How to make a board without iron, heat and photoresist

Every electronics engineer is familiar with laser ironing technology (LIT) for the manufacture of circuit boards. It is accessible, does not require expensive equipment (if you do not take into account a laser printer) and rare reagents, so it legitimately deserves first place among other methods. Despite the fact that LUT has been used for more than 10 years, it can still be improved and simplified.

The fact is that when making boards, it is very important to choose the right iron temperature, pressing force and heating time. Not everyone succeeds the first time.

Let's look at a method that seems simpler, in which you don't need to use an iron or heat at all. No, this is a technology without the use of photoresist, as some might think at first.

Will need

- Alcohol.

- Acetone.

Manufacturing a circuit board without heating

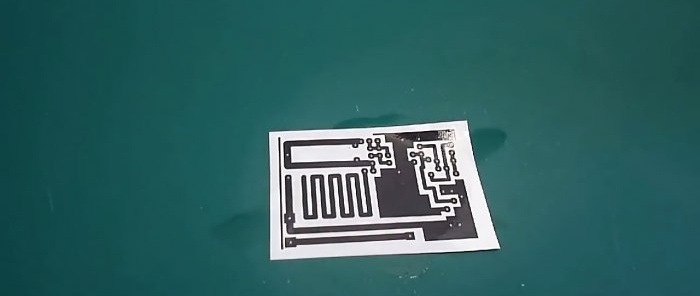

Everything is done the same way as in LUT. We print the board on a laser printer.

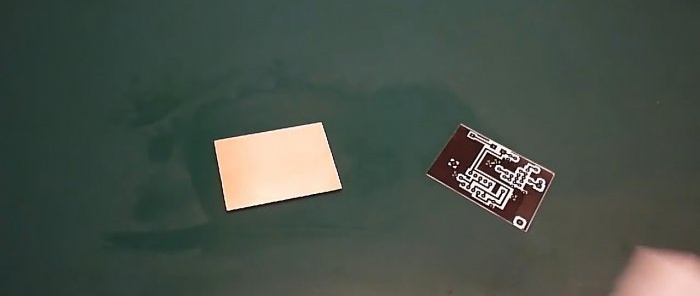

Next, we thoroughly wipe the board, previously sanded with a metal sponge, and the printed drawing with alcohol.

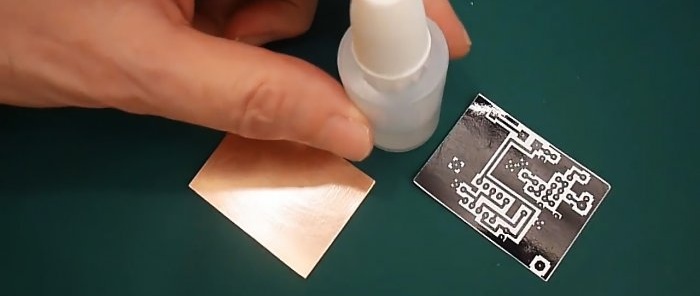

Before this, it is necessary to prepare a special alcohol-acetone solution.Mix 8 parts alcohol and 3 parts acetone. Pour everything into a convenient bottle.

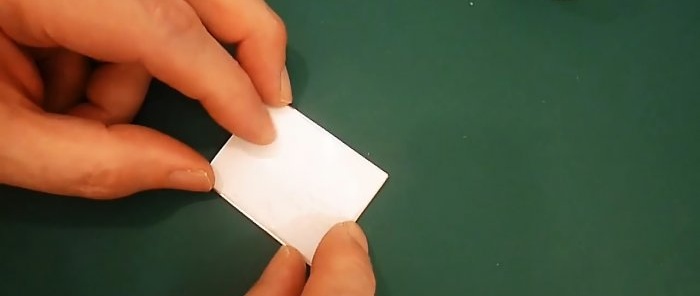

Now we squeeze the composition out of the bottle onto the textolite. We put the printout on top in ink to the board. We press with our hands.

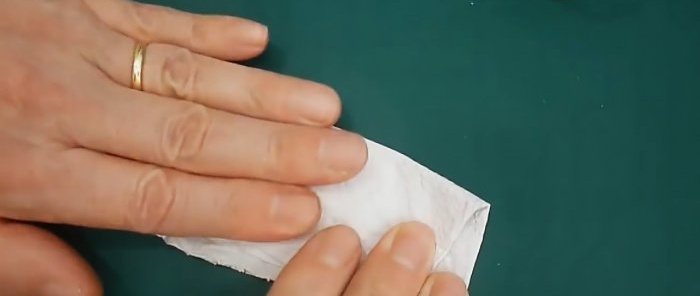

Use a napkin to remove the solution that has squeezed out on the sides.

Let it dry for about 5 minutes. Acetone dissolves the ink and it easily sticks to cleaned copper.

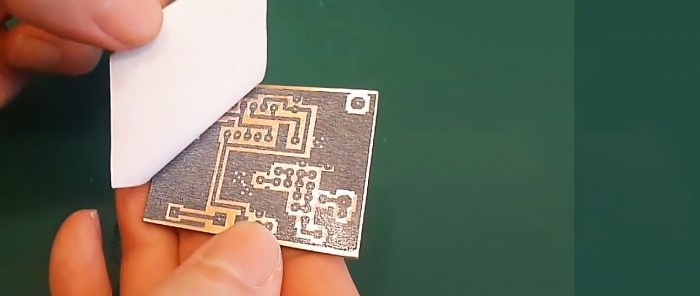

Next, soak the future board in water.

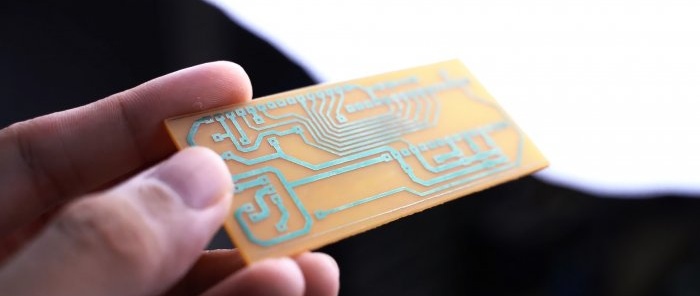

And after that the paper is easily removed.

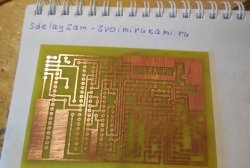

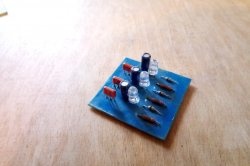

That's all the improvement. Looks like this could be useful to a lot of people.

Well, I don’t think it’s worth talking about etching. Read everything about the full LUT process here - https://home.washerhouse.com/en/662-tehnologiya-lut.html.