Making a mobile stove out of a barrel for burning garden waste

After cleaning the garden, a lot of leaves and branches remain, burning of which in the area is undesirable, as it leads to the formation of burnt spots. For these purposes it is better to use a special oven. It does not touch the ground, so the flames in it do not harm the landscape in any way. You can make such a stove yourself from a steel barrel.

You need to make a loading door in the lid of the barrel. It should take up most of the lid. First, the side of the door is cut out to install the hinges.

Without cutting the remaining sides, you need to put 2 loops on the rivets, so everything is guaranteed to open perfectly and stay straight.

Then the door is cut to the end.

A mounting bracket is installed on the barrel wall on the opposite side of the hinges using rivets. It will serve as a limiter for the door.

Then an overhead handle is mounted on the door.

On the remaining untouched part of the lid, a circle is drawn for inserting the chimney.

At the bottom of the barrel, under the handle of the loading door, a small window is cut into the wall to blow in air and remove ash. This door is made in a similar way. First, 2 loops are installed, then the remaining sides are cut.

Since it is located on the side, you will need to install a door latch on it. In this case, the door will not open from the wind. To add rigidity, you will need to bend 2 arcs from the reinforcement and weld them on the inside of the small door.

Then you need to make the grate bars. To do this, a ring is bent from the reinforcement along the inner diameter of the barrel. Rods are welded onto it in increments of several centimeters. Once ready, the grate bars are inserted into the barrel and welded slightly above the side door.

So that the barrel does not stand on the ground and can be easily transported, cart wheels are welded to the bottom. Opposite them, a rod is welded as a third support.

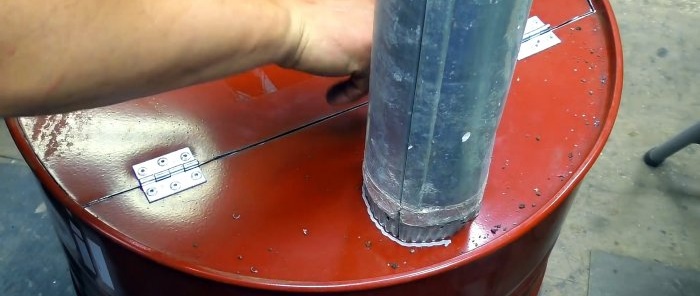

After this, the stove is turned over and a chimney pipe is inserted into it. A hole is made in the side of the barrel so that the chimney can also be drilled. After this they are tightened with a bolt. This will provide a fairly reliable fastening without welding, which will allow you to remove the chimney for more compact storage of the stove.

For convenient rolling of the barrel, you need to make a transport handle. It bends out of the reinforcement. A U-shaped blank is bent and welded onto the barrel from the chimney side. You can put a hose on it so that the relief of the reinforcement does not put pressure on your palm.

As they appear, burning garden waste and paper are dumped into the stove. It is stored in it until the firebox is full. After this, the garbage is set on fire.The resulting ash is collected through a side door and used as fertilizer.

Materials:

- barrel 200 l;

- door hinges – 4 pcs.;

- door latch;

- overhead door handle;

- mounting perforated corner;

- chimney pipe;

- fittings;

- wheels for the trolley – 2 pcs.

The process of making a waste incinerator

You need to make a loading door in the lid of the barrel. It should take up most of the lid. First, the side of the door is cut out to install the hinges.

Without cutting the remaining sides, you need to put 2 loops on the rivets, so everything is guaranteed to open perfectly and stay straight.

Then the door is cut to the end.

A mounting bracket is installed on the barrel wall on the opposite side of the hinges using rivets. It will serve as a limiter for the door.

Then an overhead handle is mounted on the door.

On the remaining untouched part of the lid, a circle is drawn for inserting the chimney.

At the bottom of the barrel, under the handle of the loading door, a small window is cut into the wall to blow in air and remove ash. This door is made in a similar way. First, 2 loops are installed, then the remaining sides are cut.

Since it is located on the side, you will need to install a door latch on it. In this case, the door will not open from the wind. To add rigidity, you will need to bend 2 arcs from the reinforcement and weld them on the inside of the small door.

Then you need to make the grate bars. To do this, a ring is bent from the reinforcement along the inner diameter of the barrel. Rods are welded onto it in increments of several centimeters. Once ready, the grate bars are inserted into the barrel and welded slightly above the side door.

So that the barrel does not stand on the ground and can be easily transported, cart wheels are welded to the bottom. Opposite them, a rod is welded as a third support.

After this, the stove is turned over and a chimney pipe is inserted into it. A hole is made in the side of the barrel so that the chimney can also be drilled. After this they are tightened with a bolt. This will provide a fairly reliable fastening without welding, which will allow you to remove the chimney for more compact storage of the stove.

For convenient rolling of the barrel, you need to make a transport handle. It bends out of the reinforcement. A U-shaped blank is bent and welded onto the barrel from the chimney side. You can put a hose on it so that the relief of the reinforcement does not put pressure on your palm.

As they appear, burning garden waste and paper are dumped into the stove. It is stored in it until the firebox is full. After this, the garbage is set on fire.The resulting ash is collected through a side door and used as fertilizer.

Watch the video

Similar master classes

Particularly interesting

Comments (0)