Mini vacuum cleaner from an old hair dryer

A hair dryer breaking down is quite a rare case, since there is nothing special to break; it consists of a plastic case, a motor with a propeller, a heating element made of a nichrome spiral, and a switch. Well, a couple of screws. And they change the hair dryer by buying a new one, due to the usual obsolescence of the item. Tired of the old one. In a rare case, due to a breakdown. After purchasing a new hair dryer, the old hair dryer, as a rule, must be disposed of. But an old hair dryer can also be used. A rather unique application is to make a small vacuum cleaner out of it.

We are not talking about a powerful vacuum cleaner that can vacuum the entire apartment. It is more of a helper in the case, for example, when something has been spilled, and there is no desire to take out an ordinary, large vacuum cleaner. The motor inside the hair dryer runs at 9-12 volts. It is powerful enough to pick up even spilled rice grains, not to mention smaller debris. Also, such a miniature vacuum cleaner is very good and convenient for removing dust from indoor plants, small souvenirs, from the surface of a cabinet and other hard-to-reach places where it is difficult to reach with a regular vacuum cleaner. To build such a vacuum cleaner from an old hairdryer, you must first find out the breakdown, if any.For our homemade product, the most important thing is that this device has a working motor. The rest doesn’t matter - the rest will be deleted anyway...

First we need to disassemble the hair dryer, which we plan to convert into a vacuum cleaner. To do this, using a suitable screwdriver, release the mounting screws from the housing.

Next, we disassemble the body into parts and put it aside - while we work with the internal parts. Using wire cutters or pliers, remove the heat-resistant partitions with a nichrome spiral wound on them. If heat-resistant partitions may be useful in the future, then the spiral can be thrown into the trash without hesitation - it has most likely already outlived its usefulness... Next is the switch. The switch that was initially installed in the hair dryer body is not suitable for our purpose, because it has several modes. Namely; turning on, changing speeds, and turning off. We also remove it from the structure and put it away somewhere until required. In place of the remote switch, install a simple switch. The standard switch I have did not fit the body a little, so I had to modify the body with a burr using a machine with a cutting disc.

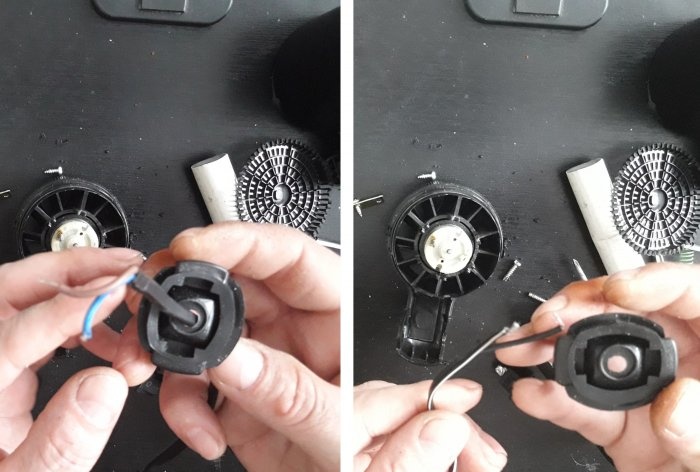

Using wire cutters, we also remove the resistors that are soldered to the contacts from the motor, since the motor will be powered directly from the 9-volt power supply.

Cut off the back grille of the hair dryer, on the side from which air will be drawn in.

In general, we cut out and bite off everything except the motor with the propeller attached to the body. Next, we take a 9-volt power supply (I have a removable battery, but you can use a regular one), and put a plastic plug from the hair dryer handle onto its two-wire cable.

We check the polarity of the motor and solder the power supply wires to the motor contacts.

Next, having estimated where the switch will be located approximately, we cut one of the power cords and solder the switch into the resulting gap.

We install the switch in its place in the housing, install the engine with the propeller in place, and then fasten the entire housing together using mounting screws.

For greater reliability, I added a couple more drops of glue, since the body of the hair dryer I had was quite flimsy.

Now it’s the turn of the top of the bottle.

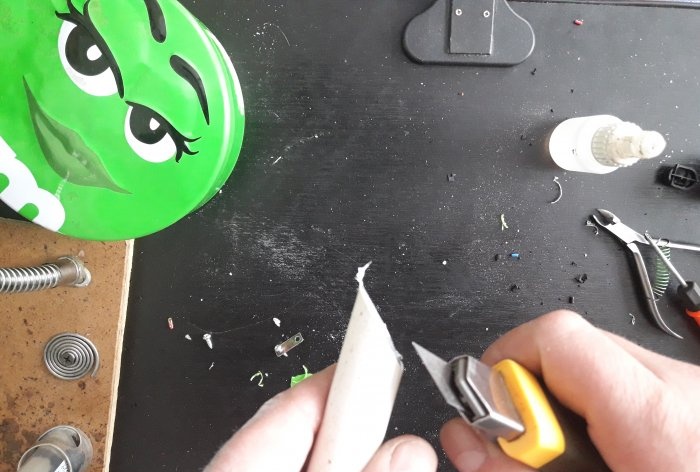

We cut off the neck so that it fits onto the round body of the hair dryer, in the part where air and debris will be sucked in in the future. We align it as evenly as possible and attach it to the body using instant glue and soda.

The main work is finished. All that remains is to assemble the nozzle for the resulting vacuum cleaner and a garbage bag. Making a thin nozzle takes just a few minutes! We cut a hole in the bottle cap for a piece of metal-plastic pipe.

We stick the pipe into the hole, secure it with glue and soda, and cut off the tip at an angle of 45 degrees.

Next, simply screw the nozzle onto the body, like a regular bottle cap.

Several such attachments can be made, in different shapes, for different purposes. Well, and now the bag.Instead of a bag, in fact, you can use anything. For example, a sleeve or a sock. But I couldn’t find where to trim the sleeve, and I didn’t think it was very aesthetically pleasing to use a sock, so I sewed the bag myself, from an unnecessary rag, in a couple of minutes.

Well, now we tear out the second, opposite grid from the hair dryer with pliers, and put a bag on this end.

The bag should fit tightly so that it does not get torn off by the air flow. You could probably even secure it with tape, although I didn’t. That's all. You can check.

You can see tests of the mini vacuum cleaner below, at the end of the video about the assembly of this device.

We are not talking about a powerful vacuum cleaner that can vacuum the entire apartment. It is more of a helper in the case, for example, when something has been spilled, and there is no desire to take out an ordinary, large vacuum cleaner. The motor inside the hair dryer runs at 9-12 volts. It is powerful enough to pick up even spilled rice grains, not to mention smaller debris. Also, such a miniature vacuum cleaner is very good and convenient for removing dust from indoor plants, small souvenirs, from the surface of a cabinet and other hard-to-reach places where it is difficult to reach with a regular vacuum cleaner. To build such a vacuum cleaner from an old hairdryer, you must first find out the breakdown, if any.For our homemade product, the most important thing is that this device has a working motor. The rest doesn’t matter - the rest will be deleted anyway...

Will need

- An old hair dryer (with a working motor!).

- Simple switch.

- 9 volt power supply.

- Top half of a plastic bottle (with neck and cap).

- Metal-plastic tube with a diameter of 20 mm (15-20 cm long).

- A small rag bag for the outer diameter of the hair dryer.

- Tools and consumables:

- Secondary glue and soda.

- Soldering iron, with flux and tin.

- Boring machine with cutting disc.

- Stationery knife.

- Scissors.

- Screwdriver.

- Marker.

- Pliers.

Making a mini vacuum cleaner with your own hands

First we need to disassemble the hair dryer, which we plan to convert into a vacuum cleaner. To do this, using a suitable screwdriver, release the mounting screws from the housing.

Next, we disassemble the body into parts and put it aside - while we work with the internal parts. Using wire cutters or pliers, remove the heat-resistant partitions with a nichrome spiral wound on them. If heat-resistant partitions may be useful in the future, then the spiral can be thrown into the trash without hesitation - it has most likely already outlived its usefulness... Next is the switch. The switch that was initially installed in the hair dryer body is not suitable for our purpose, because it has several modes. Namely; turning on, changing speeds, and turning off. We also remove it from the structure and put it away somewhere until required. In place of the remote switch, install a simple switch. The standard switch I have did not fit the body a little, so I had to modify the body with a burr using a machine with a cutting disc.

Using wire cutters, we also remove the resistors that are soldered to the contacts from the motor, since the motor will be powered directly from the 9-volt power supply.

Cut off the back grille of the hair dryer, on the side from which air will be drawn in.

In general, we cut out and bite off everything except the motor with the propeller attached to the body. Next, we take a 9-volt power supply (I have a removable battery, but you can use a regular one), and put a plastic plug from the hair dryer handle onto its two-wire cable.

We check the polarity of the motor and solder the power supply wires to the motor contacts.

Next, having estimated where the switch will be located approximately, we cut one of the power cords and solder the switch into the resulting gap.

We install the switch in its place in the housing, install the engine with the propeller in place, and then fasten the entire housing together using mounting screws.

For greater reliability, I added a couple more drops of glue, since the body of the hair dryer I had was quite flimsy.

Now it’s the turn of the top of the bottle.

We cut off the neck so that it fits onto the round body of the hair dryer, in the part where air and debris will be sucked in in the future. We align it as evenly as possible and attach it to the body using instant glue and soda.

The main work is finished. All that remains is to assemble the nozzle for the resulting vacuum cleaner and a garbage bag. Making a thin nozzle takes just a few minutes! We cut a hole in the bottle cap for a piece of metal-plastic pipe.

We stick the pipe into the hole, secure it with glue and soda, and cut off the tip at an angle of 45 degrees.

Next, simply screw the nozzle onto the body, like a regular bottle cap.

Several such attachments can be made, in different shapes, for different purposes. Well, and now the bag.Instead of a bag, in fact, you can use anything. For example, a sleeve or a sock. But I couldn’t find where to trim the sleeve, and I didn’t think it was very aesthetically pleasing to use a sock, so I sewed the bag myself, from an unnecessary rag, in a couple of minutes.

Well, now we tear out the second, opposite grid from the hair dryer with pliers, and put a bag on this end.

The bag should fit tightly so that it does not get torn off by the air flow. You could probably even secure it with tape, although I didn’t. That's all. You can check.

Watch the video

You can see tests of the mini vacuum cleaner below, at the end of the video about the assembly of this device.

Similar master classes

Particularly interesting

Comments (3)