Top 9 ways to desolder a chip

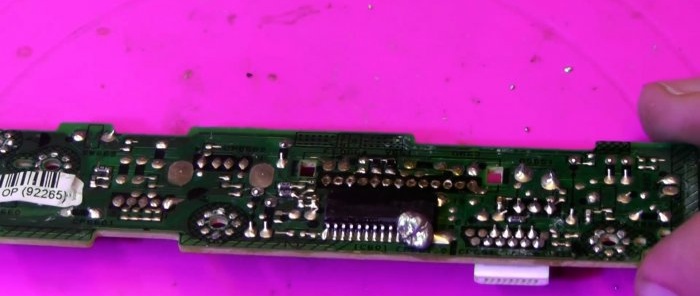

Beginners who are just starting to learn the basics of soldering have difficulty desoldering microcircuits. It's really not easy, but only if you don't use tricky tricks. Let's look at the best of them.

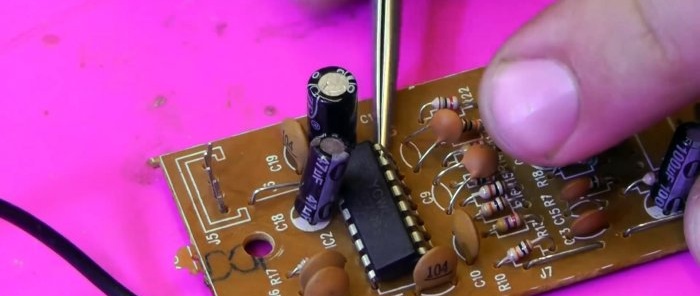

Soldering a microcircuit with a soldering iron

If you only have a soldering iron, then you need to lubricate the soldering area with flux and warm up all the outputs by moving the tip along them. From the reverse side, the microcircuit is pryed off with tweezers or a screwdriver. It needs to be pulled back. It is necessary to heat all the outputs evenly, and when they melt, the component is dismantled.

Using a syringe needle

The leads of the components are lubricated with flux, then they are heated one by one with a tip and a syringe needle is placed on them. Since it is made of steel, tin does not stick to it. As a result, the soldered leg of the component will remain inside it, and the needle itself will then easily come out of the solder that has solidified outside.

Working with a desoldering pump

It is very easy to desolder the chip with a desoldering pump. Before working on it, the trigger is cocked, then the solder on the leg is melted with a soldering iron. After this, the nozzle of the tool is placed on the liquid tin and the button is pressed. As a result, it absorbs all the solder.

Using braid (PSB wire)

You can use a special braid to absorb solder. It is moistened with flux and applied to the output of the microcircuit. You need to melt the tin, and it will flow onto the braid, since it is hygroscopic.

Instead of a purchased one, you can use braided TV cable. Due to its large size, it absorbs much more tin.

A stranded strand also pulls tin out of a regular cable. It's not as good as braid, but it works too.

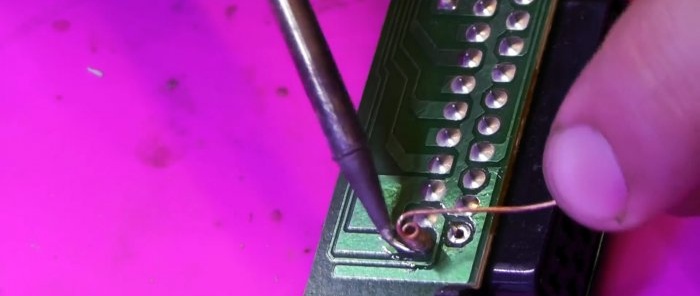

Application of a wire spiral

You can strip the wire and wind its copper core onto a needle or thin awl.

The resulting flux-wetted spiral is applied to the heated terminal of the component. The tin will flow into this tube and the leg will remain free. While the solder has not hardened, you can shake it out of the tool to use the spiral further.

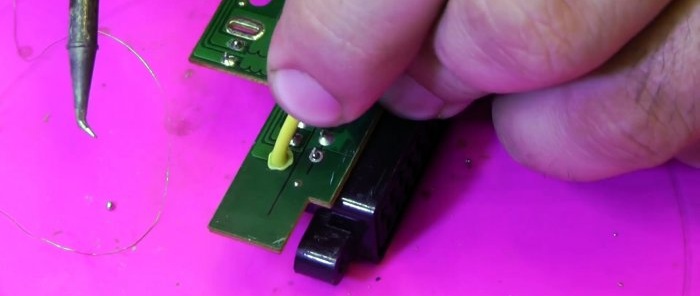

Solder removal by wire insulation tube

You need to remove the insulation from the wire. This tube is pulled onto a heated terminal with molten tin. You need to wait a couple of seconds and rip it off. All the solder will be in it, and the leg of the microcircuit will be freed.

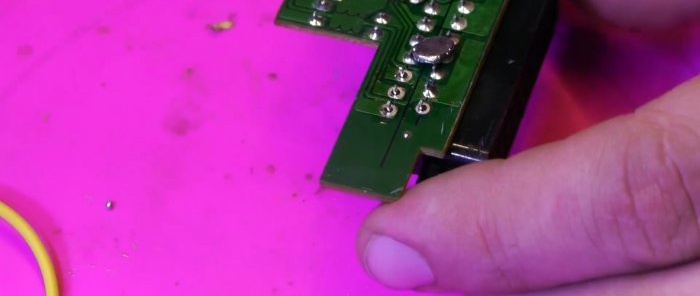

Solder thinning with Rose alloy

A small amount of Rose's alloy needs to be melted near the component's outputs to get it onto the solder. Tin diluted with it will melt at lower heat. This will allow you to heat all the legs with a soldering iron without overheating the board and remove the chip.

Removal with a hairdryer

The outputs of the microcircuit can be heated with a soldering hair dryer and simply remove the desired component. It is best at this moment to pull it off on the back with tweezers. It's quick and easy, but using a hair dryer causes the board to overheat.

Soldering with a hairdryer and Rose alloy

You can tin the legs of the microcircuit with Rose alloy, and then melt the diluted tin with a hairdryer. After this, the alloy must be removed so that during further soldering it does not spoil the fresh solder.

Watch the video

Similar master classes

10 useful life hacks with a soldering iron for radio electronics

When there is no hot air gun or infrared soldering iron

How to tin a soldering iron

Life hack: how to solder small parts with a soldering iron with a thick tip

Simple ULF on TDA2003

How to simply solder aluminum tightly with regular solder

Particularly interesting

Comments (0)