Reliable dismountable connection of a profile pipe at right angles without welding

It is possible to assemble metal structures from profile pipes without using a welding machine. For this purpose, embedded elements and bolts are used, due to which such a connection is dismountable. In terms of reliability, it is not inferior to welding, and at the same time it is done with simple tools.

Materials:

- Profile pipes;

- bolts;

- nuts

High-quality drills on AliExpress at a discount - http://alii.pub/5zwmxz

The process of connecting pipes without welding

The secret to this connection is the use of mortgages. To manufacture them, you will need to select a profile tube of such a diameter that can fit tightly inside the main pipe used to assemble the structure.

A cube with equal sides is cut out of the smaller one.

A through hole is drilled in the mortgage with a slight offset from the center.

Then it is applied to the edge of any of the pipes being connected, and a mark for drilling is placed along its hole. It is necessary that the mortgage is located not reaching the edge and the sides to the thickness of the wall. The main pipe is drilled according to the mark.

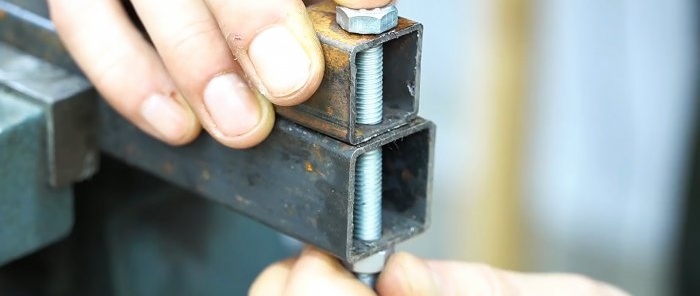

The mortgage is screwed to the pipe with a bolt and nut.

Then the second pipe is put on it. You need to set it at a right angle and secure it with a clamp or clamp. After this, it is drilled through with a slight offset from the center so as not to intersect with the tightened bolt.

Now all that remains is to secure the second pipe, and the corner joint is ready. Similarly, it is possible to make a T-shaped fastening.

The result is a reliable, collapsible structure that can be assembled in the absence of a welding machine or mounting angles.

Watch the video

Similar master classes