How to make a high-altitude hedge trimmer from a grinder gearbox and a screwdriver

In order to remove excess and dry branches from trees with hand pruners, you need a ladder or stepladder, as well as a lot of time and physical effort. By taking a working gearbox from an old grinder, you can make a mechanized hedge trimmer, which will save time, effort and ensure safe work, since you won’t have to climb trees or climb a stepladder.

Will need

Materials:

- round metal rod with external thread;

- hexagonal socket head with connecting square;

- metal strip;

- gearbox from an old grinder;

- plastic pipe;

- regular nut;

- cutting metal disc.

Tools: vice, hacksaw, file, hammer, measuring and marking tools, grinder, drill, gas torch, round smooth rod, metal worm clamp, etc.

The process of transforming an angle grinder into a mechanized pruner-brush cutter for wood

Use a hacksaw to cut a piece 130 cm long from a round steel rod with an external thread.

At one end, using a hand metal file, we form a small section of square cross-section, corresponding in size and shape to the connecting square of the socket head.

We cut three fragments from the metal plate in which we drill holes and bend them in the middle in the form of rectangular staples.

We form a hexagon at the end of the angle grinder input shaft, corresponding to the hexagon of the socket head.

High-quality and durable drills on AliExpress at a discount - http://alii.pub/5zwmxz

We heat the end of the plastic pipe until it softens and put it on the belt of the drill body. Having retreated the calculated distance from the socket of the pipe, we drill a hole in its wall, under which we place a nut from the inside, temporarily glued to the end of the metal rod. Holding the nut with a rod coaxially with the hole, screw the side handle of the grinder into it from the outside of the pipe.

We insert a threaded rod with a socket head into the pipe from the socket side. We clamp its end into the drill chuck. We put the bell on the annular belt of the drill body and tighten it with a worm clamp.

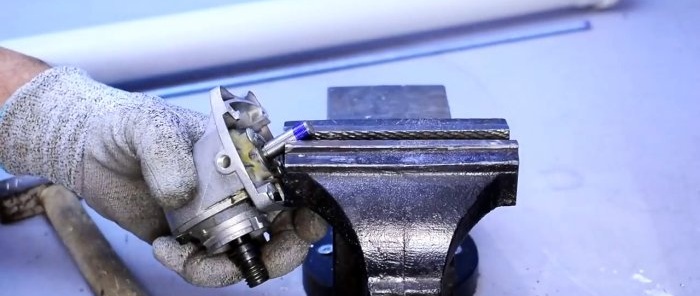

We insert the end of the input shaft into the hexagon of the socket head from the open side of the pipe and secure the grinder gear housing to the socket of the plastic pipe, using the brackets previously prepared from a metal plate.

We attach a cutting metal disk to the output shaft of the grinder gearbox. We turn on the drill and make sure that the disk rotates and it is ready to work on removing twigs and branches from trees while standing on the ground.

Long-lasting discs for angle grinders on AliExpress at a discount - http://alii.pub/61bjly

Watch the video

Similar master classes