How to make a strong T-shaped connection of profile pipes without welding

Metal structures from profile pipes can be assembled without welding. For this purpose, many methods for connecting them have been developed. Let's consider a method of rigid T-shaped fastening of pipes at right angles.

Required tools:

- ruler;

- marker;

- Bulgarian;

- hammer;

- screwdriver

Process of T-shaped fastening of profile pipes

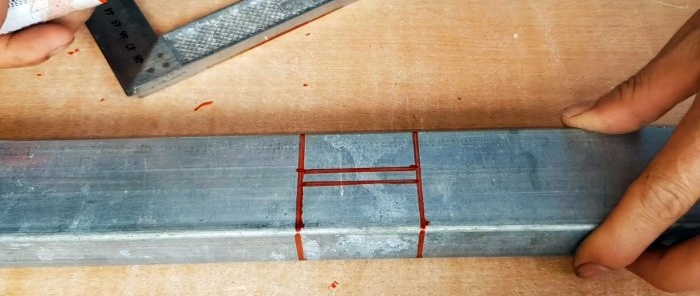

On the main pipe you need to make precise markings for the width of the pipe to be connected. It is applied around the entire circumference.

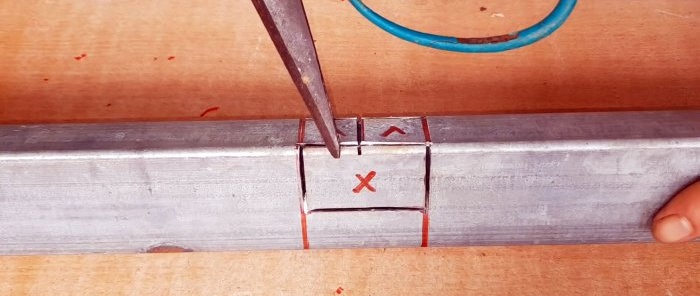

On the front sides of the pipe, longitudinal lines are required between the transverse lines. They are located opposite each other below the center. This is clearly visible in the photo. The required line is drawn below the central one drawn for clarity.

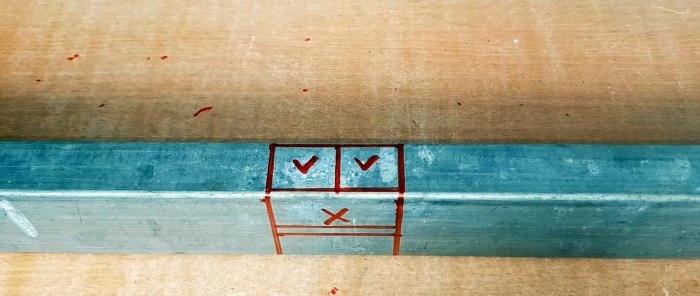

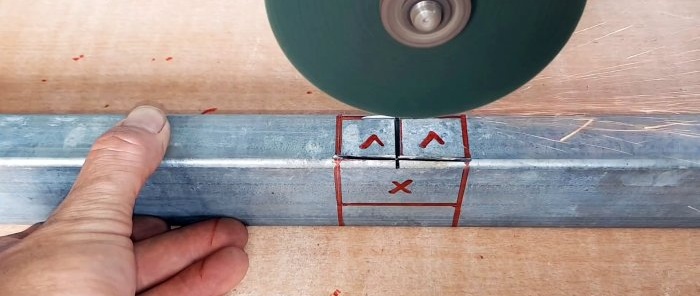

On the side where the second profile pipe is connected, you need to divide the contact side between the lines into 2 halves. Next, you need to cut the pipe according to the marks. On the joining side, the ribs and the central transverse line are cut. From the sides you need to completely remove the marked large rectangles.

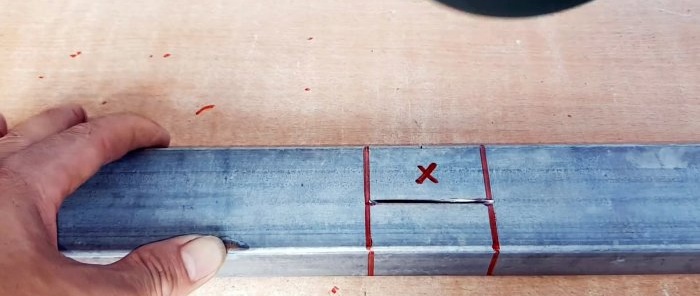

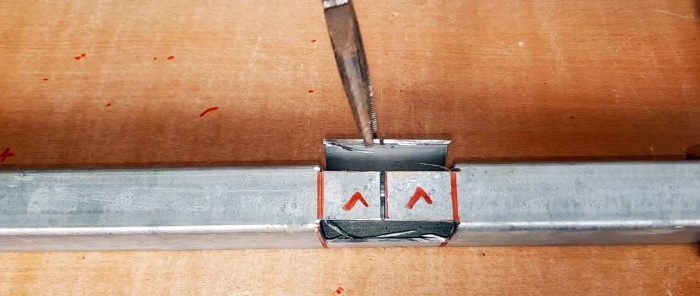

Next, the halves of the pipe wall from the joining side are bent outward at a right angle.

Holes are drilled in the eyes.

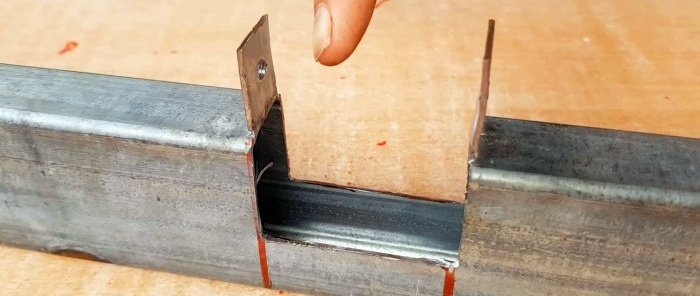

The ribs at the end of the tube need to be trimmed for docking. This will allow you to narrow it by tapping it on top with a hammer.

The adjacent tube, narrowed at the edge, is driven with a hammer into the socket cut out for it. Then you need to screw the metal screws into the side eyes and the double walls at the bottom of the connection.

As a result, this will give rigidity and strength no worse than welding.

Watch the video

Similar master classes