How to make a device for cutting pipe saddles from junk cars

Some used auto parts almost never lose their dimensional accuracy. We use this factor to make a useful tool for cutting the edges of round pipes and then joining them at various angles.

Will need

Materials:- used pistons and shock absorber;

- used corner and channel;

- metal plate;

- spray paint;

- bolts, nuts, wing nuts, washers;

- core drill;

- clamp;

- round steel pipe.

High-quality drills on AliExpress at a discount - http://alii.pub/5zwmxz

Tools: pendulum band saw, grinder, milling, lathe and drilling machines, welding, grinder, die, drill, measuring and marking tools, etc.The process of making tools from auto parts

We select two old pistons with hole diameters for the piston pins close to the diameter of the shock absorber rod.

We cut two identical strips from the steel corner shelves and mill them on all sides to dimensions of 65x250 mm.

We cut the shock absorber body at the top, pull out the piston rod from it, wipe it dry and measure the diameter to be 22 mm.

We measure the diameters of the holes for the fingers in the pistons, which turned out to be equal to 20.32 mm and 22.08 mm, which we select for further use.

We remove the thread from the rod and cut a new one to the required size, grind one side at a certain length to a smaller diameter.

We round and grind both plates obtained from the angle shelves from one edge.

At the base of the rounding we drill in the center of the hole.

At the bottom of the selected piston we draw a diameter perpendicular to the axis of the piston holes. We measure 20.27 mm in diameter from the ends and drill holes.

On one plate we draw lines parallel to the long sides so that the distance between them is 20.27 mm.

We drill on the lines, stepping back an equal distance from the edge of the plate, one hole at a time, then two more at a given distance from the first.

On a milling machine, we make slots in the longitudinal direction between these holes with a width equal to the diameter of the holes.

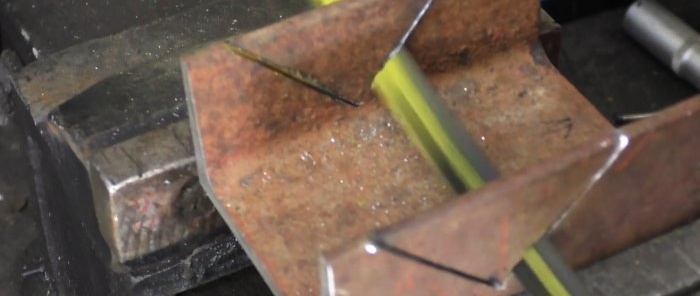

We cut off a fragment from the channel, install it with its back lengthwise on a plate without slots and lay the plate with slots, aligning the holes on which we place the piston.

We insert the shock absorber rod into the piston, sharpening one end. Holding the piston on the plate, rotate it around a vertical axis until horizontal lines appear on the channel legs.

Based on these lines, we cut out notches in the channel legs at an angle of 90 degrees to their entire height. Use a grinder to round the edges and corners and remove rust.

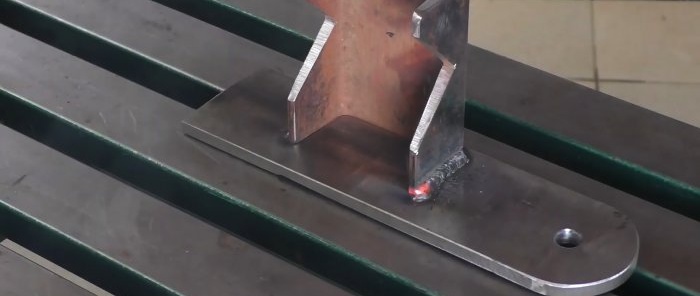

We weld a steel strip “on edge” longitudinally to the plate without slots, slightly retreating from the flat end.On the other side of the plate, we weld a vertical channel with recesses in the legs, but offset to the flat side. We paint the welded assembly and the plate with the slots.

We connect two identical bolts by welding the heads with a third one so that they are parallel to each other and directed in the same direction. We insert the bolts with washers into the holes in the piston from the inside.

We put a plate with slots on the rods of the bolts protruding from the bottom of the piston and secure them with wing nuts and washers.

We insert the shock absorber rod into the holes of the piston and screw and tighten the core drill onto the threads.

We connect the plates through the holes with bolts, washers and nuts. In principle, our device is ready for use.

We fix the device in a vice. We rotate the upper plate relative to the lower one at the required angle and tighten the coupling bolt with wrenches.

We secure the round pipe with a clamp in the grooves of the channel. We turn on the drill with a shock absorber and a core drill clamped in its chuck. We feed the drill forward, and the drill forms the edge of the pipe.

By changing the position of the plates relative to each other, we can prepare the edges of the pipes for connection at any angle.

Watch the video

Similar master classes