How to make your own thermal paste

Each of us has probably found ourselves in a situation where we don’t have the right item or material at hand at the right time. Moreover, he is not in the apartment at all. The store is closed, or the required product is not there... it doesn’t matter. But, if you think a little and be smart, there will always be a way out. Today we will talk about thermal paste. Not finding thermal paste in a local provincial store, I remembered a recipe that I had already used to prepare such paste a couple of years ago. This, of course, is not a factory recipe, and the quality is far from the same, but still, for the first time (for a month for sure!), before buying real paste, this substance will help very well. And if you have some silver on your shelf with paints, then the issue can be resolved in literally 10 minutes.

Will need

- Aluminum pigment powder (PAP-1) or in common parlance – silver powder, 1 teaspoon.

- Litol, or solid oil. 0.5 teaspoon

- Fine graphite grease 0.5 tsp. Can be replaced with crushed or grated pencil graphite 0.5 tsp.

- Fine aluminum filings 1 teaspoon (not so important. If possible).

- Syringe 2 sq.cm.

- Jar lid and stick (for stirring).

- Medical gloves.

Making thermal paste

If you have silver in your supplies, then getting the rest of the ingredients is not a problem. Litol can be replaced with solid oil, although in this case you will have to add twice as much graphite. Why lithol? Because lithium greases are more heat-resistant than grease. In my example, lithol is already mixed with graphite lubricant - leftovers from last time. So, take half a teaspoon of lithol and mix it with half a teaspoon of graphite lubricant (accordingly, if solid oil, then 1 full teaspoon of graphite). Stir until smooth. Add one teaspoon of silver to the mixture.

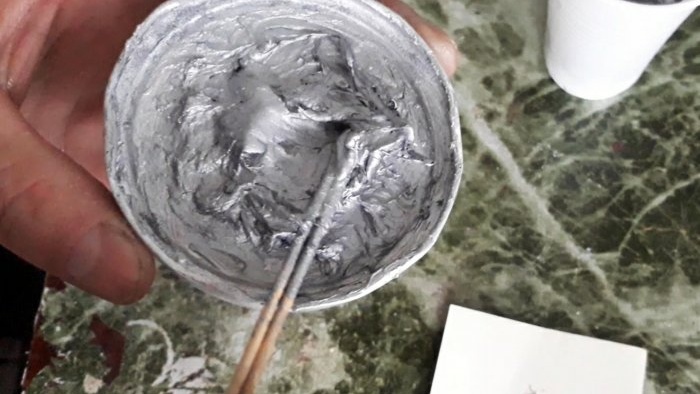

Stir CAREFULLY - silver is a very light and volatile material. It would be a good idea to wear medical gloves and a respirator, which I conveniently forgot about. After the silver is completely mixed with lithol and graphite, a thick, silver-colored dough is obtained.

In principle, this can already be used, but for greater reliability, I added a spoonful of aluminum filings, which I collected and saved in advance after sawing one aluminum part in the shop.

And just rubbing a teaspoon of aluminum filings with a large file takes five minutes. Mix everything until smooth. Now the most tedious part of the job is to put the required amount of this paste into the syringe. We remove the piston part from the syringe, and carefully, using a stick, push the paste into the syringe flask.

I drew the amount I needed, connected the parts of the syringe, and wiped it with a cloth. You can use it!

I left the rest for a little experiment. I want to show that this paste is absolutely safe in terms of fire from high temperatures.Some people are wary of silver, rightly believing that it is a very flammable material. However, in combination with lithol and graphite, a completely non-flammable mixture is obtained, which you can clearly see in the video, in the tests of the paste. Even the heat of a hunting match melted the paste only in those places where it was adjacent to the match closely.

Of course, the paste did not ignite or spark. Well, as a test for its intended purpose, I’ll give an example using a USB lamp.

This Chinese diode lamp gets so hot that its rubber braid becomes soft like plasticine after half an hour of use. I have long wanted to attach an aluminum heat sink to it.

Unfortunately, I don’t have a suitable thermometer to measure the temperature difference “before” and “after,” but according to tactile sensations, the lamp heats up MUCH less. The lamp is warm, but not hot, and does not melt the braid of the lamp.

The most unexpected and hard-to-find material in this master class is silver. Not everyone may have it. The remaining components, or their substitutes, are simple and accessible to absolutely everyone.