How to make a pneumatic plug for temporarily plugging a pipe and working under pressure

Sometimes it is necessary to repair a pipeline under pressure, the water in which cannot be turned off due to lack of access to the tap, or if it is broken. In this case, a pneumatic plug will come to the rescue. It is placed in the pipe, and then expands to completely block the passage. In this case, the device does not interfere with work with the pipe.

Materials:

- Camera valve;

- copper tube 6 mm;

- tubular tourniquet;

- nylon ties.

Pneumatic plug manufacturing process

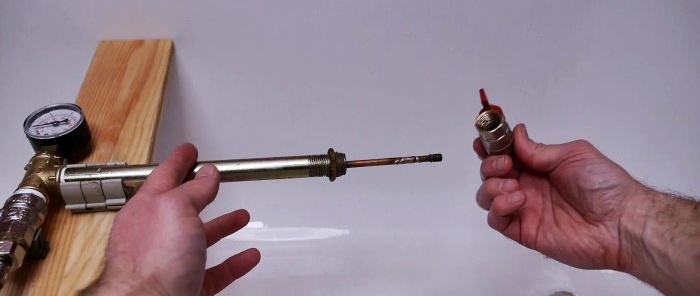

To inflate the plug you will need a valve from the chamber. The rubber needs to be removed from it.

If it is not cut, it can be burned with a torch.

Next, take a copper tube 25-30 cm long and squeeze its edge with pliers.

Then you need to solder it.

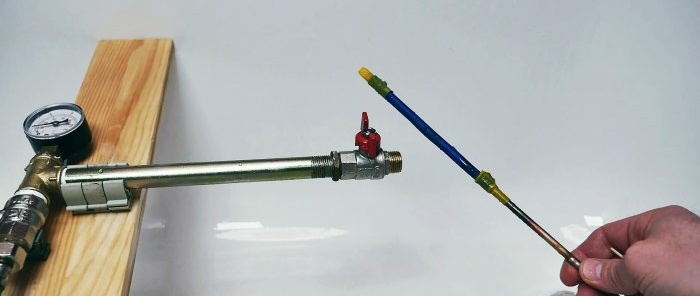

You need to solder a valve to the second edge of the tube, having first unscrewed the spool. Ideally, expand the tube so that the valve fits into it. After that, screw in the spool and pump it up with pressure.

You need to check the tightness of the soldering.

Now you need to drill the tube closer to the plugged edge.

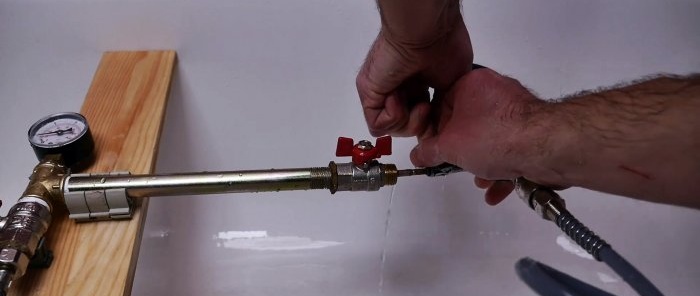

After this, a tubular tourniquet is pulled over it to block the hole. Then it is tightened with ties.

After this, when pumping the tube, the tourniquet will swell.

The device is placed in a pipe and air is pumped into it. The tourniquet expands and blocks the water, stopping the flow completely. At the same time, since the device is thin, it will not interfere with screwing on various fittings and taps, or cutting threads.

Watch the video

Similar master classes

Particularly interesting