How to make an off-road electric scooter based on a children's bicycle

With the advent of lithium-ion batteries, electric vehicles have become very popular. It is quiet, lightweight and very cheap to maintain. The only problem is that the price for such a scooter or bicycle is not at all small. However, if you purchase the necessary parts separately, it will be much cheaper to make your own electric vehicle. This is especially true for electric scooters.

Materials:

- Children bicycle;

- electric motor - http://alii.pub/5xzq4v

- profile pipe 20x40 mm, 40x80 mm

- steel strip 12x40 mm;

- pipe 12-16 mm;

- sheet metal 2 mm;

- ignition switch for electric scooter;

- battery case 36 Volt - http://alii.pub/5xzqgj

- wires;

- controller - http://alii.pub/5xzr4n

- gas lever - http://alii.pub/5xzr4n

- dye.

The process of making an electric scooter from an unwanted bicycle

First of all, remove the rear wheel of the bicycle and cut off the front fork from the frame.

Then we weld the frame of the foot platform from the profile pipe. Make its length convenient for yourself, but preferably no more than 80-100 cm, so as not to lose maneuverability. Be sure to weld several jumpers into the frame.

Next you need to tackle the rear fork. To do this, we cut out two blanks from a profile pipe with a tooth at the end in order to have a large area for welding to the frame. We make the tooth at an angle to shift the center of gravity of the scooter down. That is, the wheel axis will be higher than the platform. We weld the strips to these blanks.

Now we weld the fork blanks to the frame. Then we cut grooves in the strips for attaching the wheel.

From a more powerful profile pipe you need to make a frame for attaching the front fork. We cut it at 45 degrees on one side. We weld the fork bushing to the beveled end. Then we weld the frame to the platform frame. There will be a serious load on this unit, so it needs to be strengthened with an additional stand, jib or gusset.

Next you need to start controlling the scooter. To do this, we cut off the standard bicycle handlebar. We weld an extension pipe to its upper part.

At the bottom we make a folding mechanism. To do this, we weld a U-shaped profile to the lower section. We already attach the extension cord to it with two pins. This way, you can fold the handlebars for compact storage of the scooter.

We cut out the bottom from moisture-resistant plywood onto the frame of the scooter platform. Then we weld the bicycle arch with the brake mount to the frame. Immediately install the engine on the bracket, wheel, and tension the chain.

Please note that clamps cut from the strip are used to secure the rear wheel to the fork. With us it will definitely not fall out on the go.

After installing the brakes, we lay the cable to the steering wheel and install the lever. From sheet metal you need to make a platform for the legs, as well as a casing for the engine. They are welded together, then screwed onto the frame. After this, you need to weld the battery mount to the frame.

At this point, the welding work is completed, and you can proceed to painting.

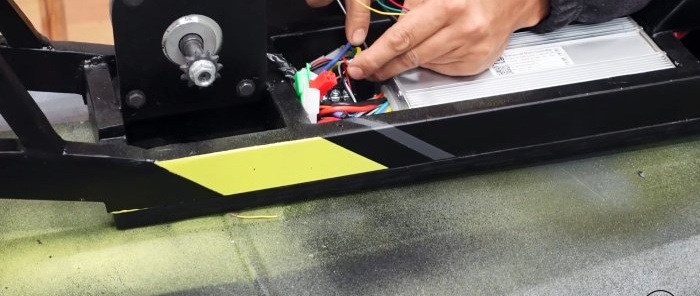

Next, we cut the ignition switch into the frame and lay the wiring to it. We install the engine, put the controller in the frame under the platform. According to his diagram, we connect the throttle, engine power, and wiring from the battery socket.

Then we close it all with a lid and glue anti-slip strips for the feet. Next, install the wheels, tighten the chain, and put the handles on the steering wheel. That's it, after installing the battery you can ride.

Worthy of attention: A scooter with a chainsaw engine and an angle grinder gearbox - https://home.washerhouse.com/en/6052-samokat-s-dvizhkom-benzopily-i-reduktorom-bolgarki.html

The scooter has excellent off-road qualities.

Watch the video

See all the assembly details in the video below.