How to roll a pipe and make a beautiful tip using a lathe

On lathes, in addition to mechanical processing of mainly metal workpieces, many other operations can be performed, in particular, the process of end friction welding or pipe rolling using the thermomechanical method.

How to make a beautiful tip using a lathe

In both of these cases, the long-known process of converting kinetic or motive energy into its thermal form is used. It consists in the fact that when metal workpieces or parts rub against each other, their temperature rises and can first reach the point of plastic softening, and then even the melting point.

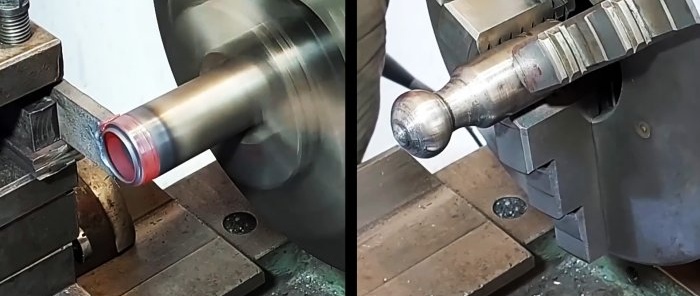

Let's try to use this technique for the process of rolling a round pipe. To do this, in the tool holder, instead of a conventional cutter, we fix a rigid plate made of heat-resistant steel with a semi-cylindrical recess at its working end, the diameter of which must coincide with the outer diameter of the round pipe that we are going to subject to the rolling process.

To prevent the end of a round pipe from beginning to deform under thermomechanical influence, before clamping it in the chuck of a lathe, we place a socket nut or something similar in it with a suitable diameter.

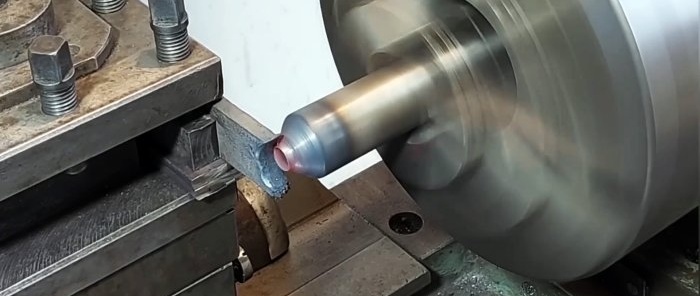

We bring the recess at the working end of the heat-resistant plate to the round pipe and turn on the transverse feed. After a short time, the metal of the pipe will begin to heat up intensely and turn red. In this case, a fairly significant softening of the pipe metal occurs.

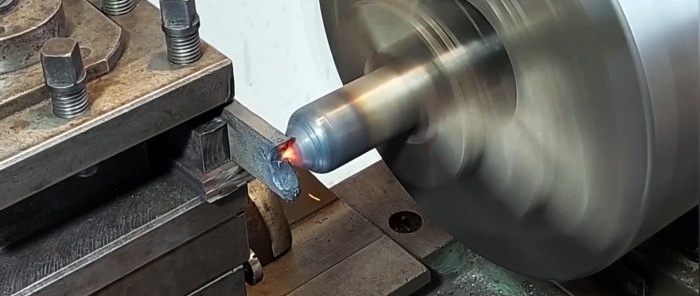

By combining the transverse and longitudinal feed of the caliper, we obtain a straight cone at the end of the pipe, which we gradually transform into an almost hemisphere. Then we rest the recess of the heat-resistant plate against the section of the pipe behind the end head and, also, by adjusting the transverse and longitudinal feed, we heat the metal red-hot and first form a cone, and then almost a hemisphere.

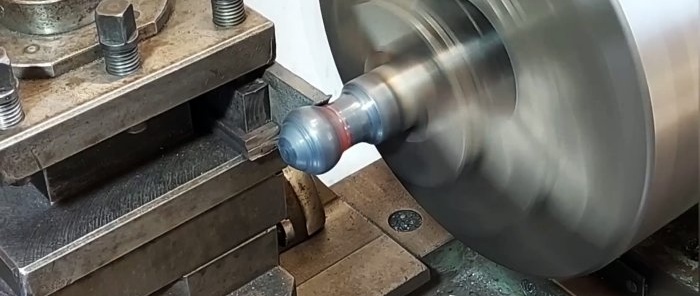

Further, continuing to influence the resulting profile thermally and mechanically, we achieve the ideally possible spheroidal shape. Let the metal cool, release it somewhat, and reinstall the pipe with a roughly formed spheroidal end.

Using a hand file, we remove the most noticeable marks, irregularities and burrs. Then we begin the sanding process using sandpaper with decreasing grit, first at low speeds and finish sanding the surface at maximum speed.