How to make a jig for a router for a dovetail box joint

The tongue-and-groove box corner joint is neat and reliable. But it can also be made more powerful if you prepare the grooves with a dovetail router. To do this, you will need to assemble a special conductor.

Materials:

- 6 mm plywood or laminate scraps;

- plywood 18-20 mm or MDF;

- rail 15x30 mm;

- self-tapping screws

Conductor manufacturing process

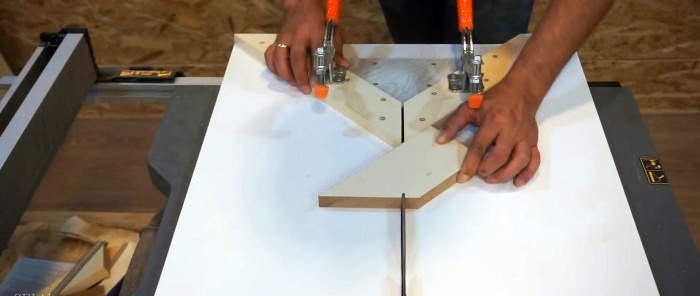

From thin plywood or laminate we cut out the sole of the conductor measuring 15x25 cm. We screw slats to it along the edges.

Mark a transverse line in the center of the workpiece. Then we glue V-shaped stops on it from thick plywood or MDF. They consist of 2 segments with ends sawn at 45 degrees. On the reverse side, the workpieces are additionally strengthened with self-tapping screws.

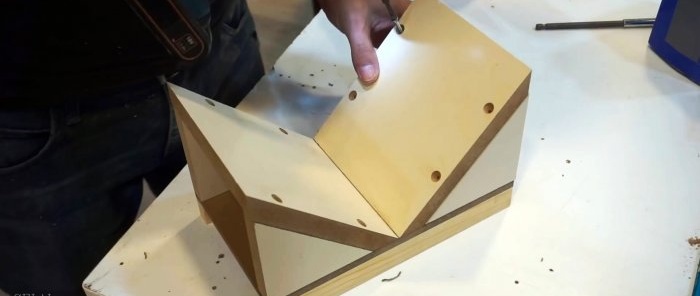

To ensure rigidity, the supports need to be strengthened by installing gussets made of the same material. The connections are similarly tightened with self-tapping screws, the heads of which must be recessed.

The conductor will additionally need 2 bar attachments, equal in length to its sole. A quarter is chosen from them.Then we mill a wide groove in the sole of the jig.

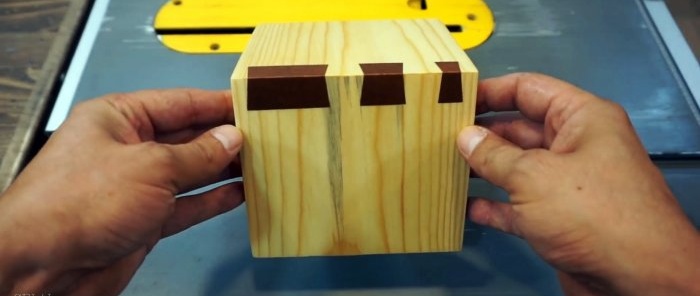

To make a corner box joint, you need to saw the workpieces at 45 degrees.

Then they are glued together at right angles.

After the glue has set, we apply a jig with a dovetail cutter to them, and mill the groove.

If you use attachments from a block, then it can be made narrower.

Next, we open the rail on the circular saw to get a tenon for the selected width of the groove on the box.

After that, we drive it in and cut it down.

The ends of the tenon are finished by grinding.