How to make a simple and reliable door latch from leftover metal

A garage, country house, barn or tool cabinet must be closed so that unauthorized people cannot enter or open it. Of course, door latches can be purchased at the store, but why spend money when you can make them yourself from leftover sheet metal that is no longer good for anything.

Will need

Materials:- a metal sheet;

- round steel bar;

- wire rod;

- bolt and nut;

- screws.

Long-lasting discs for angle grinders on AliExpress at a discount - http://alii.pub/61bjly

Tools: hammer, ruler and marker, pliers, vice, welding machine, drill, tap, grinder, core.The process of making a door latch with your own hands

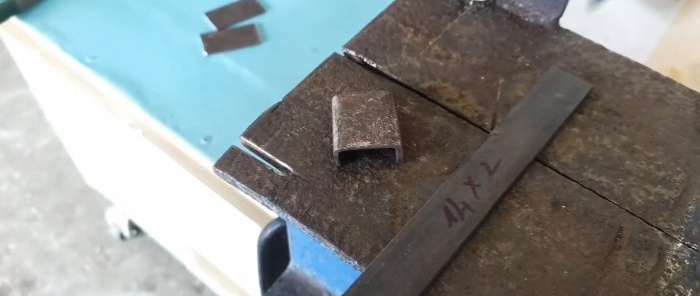

From a metal sheet we cut out a strip of 140×20 mm, a plate of 120×50 mm, a square of 50×50 mm and three identical plates of approximately 20×30 mm, the ends of which we bend 90 degrees to one side of such a length that it can move between them without jamming strip 20 mm wide.

We shorten the bent edges of the three plates to a strip thickness of 140×20 mm and get a kind of staples.

We lay a 140x20 mm strip on a 120x50 mm plate in the center in the longitudinal direction. We place a cardboard strip less than 20 mm wide on top of the steel strip. Place a bracket on top across the steel and cardboard strips, aligning its edge with the edge of the plate, and weld it.

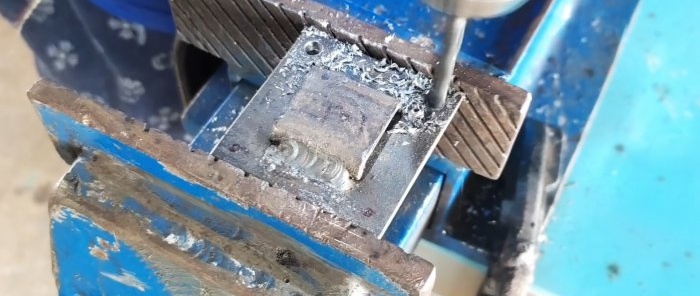

We cut a 20 mm high roller from a rod with a diameter of 15 mm. On its side surface, offset to one edge, we drill a through hole.

High-quality drills on AliExpress at a discount - http://alii.pub/5zwmxz

We make a ring from wire rod or thick wire on a device in the form of a rotating stepped cylinder, and put a roller on one of the separated ends and bring them together in the transverse and longitudinal directions.

We place the second bracket on the plate, aligning it with the free edge, insert a strip into it, apply the base of the roller with the ring to the strip in the middle, trace it with a marker and drill a hole slightly smaller than the marking. We apply the strip with the hole to the top of the roller and weld it.

We weld the second bracket to the plate, like the first, by first placing the same cardboard strip.

We place a steel square next to the plate, move the strip along the staples in its direction and place the third staple in the center on top of the strip. In the bracket farthest from the square, drill a through hole, including a strip and a plate. We cut the thread with a tap and screw in the bolt and nut under the head.

Using a drill and grinder, grind the hexagonal head of the bolt and nut to a cylindrical shape. We cut the bolt rod from the back side to the plane of the plate.

We drill holes in the plate and square in the corners, drilling out the front side and fasten the plate to the door leaf, and the square at the same level to the jamb using screws.

To fix the valve in the closed position, screw in the bolt and stop the movement of the moving element (valve).

A simple door latch is ready to use.

Watch the video

Similar master classes