How to make a powerful cabbage shredder from a stepper tap

Fans of real homemade sauerkraut know well how difficult it is to chop it with a hand shredder. After shredding a whole bag, the hands simply fall off. Having made such a mechanical shredder, you can ferment cabbage in barrels without spending days on end processing it.

Materials:

- ball valve lever or metal strip;

- M10 pin;

- nuts, washers M6, M10;

- self-tapping screws;

- mounting corners – 2 pcs.;

- round door handle;

- plywood 12 mm;

- block 40x50 mm;

- Sheet steel;

- 1/2 inch copper tube;

- assembly knife blade.

Shredder manufacturing process

The assembly of the shredder begins with the manufacture of the rotation mechanism. The handle of a ball valve is used as its lever, but just a piece of strip will do. The antennae are cut off in it, a standard hole is drilled to 10 mm, and another 6 mm is drilled from the opposite edge.

The axis of the mechanism is made from a piece of M10 pin 30 cm long. You need to retreat 5 cm from the thread, sharpen the rest for a skewer, and sharpen the edge to the point.

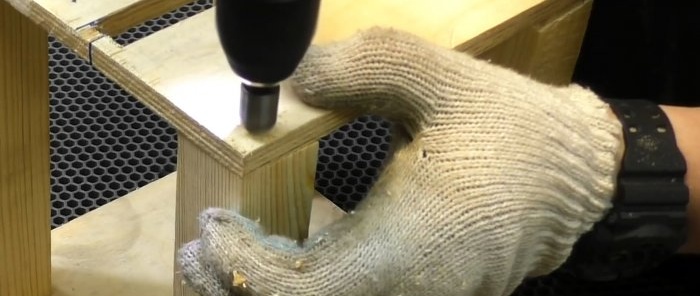

Next, you need to cut 2 mounting angles to fit the wedge.A hole is drilled into them on the whole side with a 10 mm drill.

A round door handle is inserted and tightened into the smaller hole of the faucet lever. In the larger one you need to insert a pin with a nut, washer and pointed corners directed towards the tip. It tightens securely on the lever.

2 pieces of 25x25 cm are cut out of plywood. You will also need 4 pieces of timber 22 cm each. You need to find the center on the plywood blanks. In one of them, an even cut 10 mm wide is made with a slight indentation from the center and edge.

A 40x40 mm plate is cut out of sheet metal. It is necessary to drill the center of a whole piece of plywood with a 12 mm drill bit. On one side, a plate is screwed on top of it with self-tapping screws. On the return side you need to press in a copper tube. It will be necessary to drill the plate so that it does not block the hole, but only supports the walls of the sleeve. The same tube is hammered into plywood with a cut.

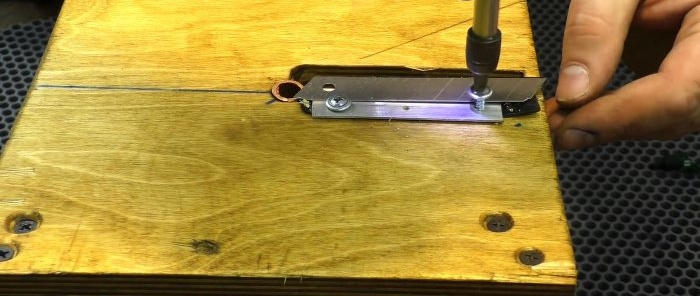

A table is screwed from plywood blanks and blocks using self-tapping screws. It needs to be sanded and soaked in vegetable oil. The blade of the mounting knife is pressed onto the metal strip substrate over the cut with the heads of the self-tapping screws.

Next, all that remains is to trim the head of cabbage and pierce it with a pick so that the wedges of the corners fit into it.

Then the pin is inserted into the table and rotated by the handle.

As you chop, the peak will lower, so you will need to make a hole on the base where the table is. Thus, in 1-2 minutes you can chop a head of cabbage.