How to make a complex sharpener for simple knife sharpening

Like all tools, knives require proper care, in particular, high-quality sharpening, in which it is very important to maintain a constant sharpening angle along the entire length of the blade.

Of course, this is not difficult for an experienced sharpener to achieve even when working manually. For everyone else, maintaining the required sharpening angle will be quite difficult. Will the problem of dull knives remain insoluble for them?

There are three ways out of this predicament: learn to sharpen knives, but this will require a lot of time, patience and effort; turn to a professional for help every time and pay for his expensive service; make your own knife sharpener and don’t worry about the sharpening angle.

Below we will consider a method for manufacturing a device for sharpening knives based on an electric sharpener with two abrasive wheels.

So that the work does not take a lot of effort and time, it is good to have in stock: a welding machine, machines (drilling, milling and turning), a pendulum saw, a drill, a grinder, wrenches, marking tools, etc.

In addition to the already mentioned electric sharpener, you need to stock up on materials and components:

The work will consist of two relatively independent stages: arranging an electric sharpener and manufacturing a knife holder that provides the required sharpening angle.

One of the necessary conditions for high-quality sharpening of knives is the stability of the sharpening tool. Therefore, as a base for an electric sharpener, we use a metal sheet of suitable size and thickness.

Using a tape measure, a core and a hammer, we mark the centers of four holes, repeating the holes on the electric sharpener plate. We drill holes according to the markings on a drilling machine and, using bolts and nuts, secure the electric sharpener to a metal base.

Using a pendulum saw, we cut off two pieces of square pipes pre-calculated in length, and one should fit freely, but without a large gap, into the other.

In a pipe of a smaller cross-section, we mill a through hole at one end, the diameter of which should be slightly larger than the diameter of the metal rod. In the second pipe, we also mark and drill a hole at one end for the locking bolt.

We weld a pipe of larger cross-section in the center to the base, opposite the fixed sharpener, in such a position that the fixing bolt looks outward and is on top.To prevent drops of molten metal, sparks and scale from welding from damaging the electric motor, we cover it with a welding blanket.

We insert the rod into the drilled hole in the pipe of a smaller cross-section strictly to the middle and weld it in this position to the pipe, having previously checked the perpendicularity of these mating parts with a right triangle.

If this has not been done in advance, remove the electric sharpener from the base and inspect the electrical box, after which we reinstall the sharpener in place and check its functionality.

We insert the pipe with the rod into the pipe welded to the base and using the bolt you can set the required height for sharpening a particular knife. This was the last stage of arranging the electric sharpener. Let's start the second phase of work.

For an electric sharpener, change the direction of rotation.

As already noted, the quality of knife sharpening, first of all, depends on ensuring a constant sharpening angle. The holder we are going to make is designed just for this.

We mark the metal blank in accordance with the intended dimensions of the three elements, which will ensure the capture and reliable holding of the knife blade at a given angle to the surface of the circle when sharpening.

We cut them with a pendulum saw with the addition of lubricant to improve the quality of the cut and the safety of the saw blade.

We clamp all three elements in a “package” in the vice of a milling machine and process the surfaces to the required size and, at each change of position, remove the burrs with a hand file.

On two blanks we form jaws to grip and hold the knife blade. To do this, we mill each of them to their size on one side.The third workpiece is milled on both sides to size. It will serve as the basis for attaching side grips with jaws to it.

On the part that will be in the middle, on the milled part we make markings for two holes, located symmetrically to the longitudinal axis closer to the edges and slightly offset towards the base. We drill them on a drilling machine.

Using this part as a sample, we mark response points on the other two workpieces using a drill and a thin drill bit.

Then we drill out the marked places with a large-diameter drill to a small depth (we make, a kind of, nest-recesses).

We screw into the holes of the central element two pins of the required length with the same output, which, when installing the side elements, will fit into the recesses and hold them, but do not interfere with the jaws, converge and diverge.

In the side jaw elements, in the geometric center, we mark and drill holes of the same diameter and use a hand tap to cut threads into them.

We mill the outer edges of the jaws to complete the appearance of the device and ease of use. We also remove the chamfers on both sides at the milling end of the central element so as not to interfere with the adjustment of the jaws.

In the center of the base of the central element we mark and drill a blind hole for the mandrel.

Mix two-component glue and use it to secure a mandrel of the required length in the blind hole. Let the compound set and harden. To do this, we fix the central element with the mandrel in a wooden vice.

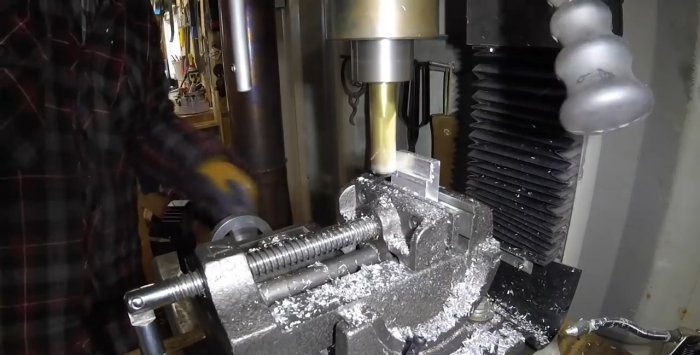

We clamp a metal rod of the calculated diameter in the lathe chuck and drill a hole in the center slightly larger than the diameter of the mandrel, periodically adding lubricant to the drilling area.

Then we cut off the cylinder with a height of about 10-12 mm and drill a hole on the side surface, followed by cutting the thread using a tap for the locking screw.

On one of the side elements, from the outside, we drill out a central hole to install the bolt head flush-mounted.

We finalize the surfaces of the device by processing it on a grinder, first with an endless sanding belt, and then with a nap tape.

All that remains is to assemble the elements of the adjustable holder together by screwing the connecting bolt into the jaws and securing the cylindrical ring to the mandrel, installing it in the right place using a locking screw.

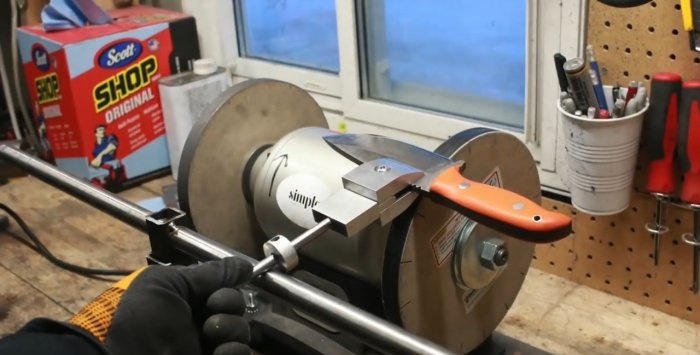

We clamp the knife blade in the jaws of the holder and set the required height of the transverse rod and the length of the mandrel by moving the cylindrical ring down or up and locking it where necessary with a special screw.

In order for the sharpening angle to remain the same along the entire length of the blade, it is enough to ensure that a cylindrical ring mounted on a mandrel slides along the surface of a rod installed horizontally in front of the electric sharpener wheels.

After a short sharpening without any tension, the knife easily cuts a sheet of writing paper in weight, which confirms its excellent sharpening.

Of course, this is not difficult for an experienced sharpener to achieve even when working manually. For everyone else, maintaining the required sharpening angle will be quite difficult. Will the problem of dull knives remain insoluble for them?

There are three ways out of this predicament: learn to sharpen knives, but this will require a lot of time, patience and effort; turn to a professional for help every time and pay for his expensive service; make your own knife sharpener and don’t worry about the sharpening angle.

Below we will consider a method for manufacturing a device for sharpening knives based on an electric sharpener with two abrasive wheels.

Will need

So that the work does not take a lot of effort and time, it is good to have in stock: a welding machine, machines (drilling, milling and turning), a pendulum saw, a drill, a grinder, wrenches, marking tools, etc.

In addition to the already mentioned electric sharpener, you need to stock up on materials and components:

- metal sheet 10 mm thick;

- square pipes (two pieces of adjacent sizes);

- a round metal rod up to 400 mm long and 15-20 mm in diameter;

- threaded fasteners (bolts, nuts, washers), etc.

Making a knife sharpener

The work will consist of two relatively independent stages: arranging an electric sharpener and manufacturing a knife holder that provides the required sharpening angle.

Arrangement of the sharpener

One of the necessary conditions for high-quality sharpening of knives is the stability of the sharpening tool. Therefore, as a base for an electric sharpener, we use a metal sheet of suitable size and thickness.

Using a tape measure, a core and a hammer, we mark the centers of four holes, repeating the holes on the electric sharpener plate. We drill holes according to the markings on a drilling machine and, using bolts and nuts, secure the electric sharpener to a metal base.

Using a pendulum saw, we cut off two pieces of square pipes pre-calculated in length, and one should fit freely, but without a large gap, into the other.

In a pipe of a smaller cross-section, we mill a through hole at one end, the diameter of which should be slightly larger than the diameter of the metal rod. In the second pipe, we also mark and drill a hole at one end for the locking bolt.

We weld a pipe of larger cross-section in the center to the base, opposite the fixed sharpener, in such a position that the fixing bolt looks outward and is on top.To prevent drops of molten metal, sparks and scale from welding from damaging the electric motor, we cover it with a welding blanket.

We insert the rod into the drilled hole in the pipe of a smaller cross-section strictly to the middle and weld it in this position to the pipe, having previously checked the perpendicularity of these mating parts with a right triangle.

If this has not been done in advance, remove the electric sharpener from the base and inspect the electrical box, after which we reinstall the sharpener in place and check its functionality.

We insert the pipe with the rod into the pipe welded to the base and using the bolt you can set the required height for sharpening a particular knife. This was the last stage of arranging the electric sharpener. Let's start the second phase of work.

For an electric sharpener, change the direction of rotation.

Making a knife holder

As already noted, the quality of knife sharpening, first of all, depends on ensuring a constant sharpening angle. The holder we are going to make is designed just for this.

We mark the metal blank in accordance with the intended dimensions of the three elements, which will ensure the capture and reliable holding of the knife blade at a given angle to the surface of the circle when sharpening.

We cut them with a pendulum saw with the addition of lubricant to improve the quality of the cut and the safety of the saw blade.

We clamp all three elements in a “package” in the vice of a milling machine and process the surfaces to the required size and, at each change of position, remove the burrs with a hand file.

On two blanks we form jaws to grip and hold the knife blade. To do this, we mill each of them to their size on one side.The third workpiece is milled on both sides to size. It will serve as the basis for attaching side grips with jaws to it.

On the part that will be in the middle, on the milled part we make markings for two holes, located symmetrically to the longitudinal axis closer to the edges and slightly offset towards the base. We drill them on a drilling machine.

Using this part as a sample, we mark response points on the other two workpieces using a drill and a thin drill bit.

Then we drill out the marked places with a large-diameter drill to a small depth (we make, a kind of, nest-recesses).

We screw into the holes of the central element two pins of the required length with the same output, which, when installing the side elements, will fit into the recesses and hold them, but do not interfere with the jaws, converge and diverge.

In the side jaw elements, in the geometric center, we mark and drill holes of the same diameter and use a hand tap to cut threads into them.

We mill the outer edges of the jaws to complete the appearance of the device and ease of use. We also remove the chamfers on both sides at the milling end of the central element so as not to interfere with the adjustment of the jaws.

In the center of the base of the central element we mark and drill a blind hole for the mandrel.

Mix two-component glue and use it to secure a mandrel of the required length in the blind hole. Let the compound set and harden. To do this, we fix the central element with the mandrel in a wooden vice.

We clamp a metal rod of the calculated diameter in the lathe chuck and drill a hole in the center slightly larger than the diameter of the mandrel, periodically adding lubricant to the drilling area.

Then we cut off the cylinder with a height of about 10-12 mm and drill a hole on the side surface, followed by cutting the thread using a tap for the locking screw.

On one of the side elements, from the outside, we drill out a central hole to install the bolt head flush-mounted.

We finalize the surfaces of the device by processing it on a grinder, first with an endless sanding belt, and then with a nap tape.

All that remains is to assemble the elements of the adjustable holder together by screwing the connecting bolt into the jaws and securing the cylindrical ring to the mandrel, installing it in the right place using a locking screw.

Fixture test

We clamp the knife blade in the jaws of the holder and set the required height of the transverse rod and the length of the mandrel by moving the cylindrical ring down or up and locking it where necessary with a special screw.

In order for the sharpening angle to remain the same along the entire length of the blade, it is enough to ensure that a cylindrical ring mounted on a mandrel slides along the surface of a rod installed horizontally in front of the electric sharpener wheels.

After a short sharpening without any tension, the knife easily cuts a sheet of writing paper in weight, which confirms its excellent sharpening.

Watch the video

Similar master classes

Particularly interesting

Comments (5)