glue. The seam between the walls of the bottles is also filled with hot glue.

The neck is cut off from a plastic bottle with a long neck, and small holes are made in it with a soldering iron.

The same holes are burned into its lid. Then you need to make wide holes in the glued bottoms so that the air pumped by the fan can freely exit through them.

The perforated neck must be inserted into the remaining half of the bottle after cutting off the low bottom. They are then inserted into the engine casing.

To make the handle of the vacuum cleaner, you can cut off another long neck from the bottle. The shoulders are cut out on it, and it is glued with hot glue onto the body of the assembled vacuum cleaner. It looks like a hair dryer.

A hole is cut in the lid of the vacuum cleaner spout and a corrugated hose is inserted into it.

You also need to connect the power cord. To do this, twist the cap off the handle of the vacuum cleaner, drill it and insert the cable through it. Then you need to tie it in a knot so that it does not break out, and remove the remaining tail of the wire through the side hole in the handle. Next, the end of the cord is soldered to the motor contacts. A plug for the car cigarette lighter is installed on the second edge of the wire.

In this form, the vacuum cleaner can be used to collect scattered small items, for example, seeds, balls, sawdust, shavings.

If it is necessary to collect dust, then a stocking or sock is pulled over the inner neck with fine perforations.

Watch the video

Similar master classes

Particularly interesting

Comments (0)