How to make a drive for pumping a hydraulic jack from a screwdriver

The vast majority of car enthusiasts use bottle hydraulic jacks. They are reliable, compact, have a large load capacity, but are slow. To lift the car, you have to swing the lever dozens, or even a hundred times. Having modified the jack in the proposed way, you will be able to lift it using a cordless screwdriver in 5 seconds.

Materials:

- Bearing;

- wide nuts M10 – 2 pcs.;

- M10 bolt or stud;

- mounting bracket;

- bolts and nuts – M4.

Hydraulic Jack Upgrade Process

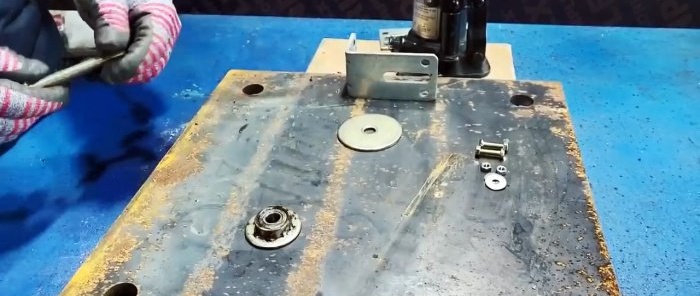

To remake the jack, you need to assemble the crank mechanism. To do this, a bearing is welded to a wide washer.

The second part of the mechanism is also made from a wide washer. It must be welded onto a bolt or stud. If a bolt is used, its head must be cut off.

In the washer welded to the bolt, a hole is visible through which an M4 screw is inserted and tightened with a nut. You need to place a narrow washer on the bolt itself so that when mating it rests against the inner race of the bearing of the first part.

These parts are installed on the mounting bracket.

It must be placed on the base of the jack, and then connected with a connecting rod made of sheet steel, a washer on a bolt with the jack lever. Cut off the rivet.

We install the connecting rod.

The height of the mechanism is adjusted relative to the length of the connecting rod, after which the shaft is finally fixed on the angle. The excess is cut off and the mechanism is welded to the base of the jack.

For convenience, you can weld a bit shank onto the shaft to make it easier to connect with a drill chuck.

Now the jack with the help of a screwdriver can lift the car in 5 seconds.

Watch the video

Similar master classes