Do-it-yourself powerful cordless drill made from PVC pipe

An electric drill and drill are available in most home workshops and garages. Both tools have disadvantages. They need 220 V alternating current. Small parts cannot be processed with a drill. The drill has low productivity. A homemade powerful drill or mini-drill powered by batteries will come to the rescue. It is more productive than a conventional engraver, smaller than a drill, runs on a pair of batteries - you can work away from a power outlet.

Materials used

To assemble the drill you will need the following components:- 18650 batteries - http://alii.pub/5becfz

- Electric motor 480 series - http://alii.pub/5x87cy

- Adapter for jaw chuck JT0 - http://alii.pub/5x87f3

- Mini drill chuck JT0 - http://alii.pub/5x87f3

- Box for 18650 batteries - http://alii.pub/5x87rc

- A pair of battery fuses - http://alii.pub/5x87h1

- Rocker switch - http://alii.pub/5x87m3

- Digital voltmeter - http://alii.pub/5x87l4

- Charger for 18650 batteries - http://alii.pub/5x87o1

- PVC pipe with a diameter of 35 mm.

Manufacturing process

In a pipe 100 mm long, a part of the wall is cut along the length to install the motor. Instead of a saw, you can use a soldering iron.

A pipe plug is cut out of a piece of plywood and painted. Two rectangular holes are made in it for a voltmeter with a power button.

Wires are soldered to the button and voltmeter. The button and dial are inserted into the plywood and it is glued to the pipe.

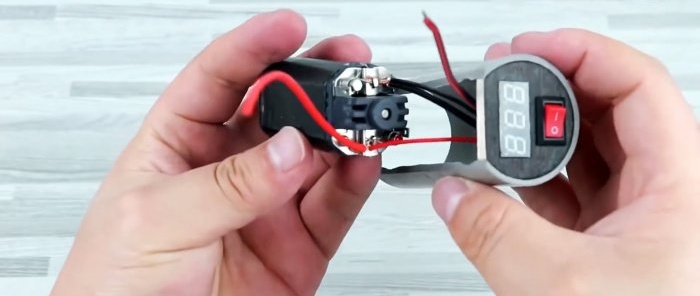

A pair of holes are made in the pipe to improve cooling of the electric motor. The engine is connected to a voltmeter and a toggle switch.

The motor is glued to the PVC body.

Electronic battery protection is soldered to the contacts of the battery box.

The circuits are connected in series and connected to the pins.

The contacts are sealed with a glue gun. The pipe is glued to the battery holder.

The mini-chuck is mounted on the electric motor shaft through an adapter.

The batteries are installed and the device is tested.

After a successful start, you can clamp a miniature drill attachment into the chuck and grind, cut, polish, and drill.

The device works properly with a flexible sleeve for the engraver, which will make the operation of the tool more convenient and expand its capabilities: access to small cavities, performing delicate work. It will also protect the engine from dust entering through the ventilation holes.

To charge the batteries, they are removed and installed in the charger.

Next, the universal drill is again ready for long-term use.

Watch the video

Similar master classes