Shoe dryer

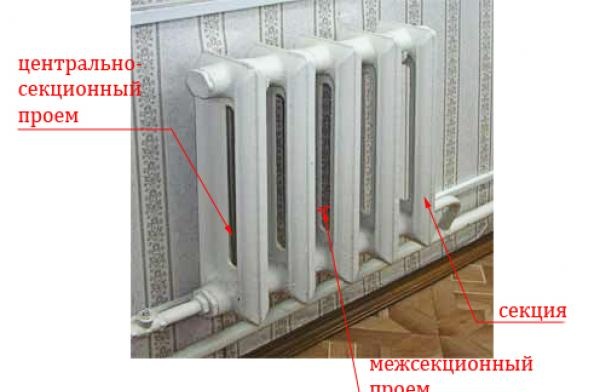

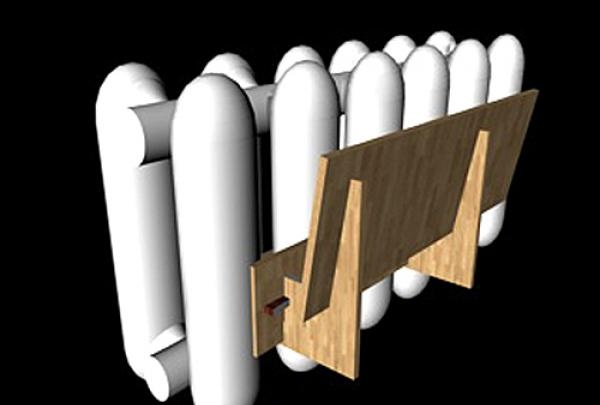

Everyone has faced the problem of drying shoes in winter. There are a lot of shoe dryers, but the most common is the central heating radiator.

The only question is how to install the shoes. I propose to make a dryer from the remains of the laminated floor (at the same time solving the issue of using scraps from laying the laminate). Advantages of this design: attached directly to the battery on the side, and not on top; the ability to mount one dryer over another (if there are two dryers), which saves space; It can be easily disassembled for the summer and takes up very little space when disassembled. Laminate cuttings 8 mm thick were used. To make it you will need:

- laminate residues;

- ruler, pencil;

- jigsaw;

- electric drill, drill with a diameter of 8 mm;

- emery cloth, file;

- varnish or paint, brush.

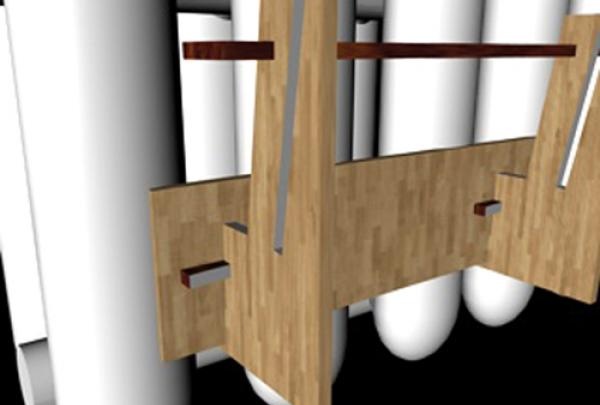

The dryer consists of two rack holders, an internal locking bar, an outer locking bar, two wedges and a stop screen.

To simplify assembly, the kit includes an auxiliary strip.

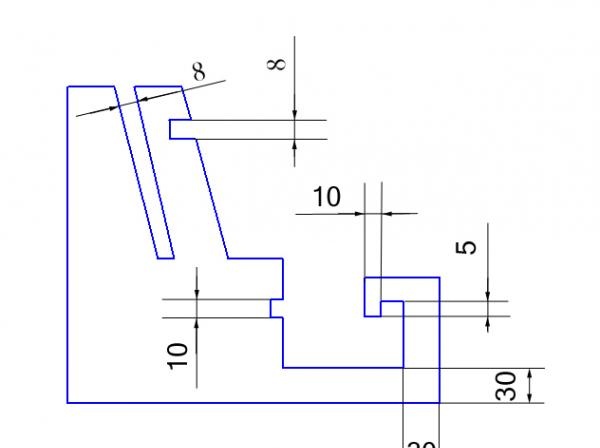

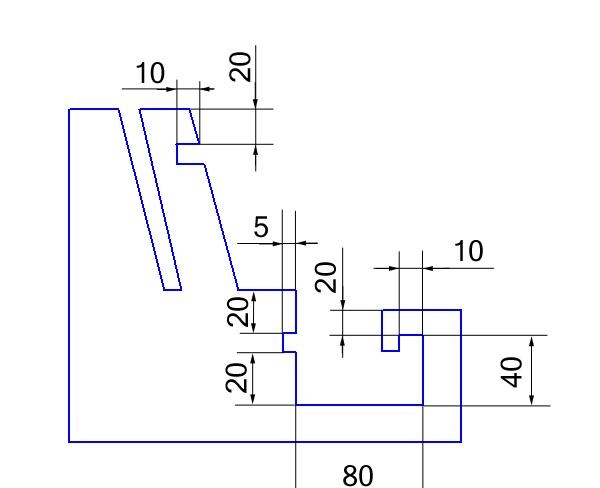

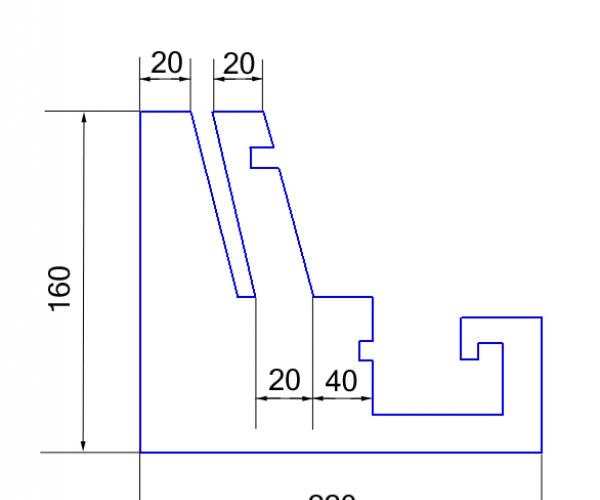

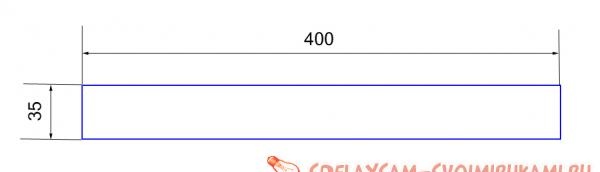

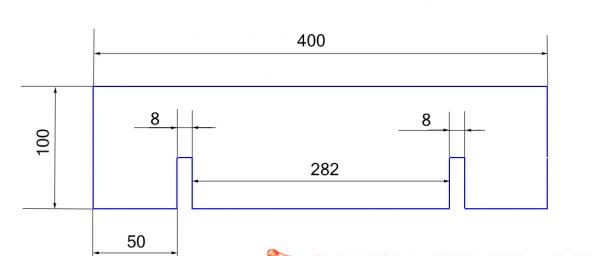

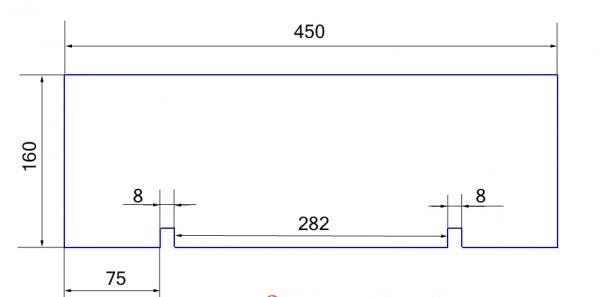

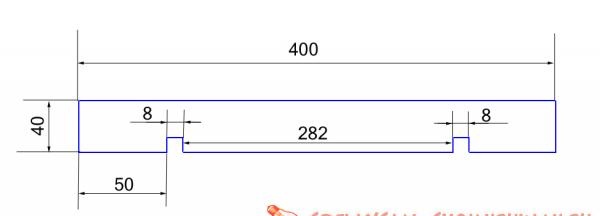

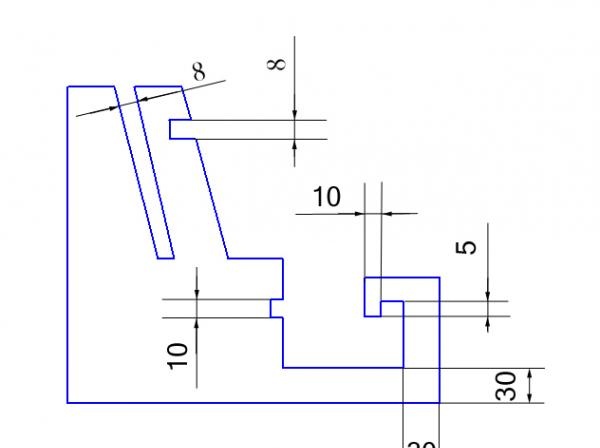

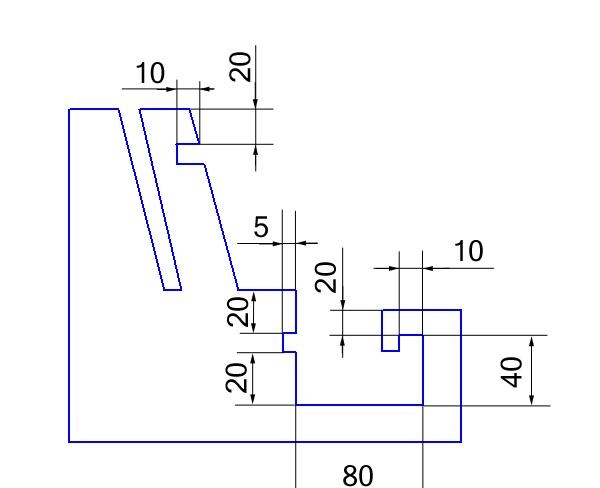

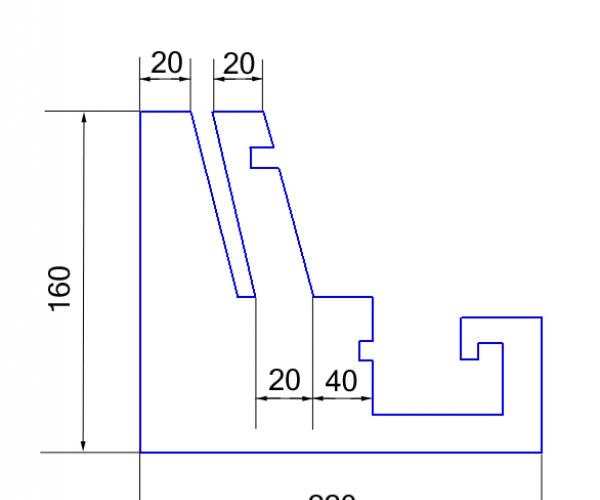

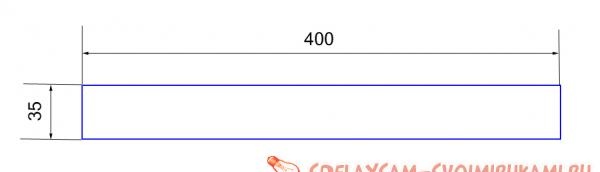

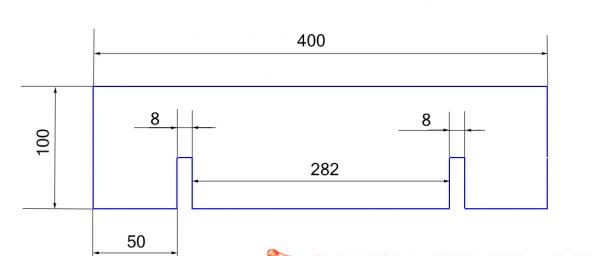

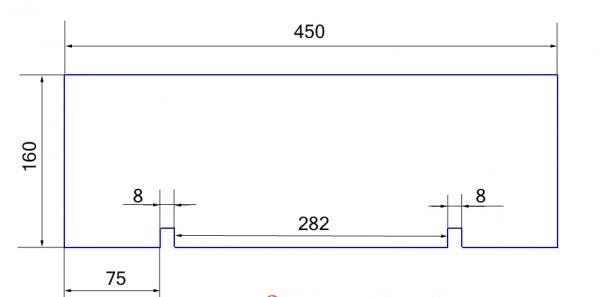

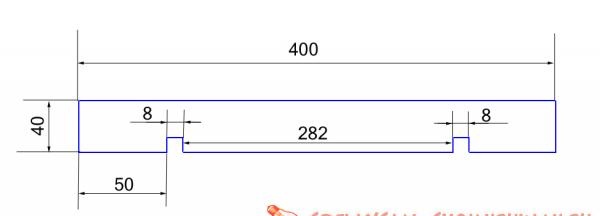

The support stand is the main structural element and has a complex configuration, so its dimensions are given in three figures so as not to clutter the drawing.The entire structure is assembled without the use of glue or other fastening devices, such as screws, etc. However, there are cross joints (half-wood overlay).

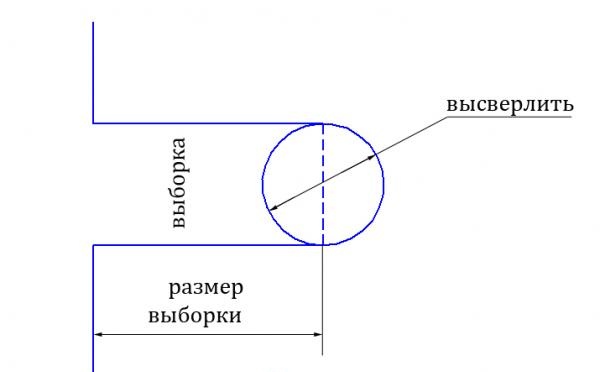

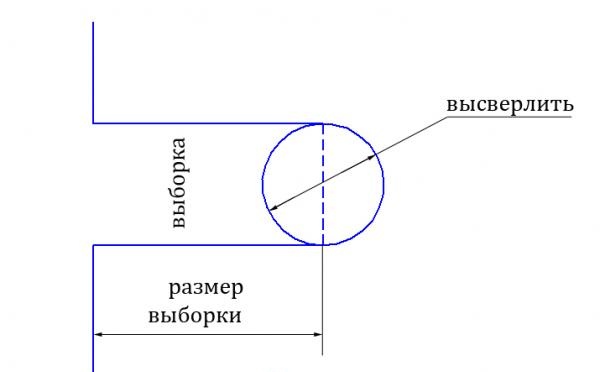

It's easy to do. We mark the sample in the right place. At the end of the sample, we drill a hole in the middle with a diameter of 8 mm - according to the thickness of the laminate. Using a jigsaw, we cut out a sample along the inside.

If necessary, adjust with a file.

The laminate has a durable waterproof coating on both sides, but cuts under the influence of water will swell and damage the structure. Therefore, all cuts must be painted over or varnished.

Since laminate fasteners do not play any role, we do not pay attention to them.

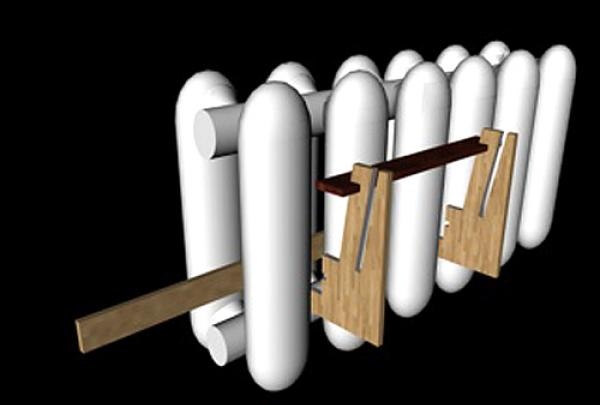

Let's start assembling. We connect the auxiliary strip to the racks.

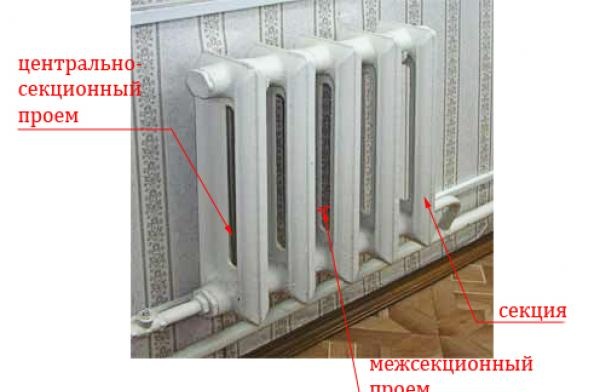

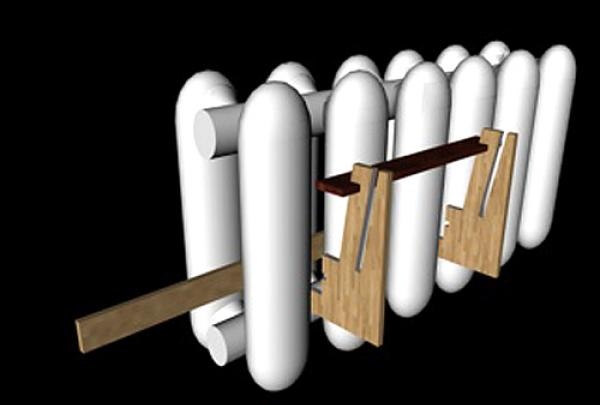

Holding the auxiliary bar with one hand, we push the lower C-shaped parts of the racks into the first and fourth intersection openings, counting from the edge. With the other hand, install the inner striker plate through the center sectional opening so that it fits into the C-shaped catch.

We pull it up by the auxiliary bar and install the outer locking bar on top.

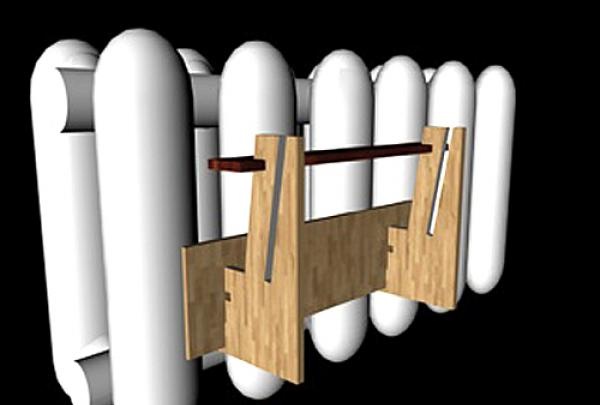

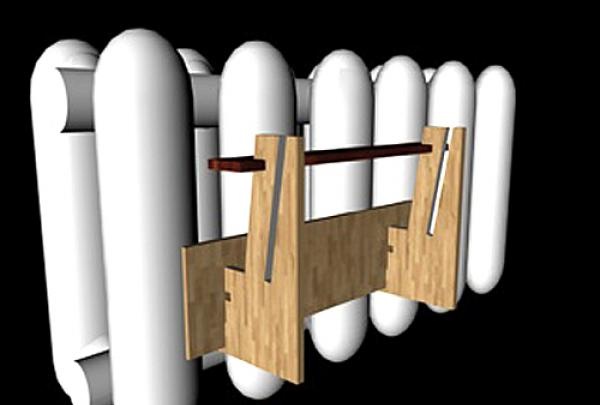

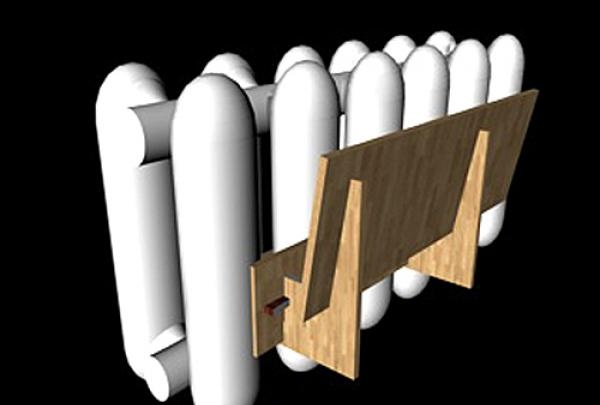

While the dryer is moving, we determine its place as desired using up and down movements. Installing wedges.

We remove the auxiliary bar. Insert the stop screen.

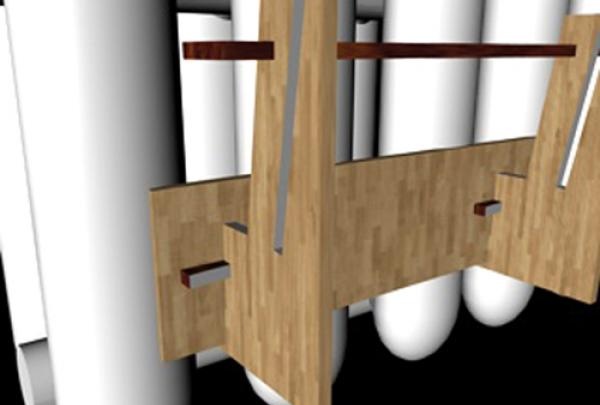

Between the screen and the battery there is a space where it is convenient to insert shoes with the toe down.

If it seems to you that the boot does not fit tightly to the battery, you can remove the screen and place it closer, resting it on the holders.

The only question is how to install the shoes. I propose to make a dryer from the remains of the laminated floor (at the same time solving the issue of using scraps from laying the laminate). Advantages of this design: attached directly to the battery on the side, and not on top; the ability to mount one dryer over another (if there are two dryers), which saves space; It can be easily disassembled for the summer and takes up very little space when disassembled. Laminate cuttings 8 mm thick were used. To make it you will need:

- laminate residues;

- ruler, pencil;

- jigsaw;

- electric drill, drill with a diameter of 8 mm;

- emery cloth, file;

- varnish or paint, brush.

The dryer consists of two rack holders, an internal locking bar, an outer locking bar, two wedges and a stop screen.

To simplify assembly, the kit includes an auxiliary strip.

The support stand is the main structural element and has a complex configuration, so its dimensions are given in three figures so as not to clutter the drawing.The entire structure is assembled without the use of glue or other fastening devices, such as screws, etc. However, there are cross joints (half-wood overlay).

It's easy to do. We mark the sample in the right place. At the end of the sample, we drill a hole in the middle with a diameter of 8 mm - according to the thickness of the laminate. Using a jigsaw, we cut out a sample along the inside.

If necessary, adjust with a file.

The laminate has a durable waterproof coating on both sides, but cuts under the influence of water will swell and damage the structure. Therefore, all cuts must be painted over or varnished.

Since laminate fasteners do not play any role, we do not pay attention to them.

Let's start assembling. We connect the auxiliary strip to the racks.

Holding the auxiliary bar with one hand, we push the lower C-shaped parts of the racks into the first and fourth intersection openings, counting from the edge. With the other hand, install the inner striker plate through the center sectional opening so that it fits into the C-shaped catch.

We pull it up by the auxiliary bar and install the outer locking bar on top.

While the dryer is moving, we determine its place as desired using up and down movements. Installing wedges.

We remove the auxiliary bar. Insert the stop screen.

Between the screen and the battery there is a space where it is convenient to insert shoes with the toe down.

If it seems to you that the boot does not fit tightly to the battery, you can remove the screen and place it closer, resting it on the holders.

Similar master classes

Particularly interesting

Comments (0)