5 reliable ways to connect PP pipes without a welding machine

Polypropylene pipes are simply a wonderful material for the quick construction of water communications. The only drawback is the inconvenience of welding: you need a specialized soldering iron that runs on mains power. And the main difficulty lies not in finding the welding tool itself, but rather in finding the electrical network to connect it. But there is a way out! Here are 5 ways to connect pipes very securely without welding. There are both collapsible and non-collapsible options.

1. How to make a thread on the end of a plastic pipe or fitting

At the end of a brass nipple with external thread fixed in a vice, we make 4 slots, evenly spaced around the circumference and at a certain angle.

We screw the end of the pipe or fitting onto the end with the slots and make an internal thread in them.

Now you can use FUM tape to screw them tightly and hermetically onto a tap, squeegee, etc.

2. How to connect a PP pipe with a metal union nut with a fitting

We heat the union nut with the fitting in the flame of a gas burner and quickly press the end of the plastic pipe to the end of the fitting screwed into the nut.

Cool the assembly in cold water, unscrew the fitting and unscrew the pipe with a ring edging formed at the end.

We put a nut on the free end of the plastic pipe and screw it onto the thread formed on the edging. We place a gasket on the edging in the nut and screw the lining into which you can then screw another pipe or fitting with a similar thread at the end.

3. How to connect plastic pipes of the same diameter with a short section of another pipe with a larger diameter

To connect plastic pipes with an outer diameter of 25 mm, we take a short piece of pipe with an inner diameter of 25 mm.

Lubricate the inside of the short piece of pipe on both sides with adhesive suitable for this case and insert the pipes to be connected into it until their ends meet inside the short tube. Once the glue has cured, the connection cannot be broken.

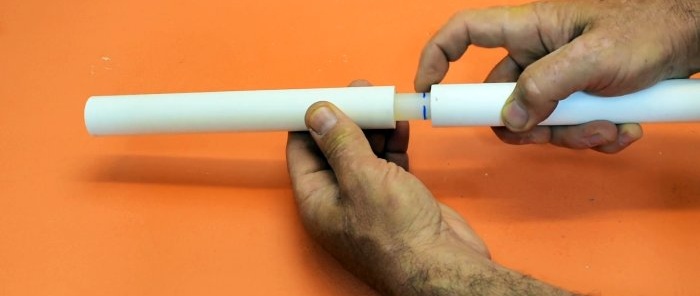

4. How to connect two PP pipes with a short section of another pipe of smaller diameter

To be specific, let’s connect two plastic pipes with outer and inner diameters of 25 and 16 mm, respectively, using a short pipe with an outer diameter of 16 mm.

Lubricate the inner sides of the pipes to be connected with a suitable glue on one side about half the length of the short tube. We put a mark in the middle of the short tube and put each of the connected pipes on the short one up to the mark. After 10 minutes the connection acquires the necessary strength.

5. How to securely fasten plastic pipes to a double-sided quick-release connector

We disassemble the connector and make sure that the round rubber o-rings are in order. Using a sharp knife, remove the circular chamfers from the outer edges of the pipes, lubricate them with oil, carefully insert them into the connector on both sides of the pipe and tighten the sealing nuts with wrenches.

Sealing is 100 percent guaranteed.

Watch the video

Similar master classes