2 useful tools from one worn step drill

Sharpening dull step drills is not at all easy, so many people prefer to replace them. In this case, the old tool can be converted into 2 useful devices for the workshop.

What you will need:

- worn step drill;

- rod 8-12 mm;

- drill;

- welding;

- Bulgarian.

Drill conversion process

The drill needs to be cut into 2 parts. The half with the shank can be converted into a conical countersink, and the tip into a scriber and core. To cut a drill evenly, you need to install it in a drill and clamp it in a vice. The cut is made with a grinder with the drill turned on.

Then you need to sharpen the part with the shank to a cone. This can also be done using a grinder and a drill. The angle between the faces of the cone should be 120 degrees.

Next, the workpiece is clamped in a vice by the shank, and 2 longitudinal grooves are cut on it at an angle of 50-55 degrees.

After this, the countersink is ready for use.

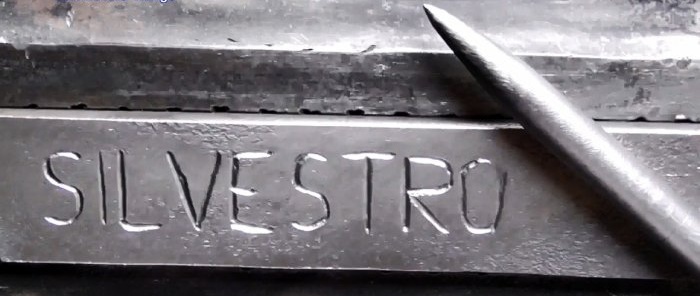

The remaining tip of the step drill can be welded to the end of the rod.

The welding seam between them is ground off along with the steps; only the tip needs to be left.

The result is a very hard core that can also be used as a scriber.

Watch the video

Similar master classes

Particularly interesting

Comments (0)